Ceramic transfer digital printing ink-jet ink and using method thereof

An inkjet ink and digital printing technology, applied in ink, applications, household appliances, etc., can solve the problems of clogging inkjet printing heads, large density differences, shortening the working life of printing heads, etc., and meet high technical requirements and quality stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

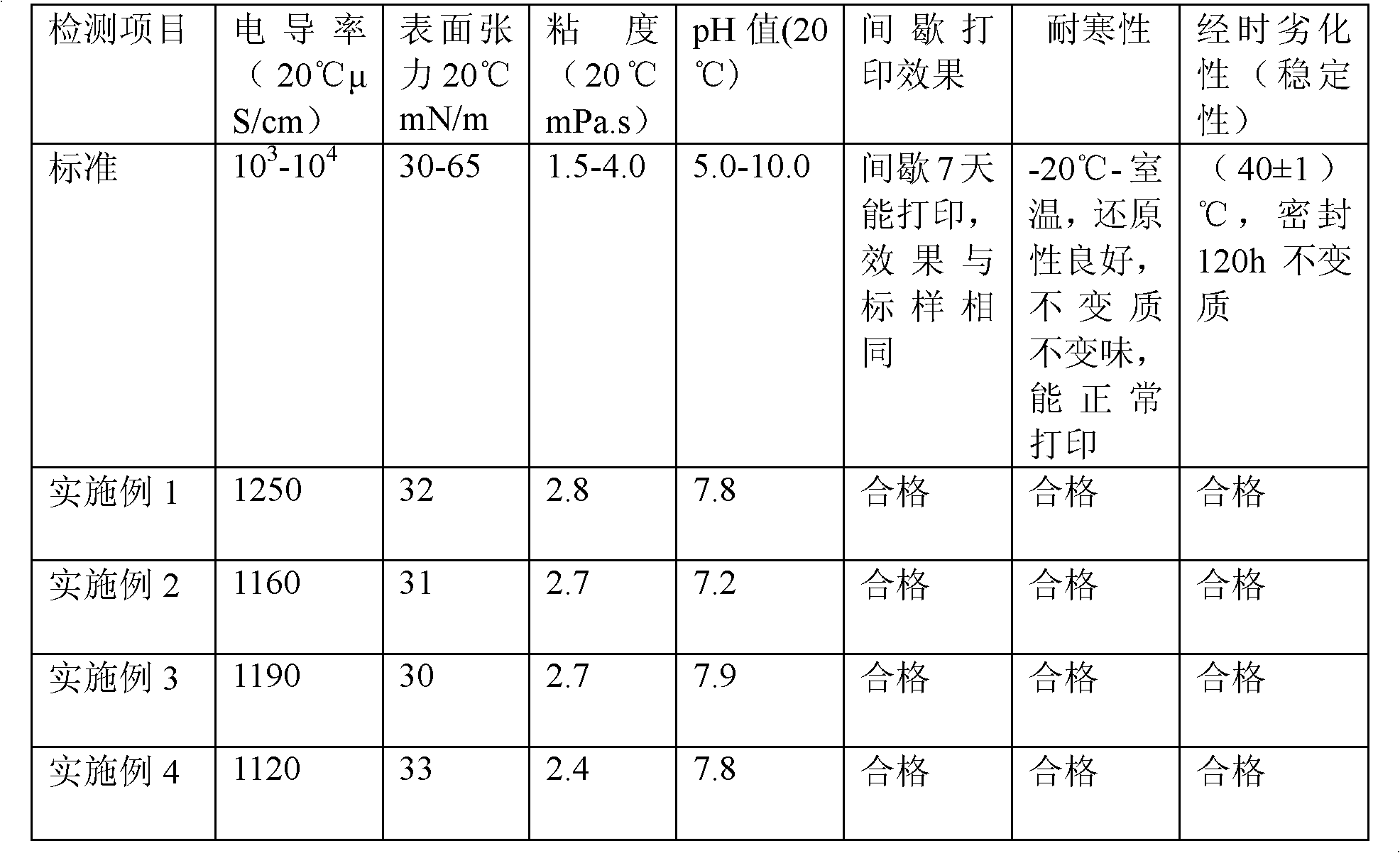

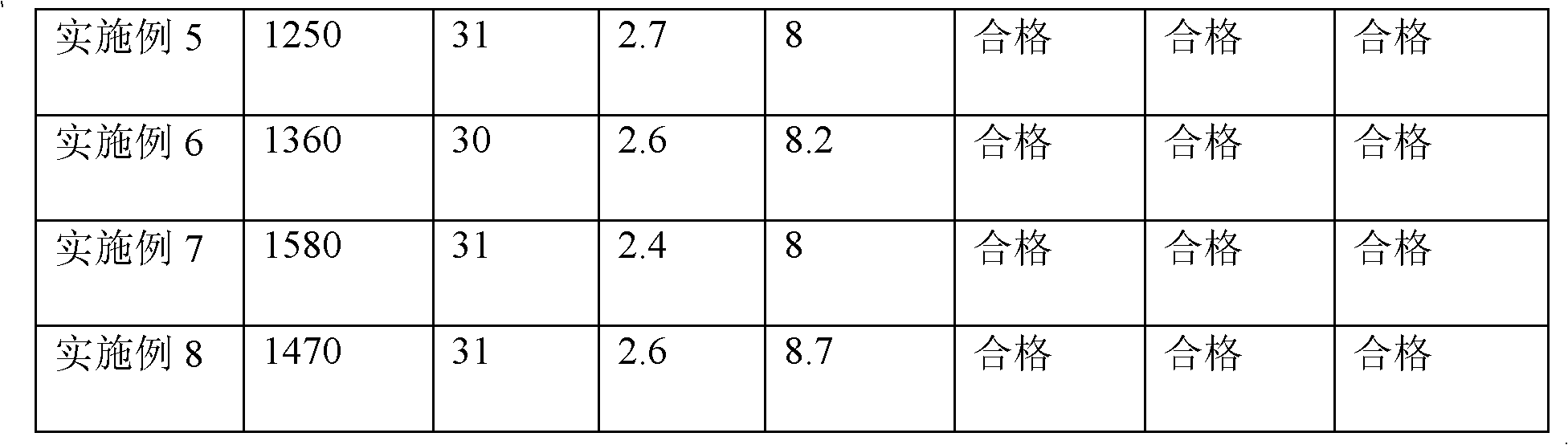

Examples

Embodiment 1

[0023] Ceramic transfer digital printing inkjet ink, which is composed of the following components according to weight percentage: inorganic pigment black Co-Cr-Fe 10%, inorganic pigment black Fe-Cr-Mn 6%, UDN dispersant 20%, Surfynol-465 surface tension modifier 2%, 5-chloro-2-methyl-4-isothiazolin-3-one 1%, acrylic resin 2%, monoethanolamine 0.1%, the rest is Ionized water; the above components are mixed uniformly in proportion and then filtered through a 0.45 micron filter membrane to obtain the product. In this embodiment, the product produced by Kleinanthrene is preferred. UDN dispersant, Surfynol-465 surface tension modifier produced by American Gas Chemical Company.

Embodiment 2

