Method for increasing performance parameter of quantum dot sensitized solar battery

A technology for sensitizing solar cells and quantum dots, which is applied in the field of solar cells to achieve the effects of improving short-circuit current and photoelectric conversion efficiency, suppressing the generation of dark current, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific steps of a method for improving performance parameters of quantum dot-sensitized solar cells are:

[0024] 1) Grind 0.2g of P25 titanium dioxide and a binder to make a slurry, print it on conductive glass by screen printing, and bake it at 500°C for 4h to obtain the electrode material to be sensitized, and the film of the electrode material The thickness is 5 μm;

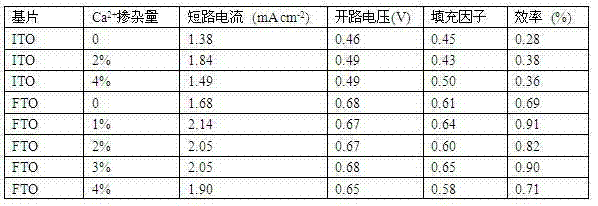

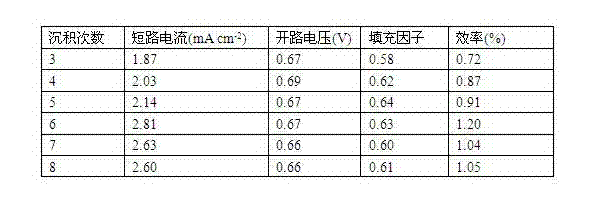

[0025] 2) Alternately immerse the electrode material to be sensitized in 0.1M Cd(NO 3 ) 2 ethanol solution to neutralize 0.1M Na 2 In the aqueous solution of S, where Cd(NO 3 ) 2 The ethanol solution contained 0.2% Ca(NO 3 ) 2 , to be Ca 2+ When the mass molar concentration on the electrode material is between 1%, it becomes a sensitized electrode material;

[0026] 3) Assemble the sensitized electrode material, the Pt counter electrode and the injected liquid electrolyte solution to form the quantum dot sensitized solar cell with a sandwich structure.

[0027] The binder in step 1) is a...

Embodiment 2

[0029] The specific steps of a method for improving performance parameters of quantum dot-sensitized solar cells are:

[0030] 1) Grind 2g of P25 titanium dioxide and a binder to make a slurry, print it on conductive glass by screen printing, and bake it at 550°C for 1h to obtain the electrode material to be sensitized. The film thickness of the electrode material is 15 μm;

[0031] 2) Alternately immerse the electrode material to be sensitized in 1M Cd(NO 3 ) 2 Ethanol solution neutralizes 1M Na 2 In the aqueous solution of S, where Cd(NO 3 ) 2 The ethanol solution contained 8% Ca(NO 3 ) 2 , to be Ca 2+ When the mass molar concentration on the electrode material is between 5%, it becomes a sensitized electrode material;

[0032] 3) Assemble the sensitized electrode material, the Pt counter electrode and the injected liquid electrolyte solution to form the quantum dot sensitized solar cell with a sandwich structure.

[0033] The binder in step 1) is an ethanol solutio...

Embodiment 3

[0035] The specific steps of a method for improving performance parameters of quantum dot-sensitized solar cells are:

[0036] 1) Grind 1g of P25 titanium dioxide and a binder to make a slurry, print it on conductive glass by screen printing, and bake it at 520°C for 3h to obtain the electrode material to be sensitized. The film thickness of the electrode material is 10μm;

[0037] 2) Alternately immerse the electrode material to be sensitized in 0.5M Cd(NO 3 ) 2 ethanol solution to neutralize 0.5M Na 2 In the aqueous solution of S, where Cd(NO 3 ) 2 The ethanol solution contained 5% Ca(NO 3 ) 2 , to be Ca 2+ When the mass molar concentration on the electrode material is between 3%, it becomes a sensitized electrode material;

[0038] 3) Assemble the sensitized electrode material, the Pt counter electrode and the injected liquid electrolyte solution to form the quantum dot sensitized solar cell with a sandwich structure.

[0039] The binder in step 1) is an ethanol so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com