Light guide plate for advertisement light box and manufacturing method of light guide plate

A technology for advertising light boxes and manufacturing methods, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of expensive manufacturing costs, low uniformity, and high cost of abrasive tools, and achieve reduction of light pollution emissions. The method is simple and easy, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

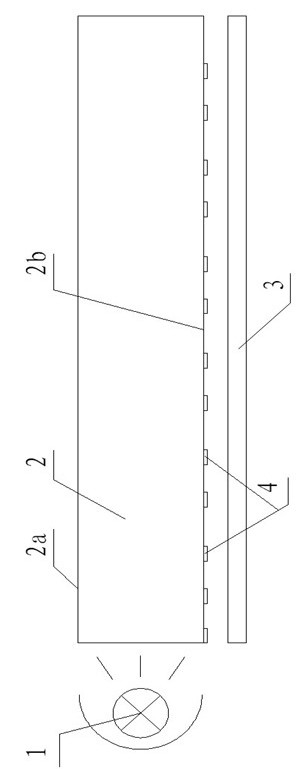

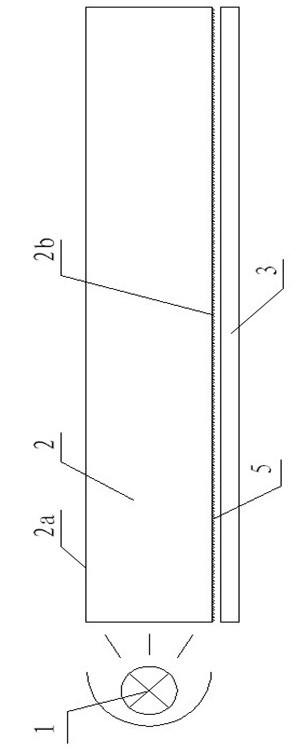

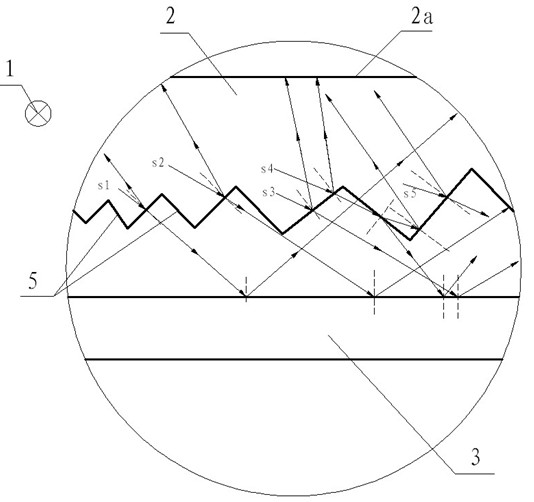

[0038] Example 1 as figure 1 , figure 2 and image 3 As shown, the light guide plate for advertising light boxes of the present invention includes a light source 1, a light-transmitting plate 2 and a reflector 3, the reflector 3 is located below the bottom surface 2b of the light-transmitting plate 2, and the light source 1 is located at the bottom of the light-transmitting plate 2 On the side, the bottom surface 2b of the transparent plate 2 is provided with a plurality of concave, linear reflective grooves 5, the reflective grooves 5 are regularly distributed on the bottom surface 2b of the transparent plate 2, the reflective The farther the groove 5 is from the light source 1, the denser the density and the deeper the depth. The reflective groove 5 has a width ranging from 0 to 200 microns and a depth ranging from 0 to 200 microns. 5 is a V-shaped structure, and the transparent plate 2 is made of polycarbonate. Light guide plate for advertising light box of the present...

Embodiment 2

[0039] Embodiment 2 is similar to Embodiment 1, the difference is that the reflective groove 5 is an arc-shaped structure, and the light-transmitting plate 2 is made of polymethyl methacrylate, and the reflective groove 5 of the arc-shaped structure It is also possible to guide the stronger light part to the side away from the light source 1 through the reflection and refraction of the light, so that the light of the entire light guide plate is uniform, and the light effect is better and the brightness is brighter. The thickness of the light guide plate for the advertising light box can be It is thinner, has lower cost, and consumes less energy, and the light-transmitting plate 2 is made of polymethyl methacrylate, so that the light-transmitting property of the entire light-transmitting plate 3 is better and the service life is longer.

Embodiment 3

[0040] Embodiment 3 is similar to Embodiment 1 and Embodiment 2, except that the reflective groove 5 is a trapezoidal structure, and the reflective groove 5 of the trapezoidal structure can reflect light due to its inclined structure on one or both sides. And refraction, it can also guide part of the light source from the side close to the light to the side far away from the light source, so that the light of the light guide plate for the entire advertising light box is uniform, and the light effect is better and the brightness is brighter. The thickness can be made thinner, the cost is lower, and the energy consumption is less.

[0041] The manufacturing method of the light guide plate for the advertising light box of the present invention comprises the following steps: making the body of the light-transmitting plate 2; processing the bottom surface 2b of the light-transmitting plate 2 by a mechanical drawing process, so that the bottom surface 2b of the light-transmitting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com