[0025] Ceramic transfer digital printing inkjet ink, which consists of the following components according to weight percentage: inorganic pigment vanadium zirconium blue Zr-Si-V 10%, UDN dispersant 12%, Surfynol-465 surface tension modifier 1.2%, 5-chloro-2-methyl-4-isothiazolin-3-one 0.5%, triethylene glycol methyl ether 15%, triethanolamine 1% , 1% lactic acid, and the rest are deionized water; the above components are mixed uniformly in proportion and then filtered through a 0.45 micron filter membrane to obtain the product. UDN dispersant, Surfynol-465 surface tension modifier produced by American Gas Chemical Company.

Embodiment 3

[0027] Inkjet ink for ceramic transfer digital printing, which consists of the following components according to weight percentage: inorganic pigment pink Sn-Cr-Ca-Si 12%, UDN dispersant 15%, Surfynol-465 surface tension modifier 0.8%, 5-chloro-2-methyl-4-isothiazolin-3-one 0.5%, ethylene glycol benzyl ether 10%, furfuryl alcohol 5%, a Ethanolamine 0.1%, the rest is deionized water; the above components are mixed evenly in proportion and then filtered through a 0.45 micron filter membrane to obtain the product. UDN dispersant, Surfynol-465 surface tension modifier produced by American Gas Chemical Company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com