Preparation method of bis-(5-formyl furfuryl)ether and polyamide material

A technology of formyl furfuryl and hydroxymethyl furfural, applied in the field of plastic processing, can solve the problems of limited large-scale application, poor hydrothermal stability, amorphization of pore walls, etc., and achieves good application prospects, small grain size, and pore size range. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

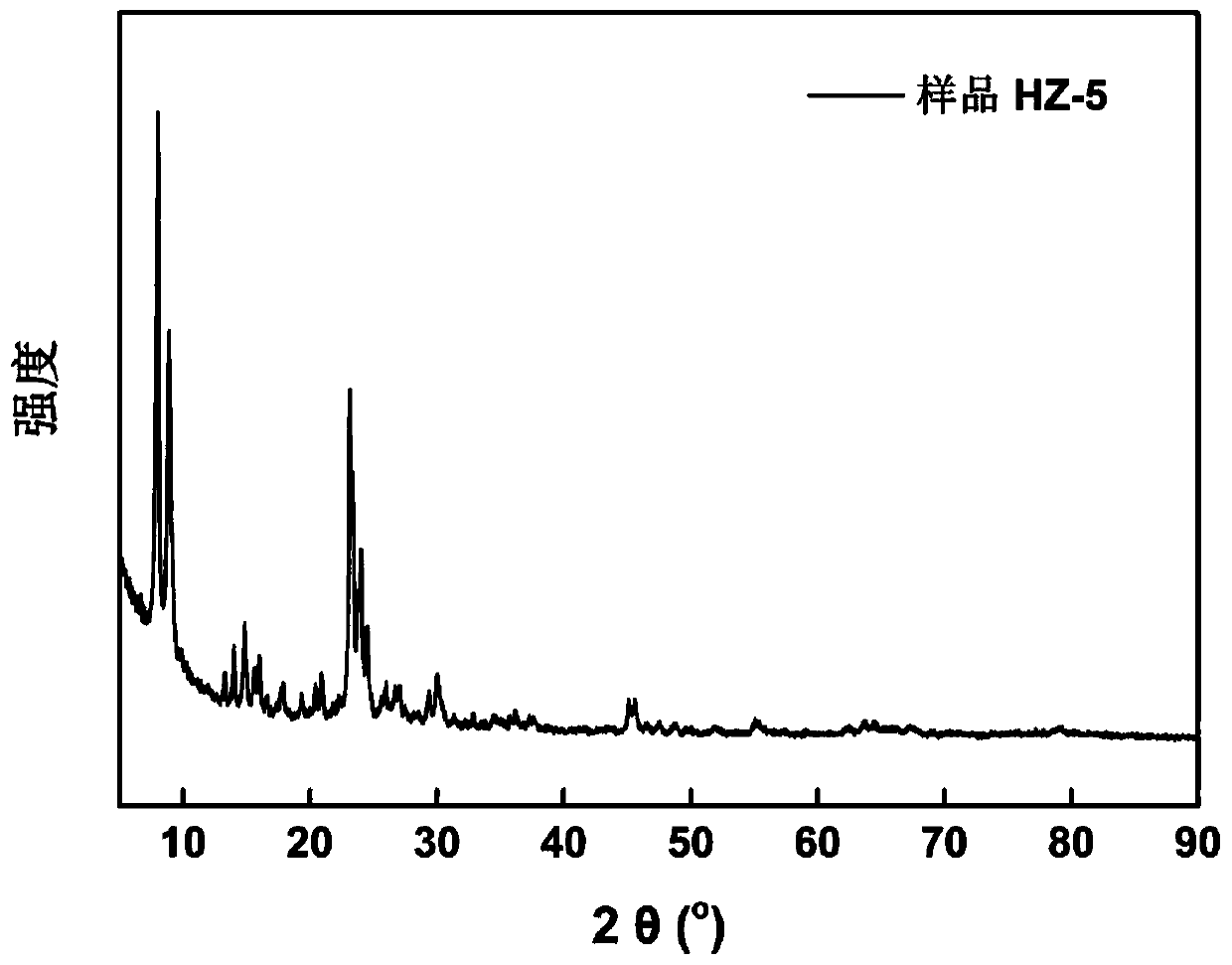

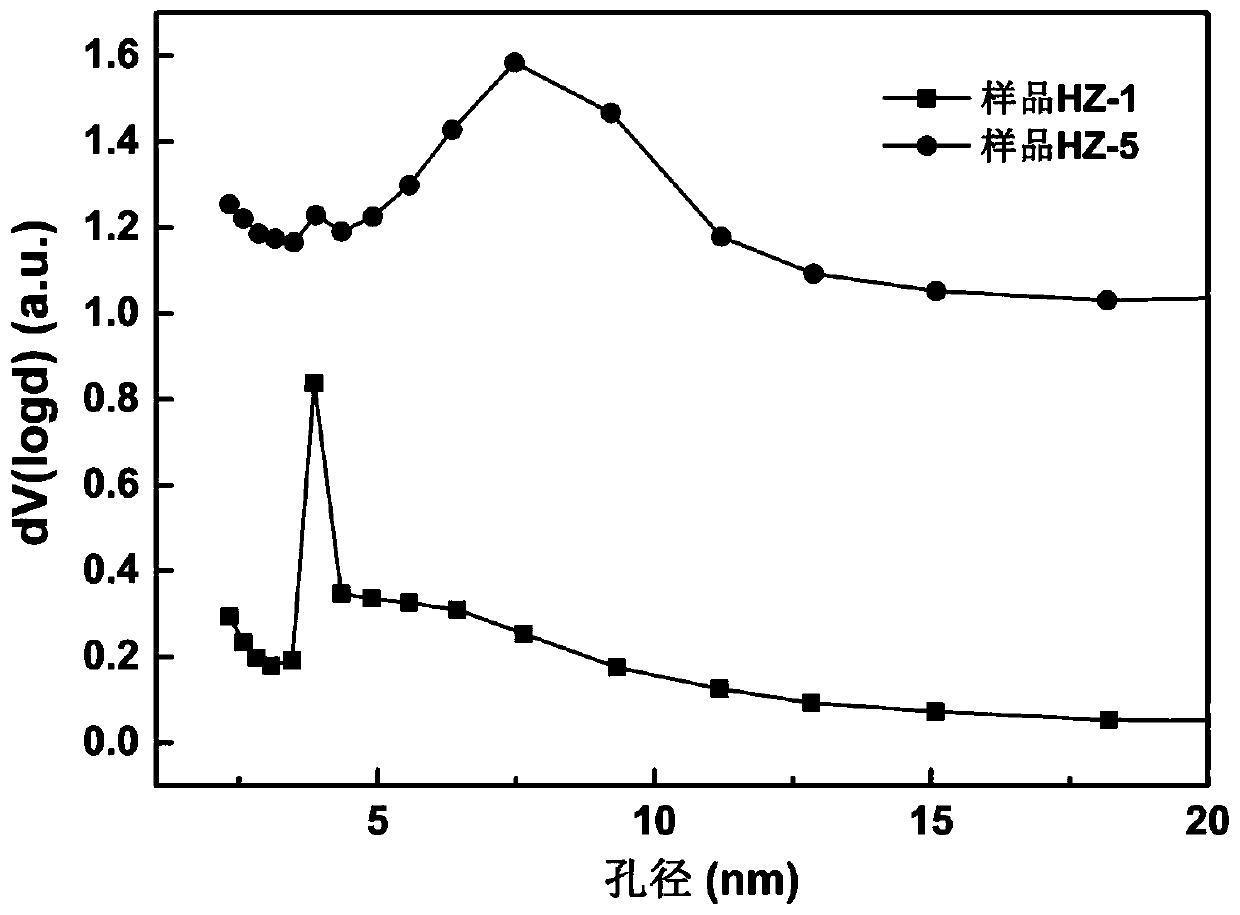

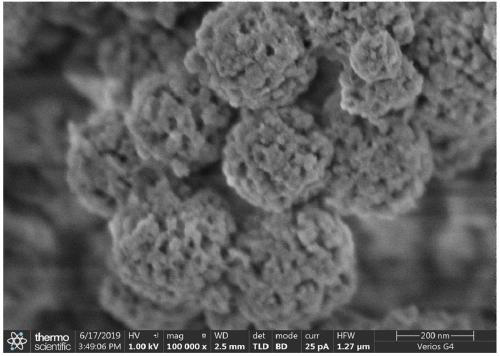

[0096] Embodiment 1 sample HZ-1 preparation

[0097] Add aluminum isopropoxide and tetrapropylammonium hydroxide to 60mL ethanol, stir at room temperature to form a clear solution A; add tetraethyl orthosilicate and hexadecyltrimethoxysilane to 30mL ethanol, Stir to form a clear solution B; add solution B dropwise to solution A, stir vigorously (1000 rpm) to form a uniform gel C, and the molar ratio of each material is 1SiO 2 :0.005Al 2 o 3 :0.2TPAOH:0.05HTS:30EtOH. The obtained gel C was dried in an oven at 25°C for 48 hours to obtain a dry gel, transferred to a hydrothermal kettle, added 70mL of deionized water, and crystallized