A kind of electromagnetic cooker and its manufacturing method

A technology of induction cooker and inductance, which is applied to household stoves/stoves, electric heating fuels, household heating, etc., can solve the problems of reducing the heating efficiency of coil disks, unfavorable thin design of products, aging of electrical components of induction cookers, etc., and achieves calorific value The effect of reducing, small internal resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

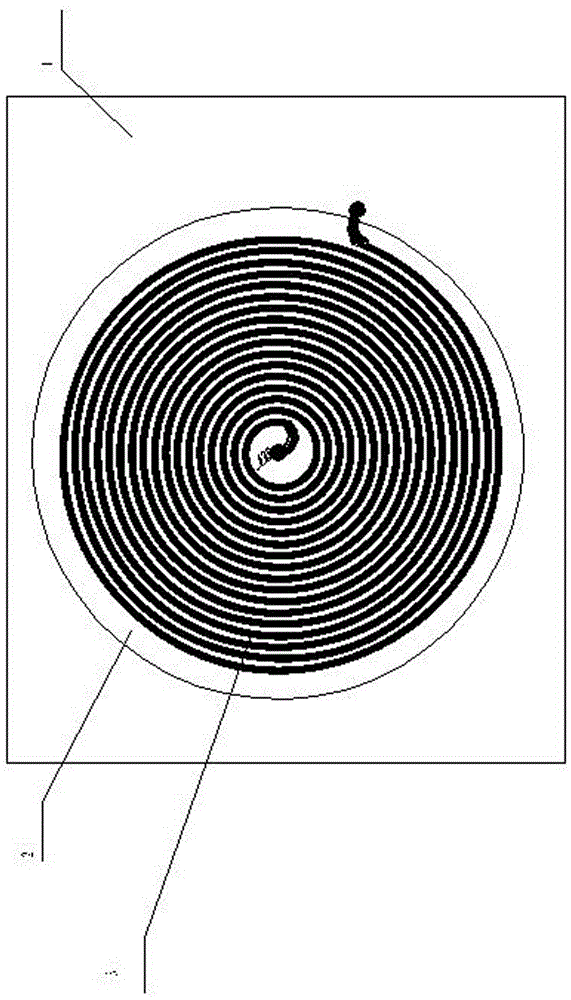

[0023] An induction cooker includes a panel 1, the panel 1 includes a substrate and a thick film coil combined with it [y3], the substrate is made of non-metallic material, and the thick film coil is as figure 1 As shown, the thick-film coil is spirally formed on the substrate in a single-layer or multi-layer manner by using a thick-film conductive paste by screen printing, and the shape is sheet-like.

[0024] Its manufacture method is as follows steps:

[0025] (1) Print the first layer of conductive silver paste on the substrate and sinter at high temperature:

[0026] (2) Printing the first insulating layer and sintering at high temperature;

[0027] Repeat the above steps to print the upper layer until the inductance of the thick film coil is greater than 120uH, and the Q value of the thick film coil is greater than 6.

[0028] In this embodiment, the thick-film coil is formed by laminating multiple layers of printed and insulated layers, that is, several layers of silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com