Method for preparing PbSe quantum dot doped fiber material

A technology of doping optical fibers and quantum dots, applied in the field of optical communication technology and nanomaterial preparation, can solve the problems of high cost, poor chemical stability and poor mechanical properties, and achieve the effects of low price, excellent performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 58% SiO according to glass formulation 2 , 4% B 2 o 3 , 4% Al 2 o 3 , 9% ZnO, 2% AlF 3 , 16%Na 2 O, 3% PbO, 3% Se and 1% C (wt.%), weighed analytically pure SiO 2 : 29.0g, B 2 o 3 : 2.0g, Al 2 o 3 : 2.0g, ZnO: 4.5g, Na 2 CO 3: 13.7g, PbO: 1.5g; chemically pure AlF 3 ·3H 2 O: 1.6g, Se: 1.5g and C: 0.5g. Put the above chemical raw materials in a ball mill and stir evenly, take them out and place them in a closed corundum crucible, then put them into a box-type electric furnace, melt at a high temperature of 1400°C for 1 hour, then pour the melt on a metal mold, and cool it rapidly to room temperature. A light brown glass was obtained.

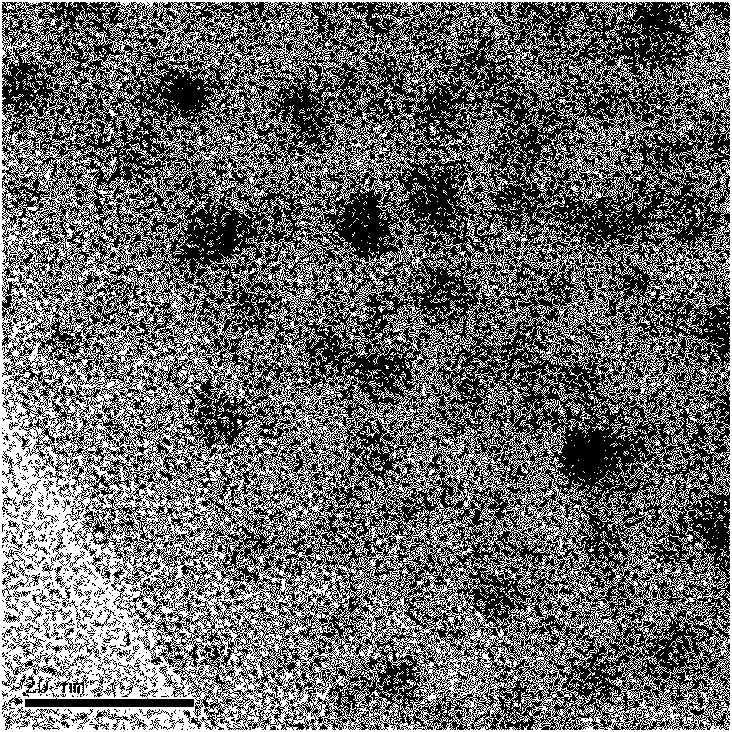

[0033] Then put the glass into a box-type electric furnace, heat-treat at 550°C for 5 hours, take it out and cool it in air to room temperature, and obtain a quantum dot-doped optical fiber material with a PbSe quantum dot size of about 6nm. The transmission electron microscope figure (scale is 20nm) of the prepared PbSe qu...

Embodiment 2

[0035] 58% SiO according to glass formulation 2 , 4% B 2 o 3 , 4%Al 2 o 3 , 9% ZnO, 2% AlF 3 , 16%Na 2 O, 3% PbO, 3% Se and 1% C (wt.%), weighed analytically pure SiO 2 : 29.0g, B 2 o 3 : 2.0g, Al 2 o 3 : 2.0g, ZnO: 4.5g, Na 2 CO 3 : 13.7g, PbO: 1.5g; chemically pure AlF 3 ·3H 2 O: 1.6g, Se: 1.5g and C: 0.5g. Put the above chemical raw materials in a ball mill and stir evenly, take them out and place them in a closed corundum crucible, then put them into a box-type electric furnace, melt at a high temperature of 1400°C for 1 hour, then pour the melt on a metal mold, and cool it rapidly to room temperature. A light brown glass was obtained.

