Method and device for treating high-concentration organic chemical-industrial sewage

A chemical wastewater, high-concentration technology, used in oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as poor treatment effect, improve purification efficiency, prevent the loss of dominant bacteria, The effect of enhancing the degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

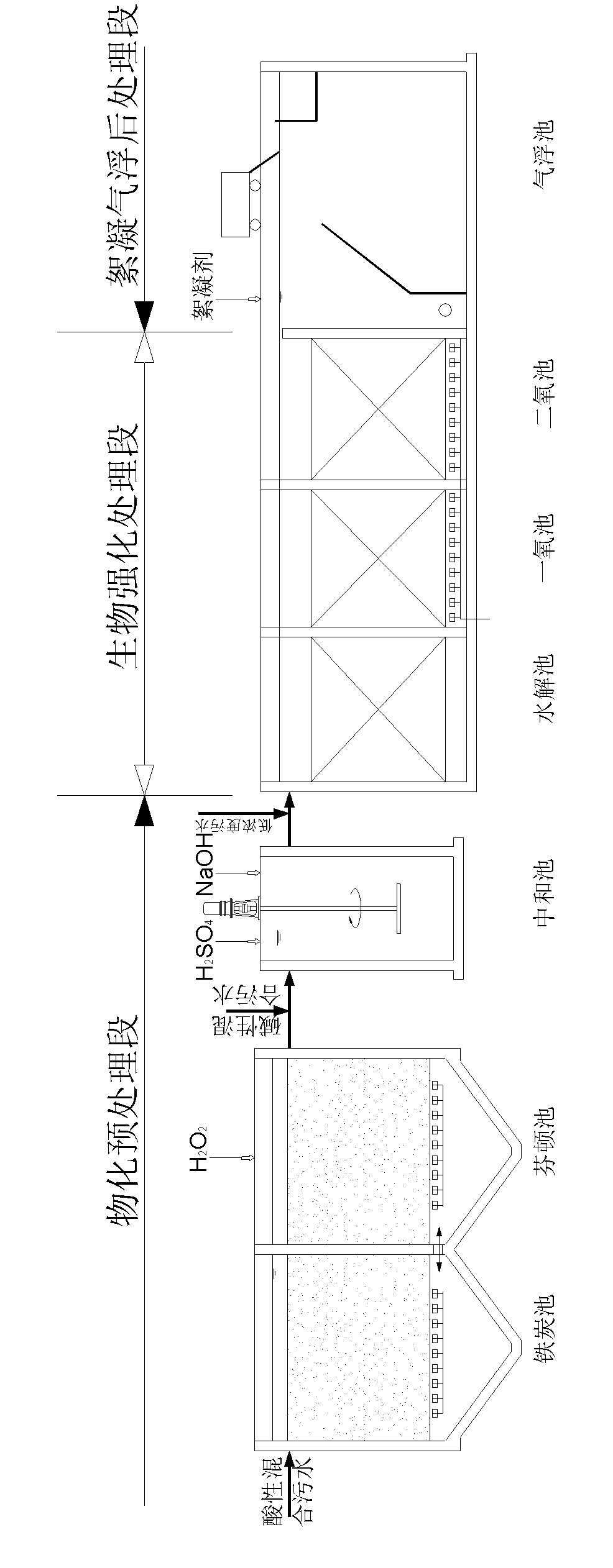

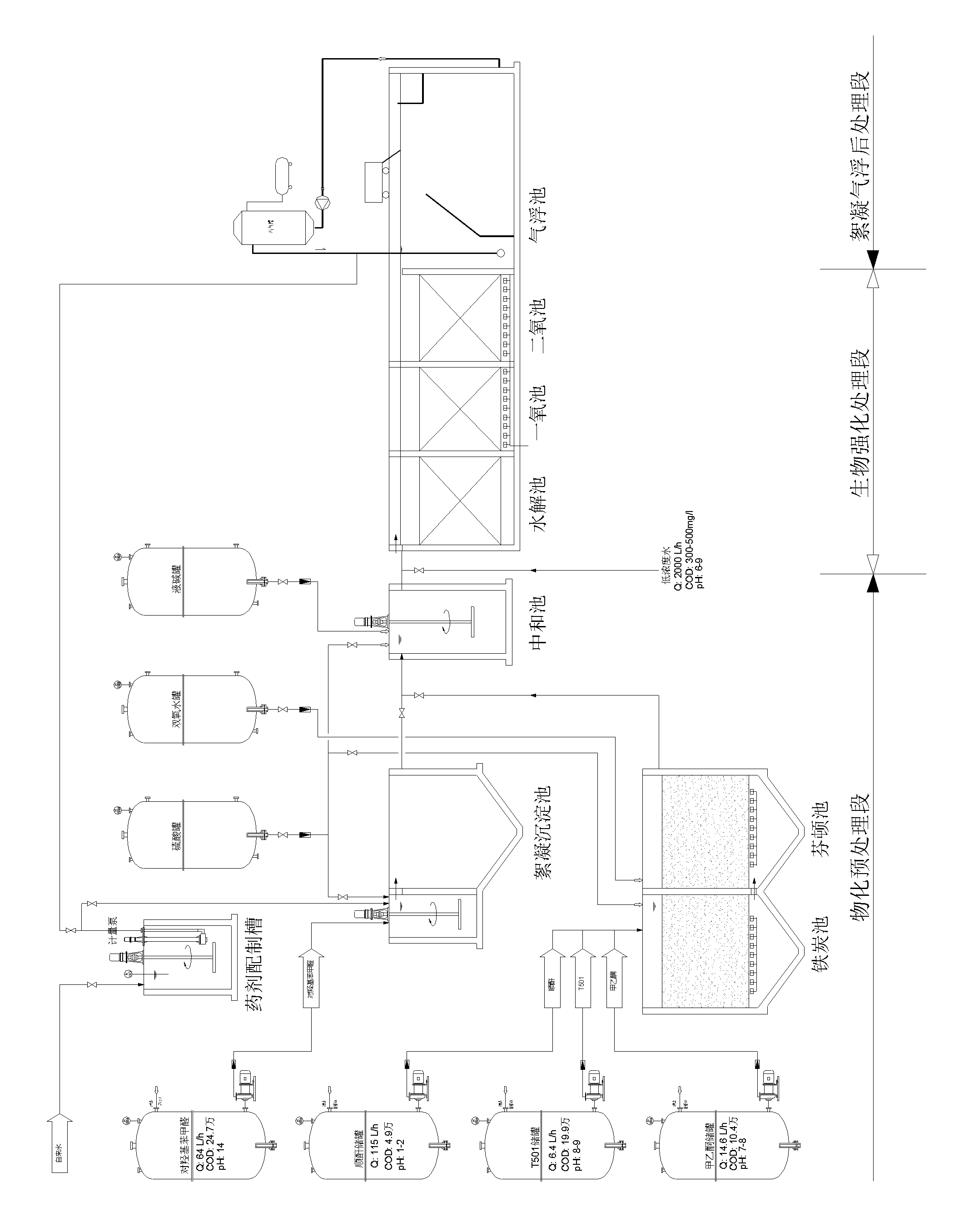

Method used

Image

Examples

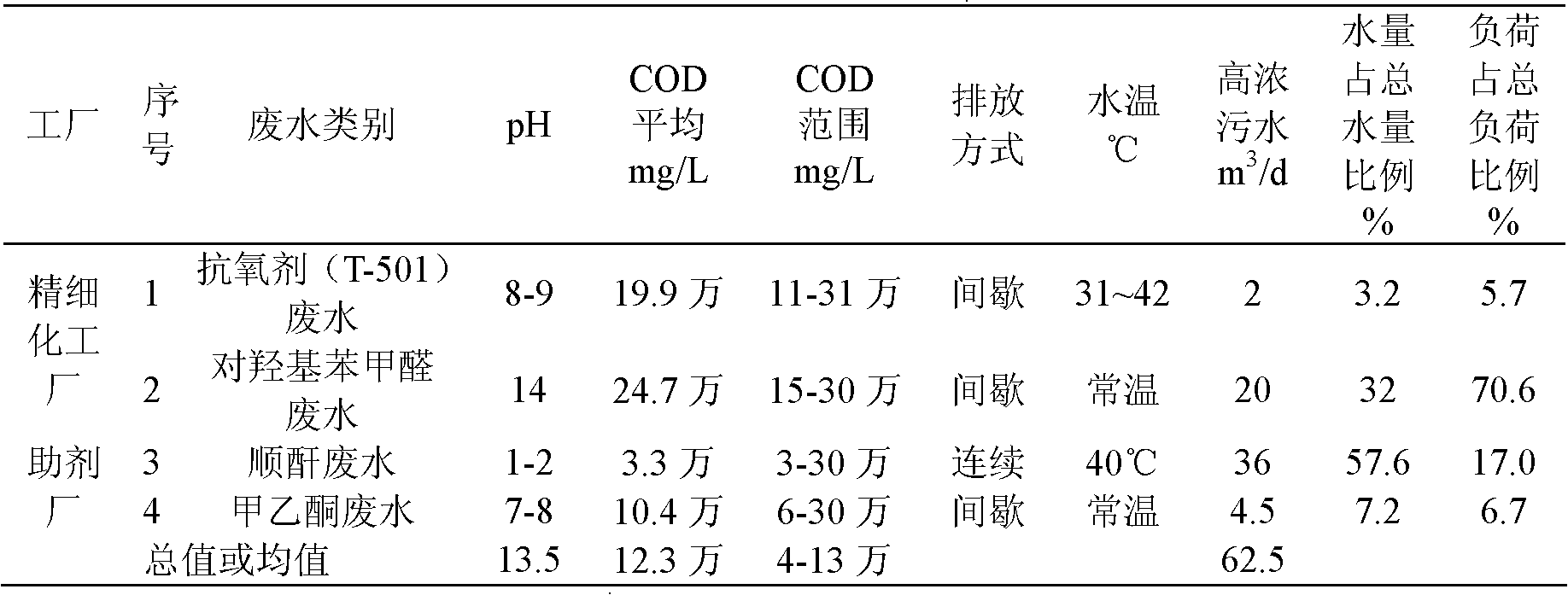

Embodiment 1

[0080] 1. The total inflow of high-concentration organic chemical sewage is 200L / h, and the antioxidant: p-hydroxybenzaldehyde: maleic anhydride: methyl ethyl ketone is influent at a ratio of 4:40:72:9, that is, the antioxidant is 6.4L / h. p-hydroxybenzaldehyde 64L / h, maleic anhydride 115L / h, methyl ethyl ketone 14.6L / h;

