Innocent treatment method of electrolytic manganese slag

A technology for harmless treatment and electrolysis of manganese slag, applied in the field of resource recycling, can solve the problems of few practical applications in enterprises and society, limited market capacity, difficult to promote and apply, etc., to achieve automatic catalytic oxidation, employment promotion, pharmaceutical source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

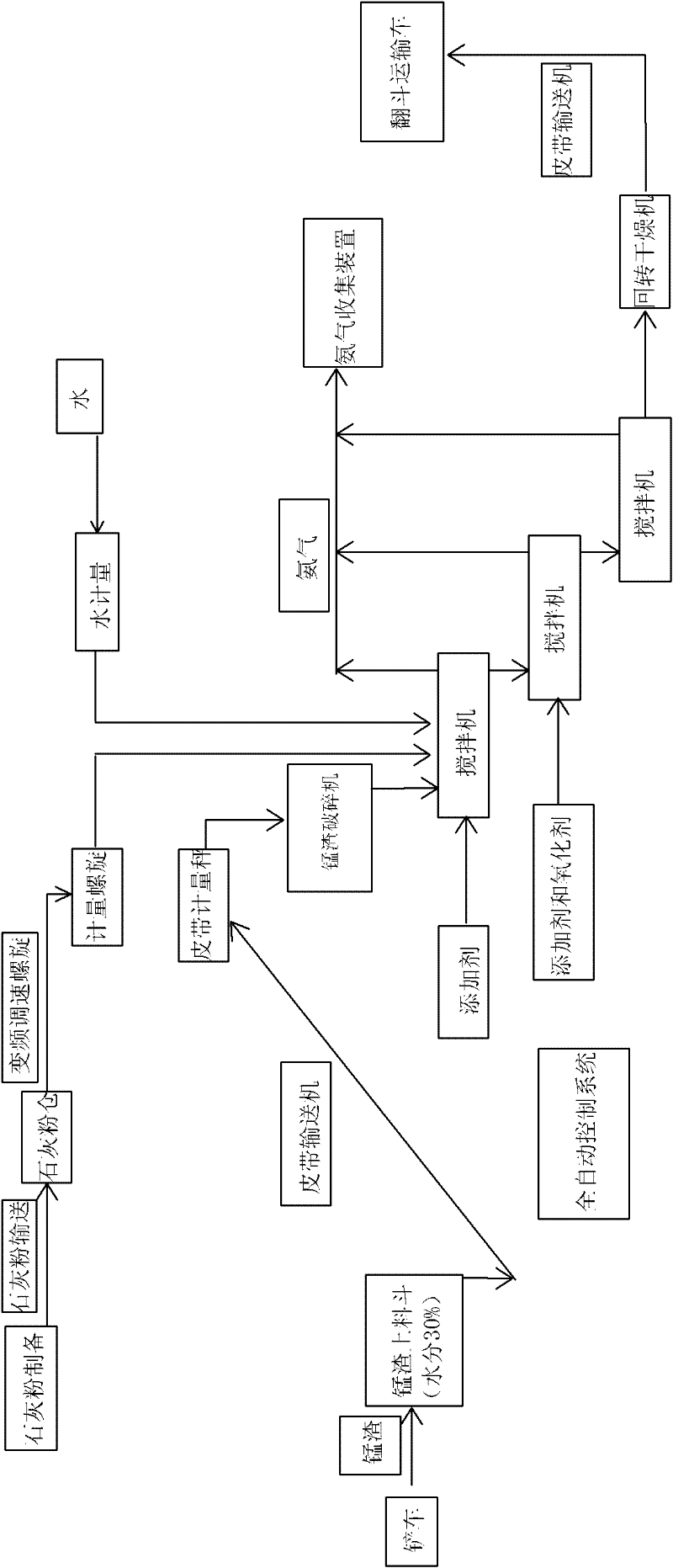

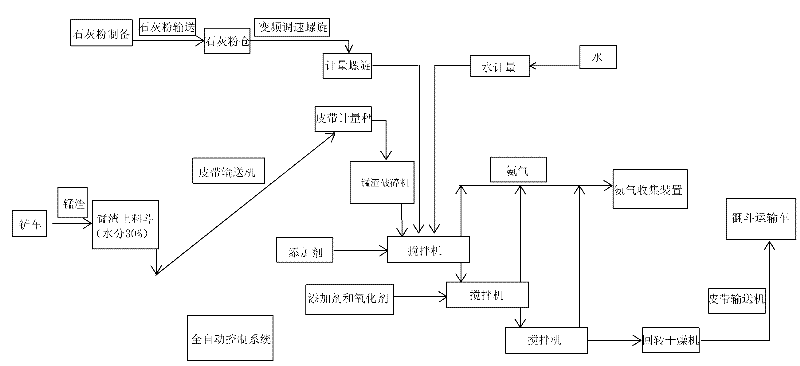

Image

Examples

Embodiment 1

[0028] (1) Accurately weigh 80 parts by weight of manganese slag through the metering equipment and transport it to the manganese slag crusher for crushing; then transport it to the mixer through the feeding device.

[0029] (2) While stirring, add 7 parts by weight of quicklime powder to the mixer, add 8.7 parts by weight of water at a temperature of 20°C, and 1.3 parts by weight of sodium silicate, and stir in the mixer for 3 minutes before unloading ;

[0030] (3) Transfer the electrolytic manganese slag mixture through a stirring process to another mixer, add 1 weight part of sodium lignosulfonate and 2 weight parts of ferric chloride therein, carry out secondary stirring and mix uniformly;

[0031] (4) Transport the mixture processed by the second stirring to the third mixer, fully stir evenly, and make the reaction fully.

[0032] (5) After three times of stirring, the mixed material is unloaded into a rotary dryer for drying, and the moisture content of the mixed mater...

Embodiment 2

[0036](1) Accurately weigh 77.4 parts by weight of manganese slag through the metering equipment and transport it to the manganese slag crusher for crushing; then transport it to the mixer through the feeding device.

[0037] (2) While stirring, add 9.6 parts by weight of quicklime powder to the mixer, add 8.7 parts by weight of water at a temperature of 20°C, and 1.3 parts by weight of sodium silicate, stir in the mixer for 3 minutes and then unload ;

[0038] (3) Transfer the mixed material through a stirring process to another mixer, add 1 weight part of sodium lignosulfonate and 2 weight parts of ferric chloride therein, carry out secondary stirring and mix uniformly;

[0039] (4) Transport the mixture processed by the second stirring to the third mixer, fully stir evenly, and make the reaction fully.

[0040] (5) Transfer the unloading of the mixed material after three stirring treatments to a rotary dryer for drying, and control the moisture content of the mixed materia...

Embodiment 3

[0044] (1) Accurately weigh 74 parts by weight of manganese slag through the metering equipment and transport it to the manganese slag crusher for crushing; then transport it to the mixer through the feeding device.

[0045] (2) In the stirring state, add 13 parts by weight of quicklime powder to the mixer, add 8.7 parts by weight of water at a temperature of 20 ° C, and 1.3 parts by weight of sodium silicate, stir in the mixer for 3 minutes and then unload ;

[0046] (3) Transfer the mixture after the primary stirring process to another mixer, add 1 weight part of sodium lignosulfonate and 2 weight parts of ferric chloride therein, carry out secondary stirring and mix uniformly;

[0047] (4) Transport the mixture processed by the second stirring to the third mixer, fully stir evenly, and make the reaction fully.

[0048] (5) Transfer the unloading of the mixed material after three stirring treatments to a rotary dryer for drying, and control the moisture content of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com