High hydroxy alkyd resin for polyurethane curing agent and preparation method thereof

A technology of polyurethane curing agent and high-hydroxy alkyd, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced effective NCO group content, reduced cross-linking reactivity, and reduced hardness of curing agent to achieve effective NCO Increased content, good cross-linking density, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with specific embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

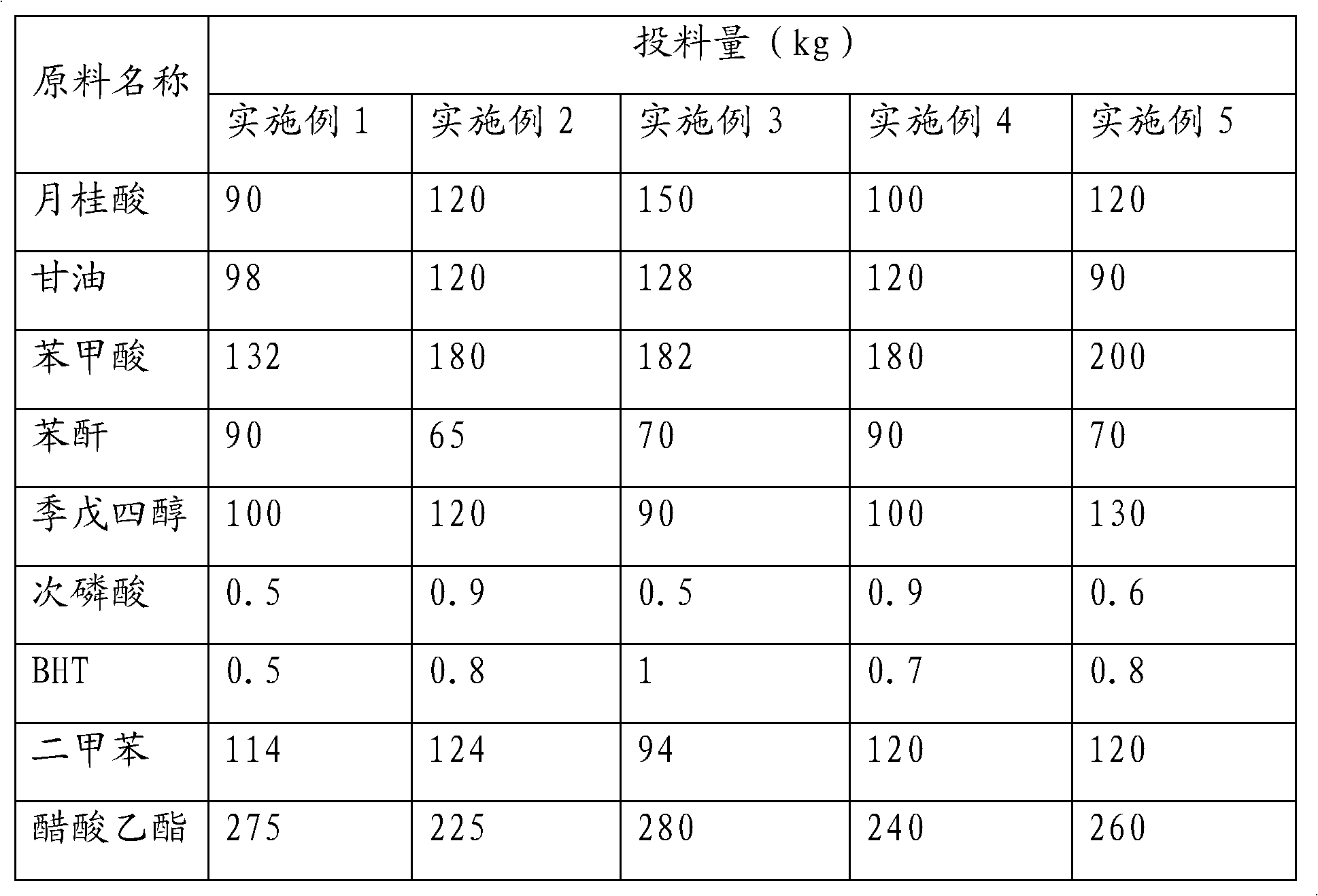

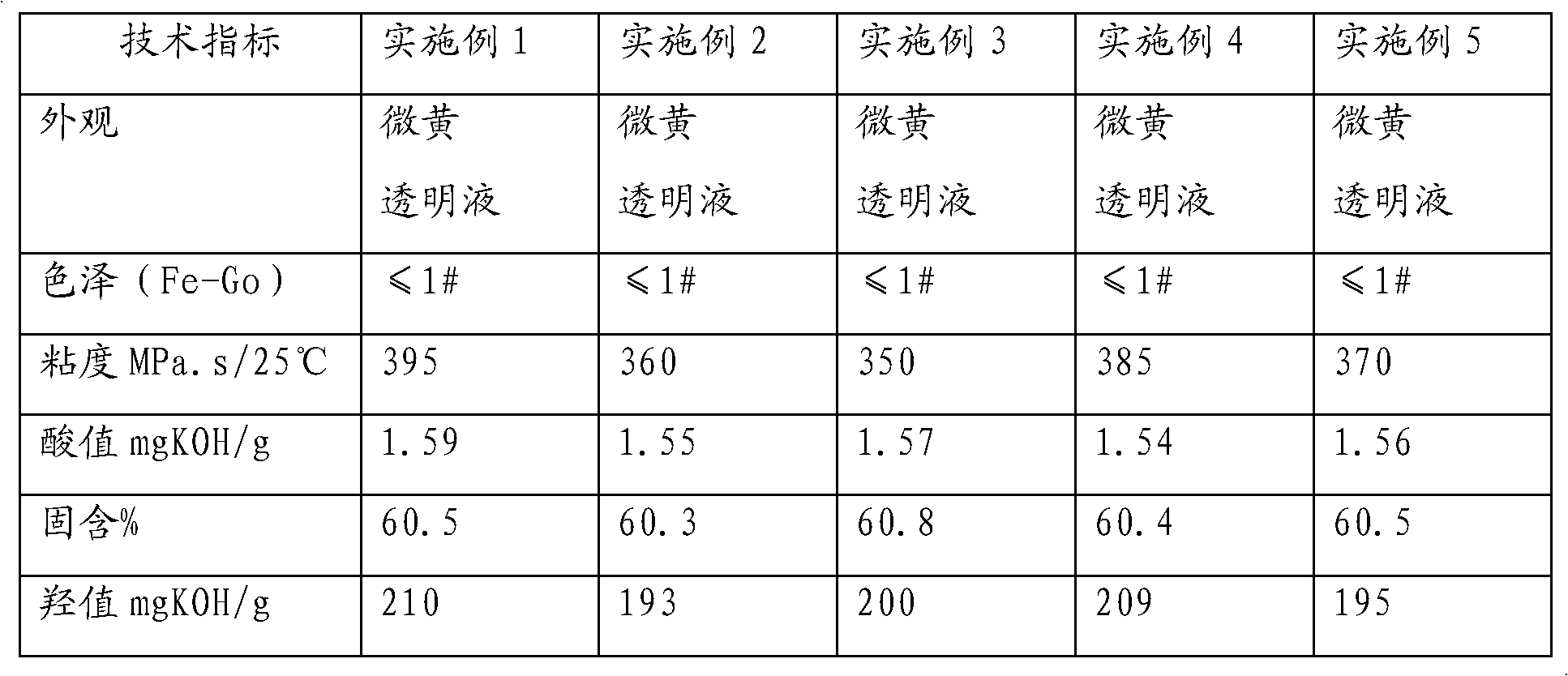

[0046] It should be noted that: the lauric acid, benzoic acid, phthalic anhydride, pentaerythritol, glycerol, hypophosphorous acid, 2,6-di-tert-butyl-4-methylphenol, xylene and ethyl acetate used in the following examples are domestic Industrial grade raw materials.

[0047] The preparation method of the high hydroxyl alkyd resin of following embodiment all adopts the identical process that comprises following steps, just the proportioning difference of each raw material:

[0048] 1. Pre-pass N into a clean reactor 2 ↑5min (flow: 4m 3 / h);

[0049] 2. Add lauric acid, glycerin, benzoic acid, phthalic anhydride, pentaerythritol, hypophosphorous acid, 2,6-di-tert-butyl-4-methylphenol, xylene in sequence according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com