[0081] 2. Antioxidant, maleic anhydride, methyl ethyl ketone three kinds of acidic (pH2.0) sewage are lifted from the sewage storage tank by the metering pump to the iron carbon pool according to the flow rate (Fe: C = 1: 1.5 (weight ratio), the iron carbon bed is high 500mm) for micro-electrolysis reaction, the COD value of the mixed sewage is 53,000 mg / L, and the bottom of the iron-carbon pool is aerated and stirred at the same time, and the total reaction time is 150 minutes;

[0082] 3. After the reaction in the iron-carbon pool, the effluent enters the Fenton oxidation pool for oxidation reaction, and the H 2 o 2 The dosage is 6mL·L -1 , using the bot...

Embodiment 2

[0090] Adopt the same method as embodiment 1 to carry out sewage treatment, the difference is that in the step 6, adding bio-augmentation engineering bacteria in the hydrolytic acidification tank is (1.10 8 -10 9 Colonies / mL of GW1, GW2, GW5 strains mixed bacterial solution 10kg; ② petrochemical sewage plant sludge 500kg); adding bio-augmentation engineering bacteria to the contact oxidation tank is (①10 8 -10 9 Colonies / mL of GW1, GW2, GW5 strains mixed bacterial solution 16kg; ② petrochemical sewage plant sludge 500kg). Obtained the sewage treatment effect identical with embodiment 1.

Embodiment 3

[0092] Adopt the same method as Example 1 to carry out sewage treatment, the difference is that in the hydrolytic acidification tank in step 6, add bio-augmentation engineering bacteria as (1. Jiangsu Lvke Biotechnology Co., Ltd. EM bacteria freeze-dried powder 5kg (effective Viable bacteria ≥5×10 9 CFU / g); ② petrochemical sewage plant sludge 500kg); adding bio-enhanced engineering bacteria to the contact oxidation tank (① 5kg of EM bacteria freeze-dried powder purchased from the market (effective live bacteria ≥ 5× 10 9 CFU / g); ② petrochemical sewage plant sludge 500kg). Obtained the sewage treatment effect identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com