Vacuum distillation process for extracting silver from silver zinc slag

A technology of distillation extraction and silver-zinc slag, which is applied in the field of metal smelting, can solve the problems of long extraction process, loss of recovery rate, environmental pollution, etc., and achieve the effect of simple process, low cost and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

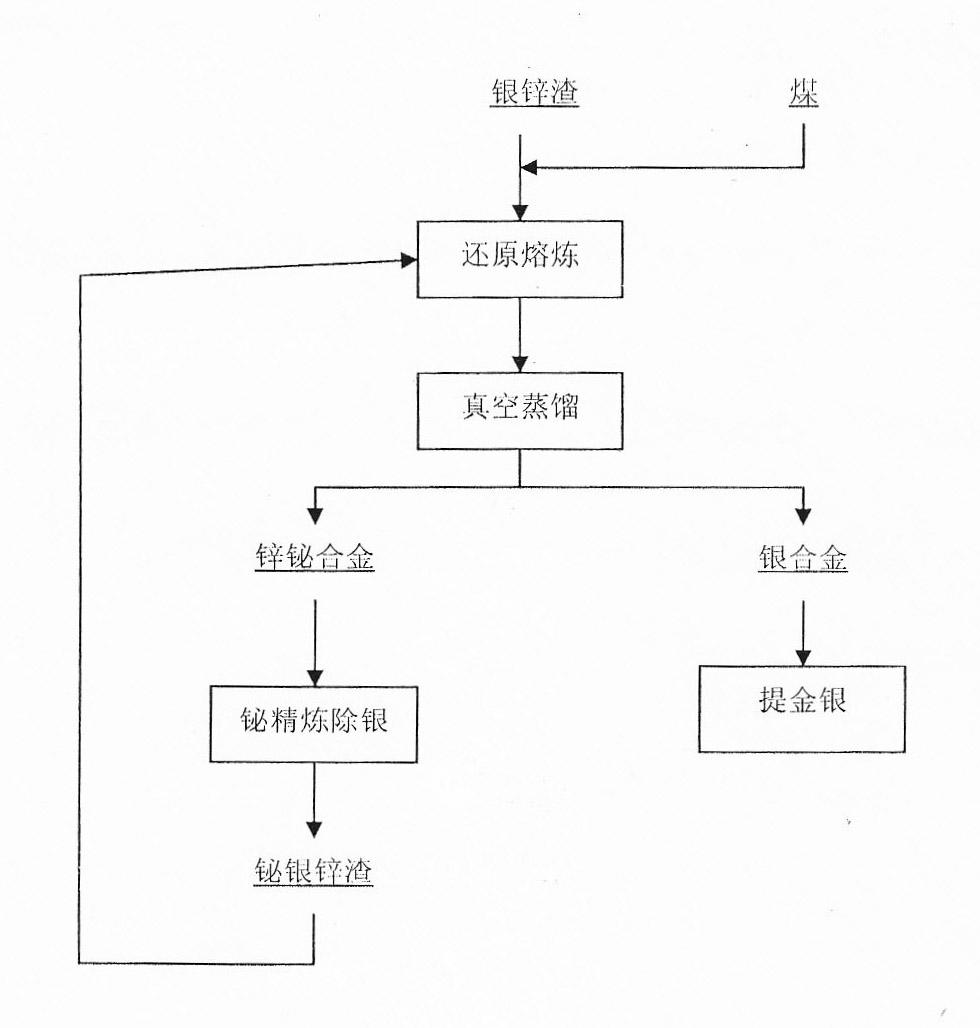

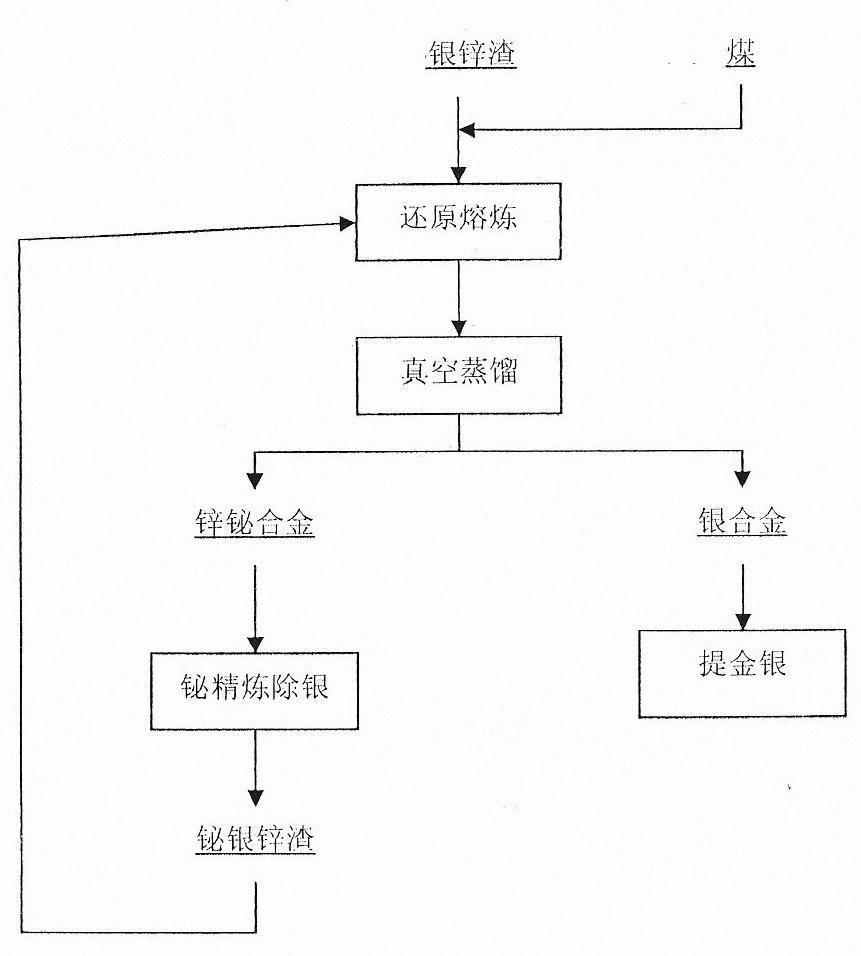

[0011] Taking 1000kg of silver-zinc slag as raw material to extract pure silver as an example:

[0012] 1. Put 1000kg of silver-zinc slag in a vacuum distillation furnace, add 50kg of reducing agent coal, and carry out reduction smelting at a temperature of 1000°C to 1200°C to obtain a silver-zinc-bismuth alloy.

[0013] 2. The silver-zinc-bismuth alloy obtained above is vacuum distilled in a vacuum distillation furnace under a vacuum state of 20 to 100 Pa to produce 50 kg of silver alloy with a silver content of more than 98% and 950 kg of zinc-bismuth alloy.

[0014] 3. Refining the silver alloy produced above to obtain 49 kg of pure silver.

[0015] 4. The zinc-bismuth alloy produced by vacuum distillation is directly used in the process of bismuth refining, adding zinc and removing silver, and the produced bismuth-silver-zinc slag is returned for reduction smelting and vacuum distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com