Drug sustained release agent, adsorbent, functional food, mask, and adsorptive sheet

A technology of adsorbents and sustained-release agents, which is applied in the fields of drug sustained-release agents, adsorbents, functional foods, masks and absorbent sheets, and can solve the problems of patients with large physical and mental burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

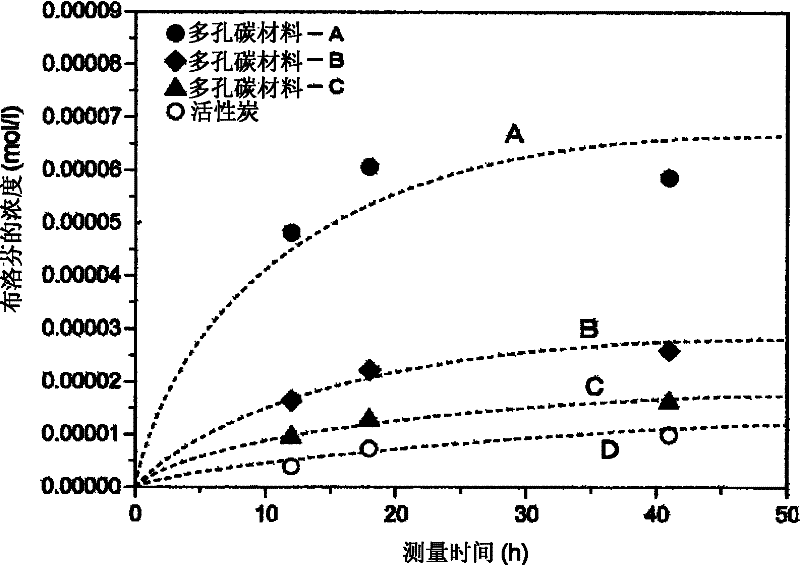

[0067] Example 1 relates to the drug sustained-release preparations according to the first to third embodiments of the present invention. In Example 1, first, a porous carbon material was produced based on the method described below.

[0068] Using monodisperse spherical particles of silica (trade name: SEAHOSTAR KE) manufactured by Nippon Shokubai Co., Ltd. or spherical particles of silica (trade name: SNOWTEX) manufactured by Nissan Chemical Industries, Ltd., prepared with a solid content Aqueous monodisperse silica colloidal suspensions in aqueous solutions having a concentration of 3 to 40 wt %. Incidentally, the diameter of the colloidal particles is in the range of 6 nm to 1 μm. The monodisperse silica colloidal suspension aqueous solution was poured into an SPC filter holder (manufactured by Shibata Scientific Technology Ltd.) having a diameter of 30 mm in which a filter cloth was placed, and suction filtration under vacuum was performed using an aspirator . Incident...

Embodiment 2

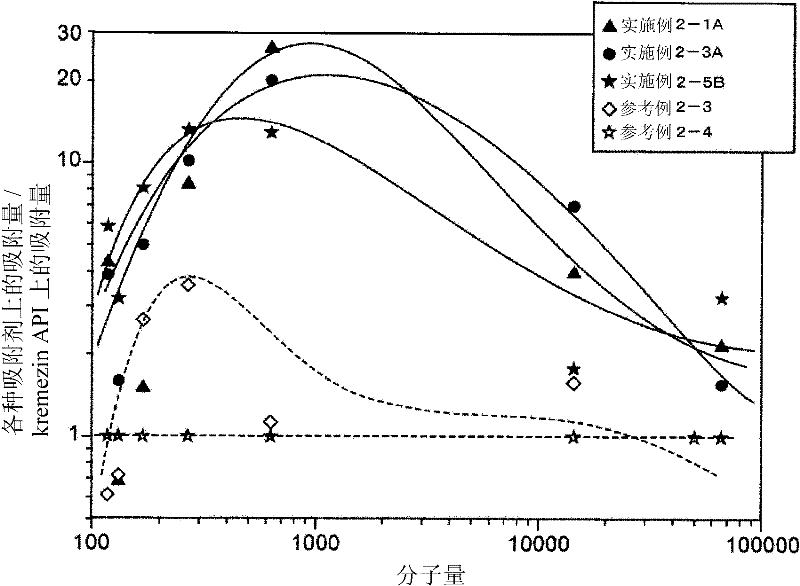

[0081] Example 2 relates to the adsorbents for adsorbing organic substances thereon according to the first to third embodiments of the present invention, the adsorbents for medical use according to the first to third embodiments of the present invention, and the adsorbents according to the present invention The adsorbent for oral administration of the first to third embodiments. In Example 2, porous carbon material D, porous carbon material E, porous carbon material F, porous carbon material G, and porous carbon material H were produced based on the same method as described in Example 1. Incidentally, the porous carbon material D, the porous carbon material E, and the porous carbon material F were subjected to nitric acid treatment as a chemical treatment, while the porous carbon material F and the porous carbon material G were subjected to activation treatment by using water vapor. Table 1 lists the carbonization temperature, the presence or absence of nitric acid treatment, ...

Embodiment 3

[0159] Example 3 relates to adsorbents for adsorbing allergens thereon according to the first to third embodiments of the present invention. In Example 3, the samples of Examples 2-3B were used as porous carbon materials (see Table 1). In addition to this, as a reference example, the sample of Reference Example 2-1 was used (see Table 2). For the samples of Example 2-3B and Reference Example 2-1, the allergen (Der p 1) caused by the mite and the allergen caused by the pollen of Japanese cedar (Cry j 1) per gram of the sample were measured adsorption capacity. The measurement of the adsorption amount was basically carried out by the same method as in Example 2. Der p 1 has a molecular weight of 36,000 to 40,000, while Cry j 1 has a molecular weight of 50,000. The adsorption amount on the sample of Example 2-3B in the case where the adsorption amount on the sample of Reference Example 2-1 is regarded as "1" is shown in Table 21 below. Therefore, it can be seen that the adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com