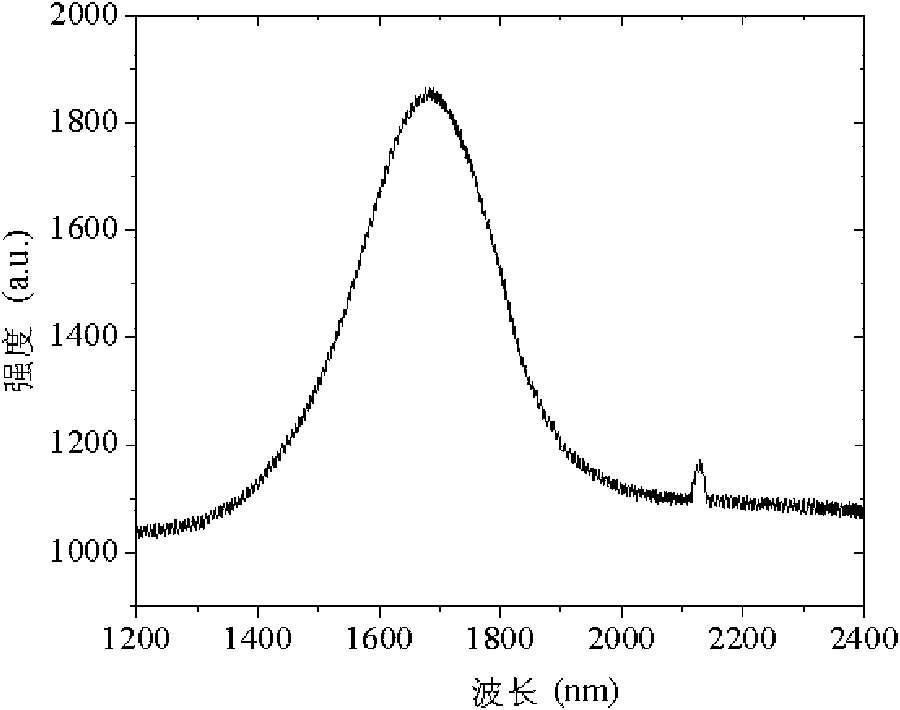

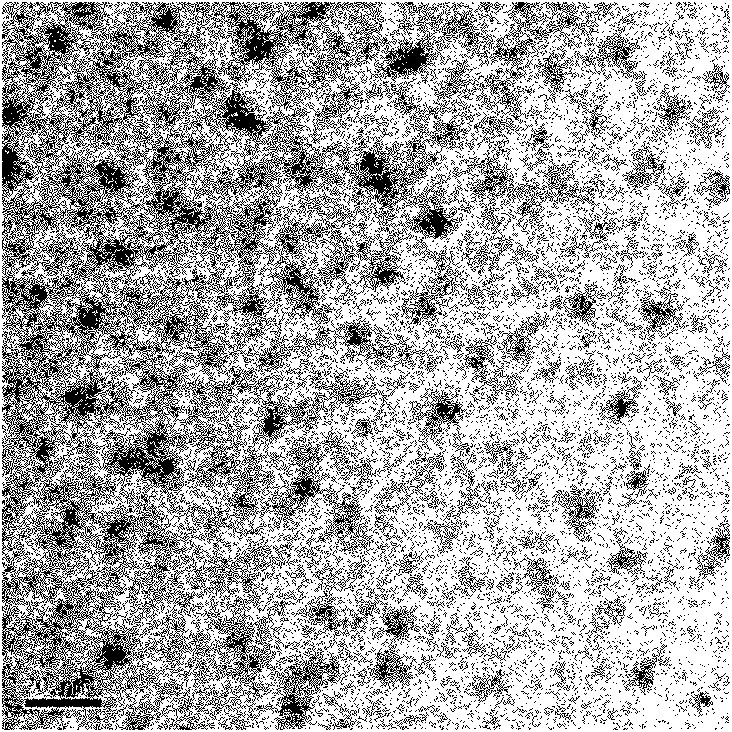

[0036] Then put the glass into a box-type electric furnace, heat-treat at 600°C for 5 hours, take it out and cool it to room temperature in the air, and you can get a quantum dot-doped optical fiber material with a PbSe quantum dot size of about 9nm. The transmission electron microscope figure (scale is 20nm) of the prepare...

Embodiment 3

[0038] 58% SiO according to glass formulation 2 , 4% B 2 o 3 , 4% Al 2 o 3 , 9% ZnO, 2% AlF 3 , 16%Na 2 O, 3% PbO, 3% Se and 1% C (wt.%), weighed analytically pure SiO 2 : 29.0g, B 2 o 3 : 2.0g, Al 2 o 3 : 2.0g, ZnO: 4.5g, Na 2 CO 3 : 13.7g, PbO: 1.5g; chemically pure AlF 3 ·3H 2 O: 1.6g, Se: 1.5g and C: 0.5g. Put the above chemical raw materials in a ball mill and stir evenly, take them out and place them in a closed corundum crucible, then put them into a box-type electric furnace, melt at a high temperature of 1400°C for 1 hour, then pour the melt on a metal mold, and cool it rapidly to room temperature. A light brown glass was obtained.

[0039] Then put the glass into a box-type electric furnace, heat-treat at 650°C for 5 hours, take it out and cool it to room temperature in the air, and obtain a quantum dot-doped optical fiber material with a PbSe quantum dot size of about 13nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com