Single-piston three-cavity pneumatic reset type brake and implementation method thereof

A brake and single-piston technology, applied in the direction of brake types, brake actuators, engine components, etc., can solve the problems that affect the start-up speed and automatic start-up success rate of the unit, the unit cannot be connected to the grid for power generation, and the brake cannot be reset. The effect of value enhancement, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

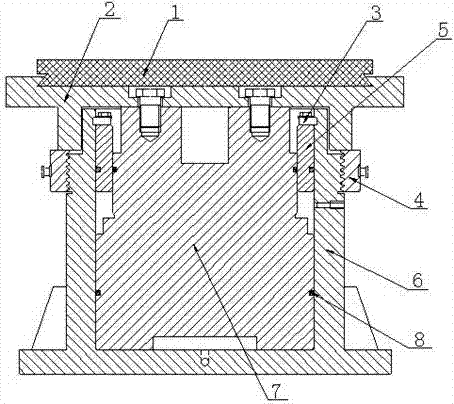

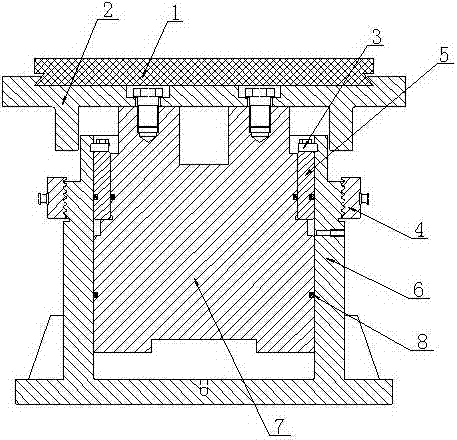

[0034] like Figure 4 ~ Figure 6 As shown, a single-piston three-chamber pneumatic return brake includes a piston cylinder 6 with a built-in piston 7. The upper end of the piston cylinder 6 is provided with a braking device fixedly connected to the piston 7. Between the piston 7 and the piston cylinder 6 A bushing 5 is provided, and the upper end of the bushing 5 is connected to the piston cylinder 6 through the bushing fixing plate 3, and is respectively arranged between the piston 7 and the piston cylinder 6, the piston 7 and the bushing 5, and the bushing 5 and the piston cylinder 6. There is a circular sealing ring 8 and a "Y" type sealing ring 9, and a locking device 4 is provided on the outer wall of the piston cylinder 6, and an isolation chamber 10 communicating with the outside atmosphere is also provided between the piston 7 and the piston cylinder 6, The side wall of the piston cylinder 6 facing the isolation chamber 10 is provided with a through hole 11 , and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com