in an oven at 170°C for 90 hours under steam-assisted conditions; Rinse the deionized product with deionized water, put the solid product in an oven, dry it at 100°C for 10 hours, then place it in a muffle furnace, and bake it at 550°C for 5 hours to obtain a hierarchical pore with a silicon-aluminum ratio of 100 Molecular sieve HZ-1.

Embodiment 2

[0098] Embodiment 2 sample HZ-2 preparation

[0099] Add aluminum isopropoxide and tetrapropylammonium hydroxide to 50mL ethanol, stir at room temperature to form a clear solution A; add tetraethyl orthosilicate and hexadecyltrimethoxysilane to 50mL ethanol, Stir to form a clear solution B; add solution B dropwise to solution A, stir vigorously (1000 rpm) to form a uniform gel C, and the molar ratio of each material is 1SiO 2 :0.01Al 2 o 3 :0.2TPAOH:0.05HTS:30EtOH. The obtained gel C was dried in an oven at 25°C for 48 hours to obtain a dry gel, transferred to a hydrothermal kettle, added 70mL of deionized water, and crystallized in an oven at 180°C for 80 hours under steam-assisted conditions; Rinse the deionized product with deionized water, put the solid product in an oven, dry at 100°C for 5 hours, then place it in a muffle furnace, and bake it at 550°C for 10 hours to obtain a hierarchical porous material with a silicon-aluminum ratio of 50 Molecular sieve HZ-2.

Embodiment 3

[0100] Embodiment 3 sample HZ-3 preparation

[0101] Add aluminum isopropoxide and tetrapropylammonium hydroxide to 60mL ethanol, stir at room temperature to form a clear solution A; add tetraethyl orthosilicate and hexadecyltrimethoxysilane to 40mL ethanol, Stir to form a clear solution B; add solution B dropwise to solution A, stir vigorously (1000 rpm) to form a uniform gel C, and the molar ratio of each material is 1SiO 2 :0.02Al 2 o 3 :0.2TPAOH:0.05HTS:30EtOH. The obtained gel C was dried in an oven at 30°C for 36 hours to obtain a dry gel, transferred to a hydrothermal kettle, added 60mL of deionized water, and crystallized in an oven at 190°C for 80 hours under steam-assisted conditions; Rinse the deionized product with deionized water, put the solid product in an oven, dry at 100°C for 5 hours, then place it in a muffle furnace, and bake it at 550°C for 7 hours to obtain a hierarchical porous material with a silicon-aluminum ratio of 25 Molecular sieve HZ-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com