Optical control silicon carbide (SiC) photoconductive switch

A technology of photoconductive switch and photo-controlled silicon carbide, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] A high-performance and high-power photoconductive switch prepared by using V-doped semi-insulating 6H-SiC single crystal as the wafer material.

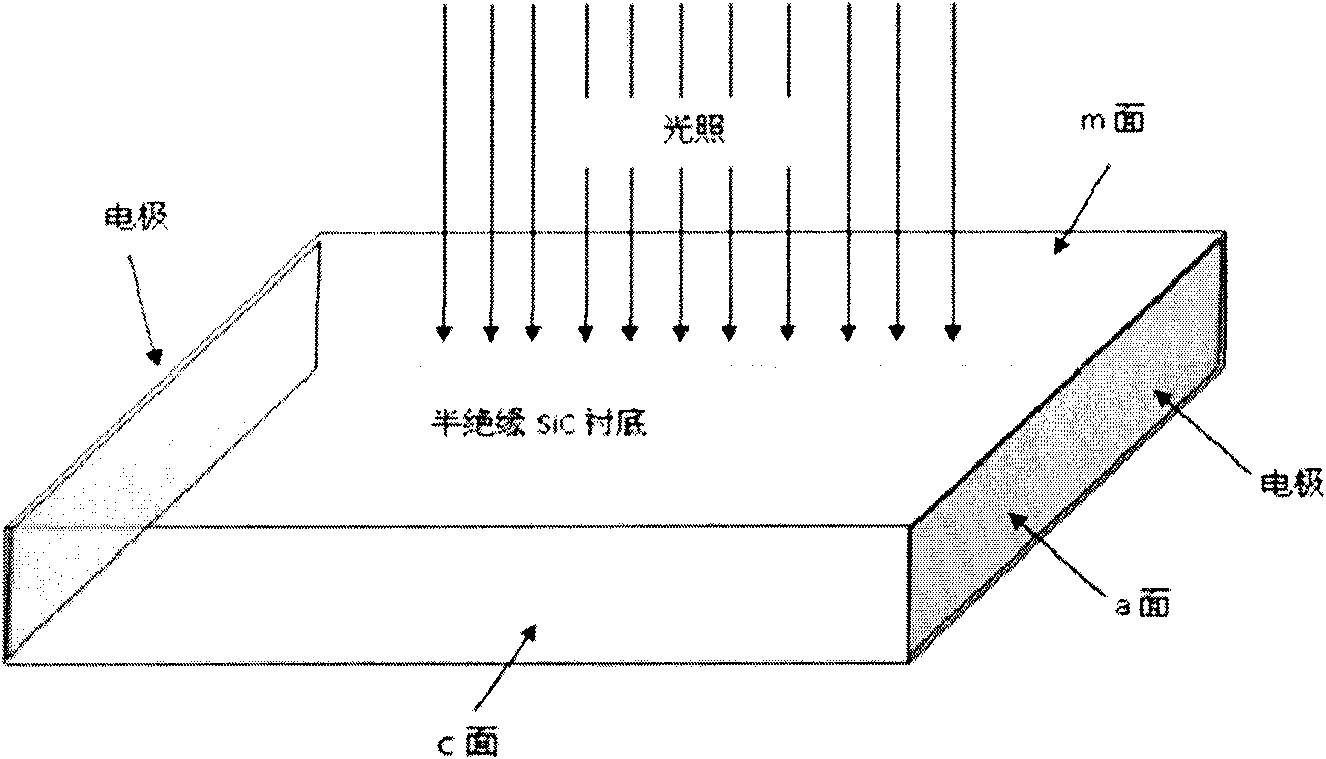

[0099] Select a V-doped semi-insulating 6H-SiC single crystal with good crystal quality ((the single crystal is grown by physical vapor transport (PVT) method, and the V doping concentration is 3.8×10 23 m -3 , the resistivity is 1.6×10 7 Ω m, the full width at half maximum of the rocking curve of the single crystal is 50 arc seconds (the parameter of crystal quality))) as the wafer material, sliced into such as image 3 The cuboid structure flake shown, where l is 12mm, d is 5mm, and h is 0.4mm.

[0100] Wherein said cuboid structure is as follows:

[0101] The light-facing surface is (1100), the four sides are (1120) and (0001) respectively, the backlight is (1100), and the deflection angle of each surface is less than 1 degree.

[0102] The m surface and a surface are polished to a roughness of less than 1nm. After cl...

Embodiment 2

[0105] A high-performance and high-power photoconductive switch prepared by using high-purity semi-insulating 6H-SiC single crystal as the wafer material.

[0106] Select a high-purity semi-insulating 6H-SiC single crystal with good crystal quality (the single crystal is grown by physical vapor transport (PVT) method, and the V doping concentration is less than 7.6×10 20 m -3 , the resistivity is 1.0×10 7 Ω m, the half-maximum width of the rocking curve of this single crystal is 45 arc seconds (the parameter of crystallization quality)) as the wafer material, sliced into such as image 3 The flakes shown, where l is 12 mm, d is 5 mm, and h is 0.5 mm. The surface m and surface a are polished to a roughness of less than 1nm, cleaned by the standard RCA process, annealed at 1200°C for 3 hours in hydrogen with a pressure of 1 bar to eliminate the surface damage layer, and then soaked in HF acid with a concentration of 10% for 12 Rinse with pure water for 30 minutes before use...

Embodiment 3

[0109] A high-performance and high-power photoconductive switch prepared by using V-doped semi-insulating 4H-SiC single crystal as the wafer material.

[0110] Select a V-doped semi-insulating 4H-SiC single crystal with good crystal quality (the single crystal is grown by physical vapor transport (PVT) method, and the V doping concentration is 6.1×10 22 m -3 , the resistivity is 3.5×10 7 Ω m, the half-maximum width of the rocking curve of this single crystal is 40 arc seconds (the parameter of crystal quality)) as the wafer material, sliced into such as image 3 The flakes shown, where l is 12 mm, d is 5 mm, and h is 0.5 mm. The surface m and surface a are polished to a roughness of less than 1nm, cleaned by the standard RCA process, annealed at 1200°C for 3 hours in hydrogen with a pressure of 1 bar to eliminate the surface damage layer, and then soaked in HF acid with a concentration of 10% for 12 Rinse with pure water for 30 minutes before use, cover the mask, put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com