Super-hydrophobic silicon micron-nano composite structure and preparation method thereof

A composite structure and super-hydrophobic technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of uncontrollable morphology of silicon micro-nano composite structures, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

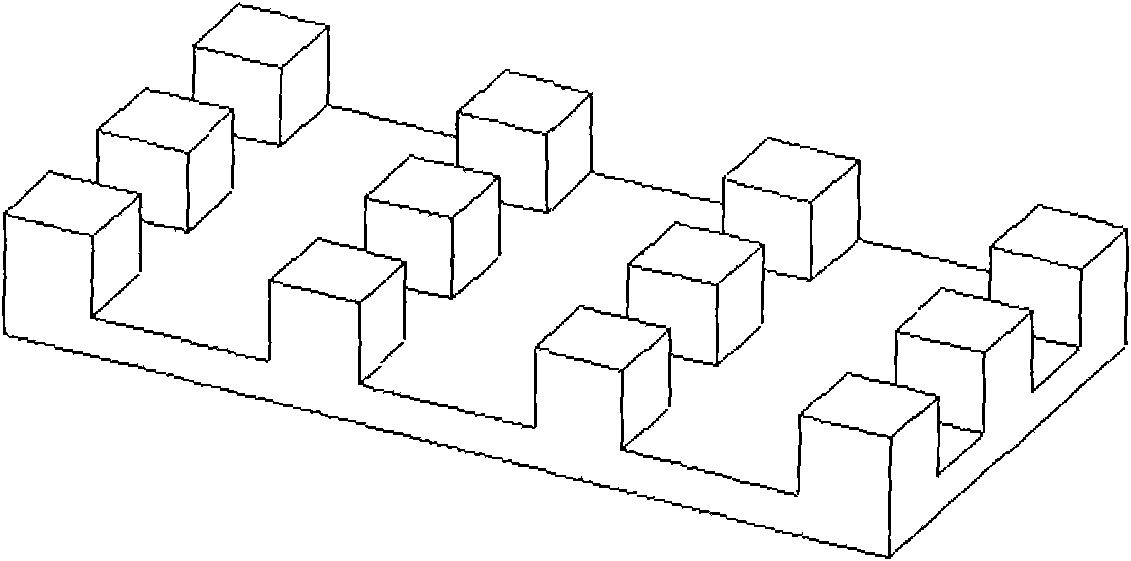

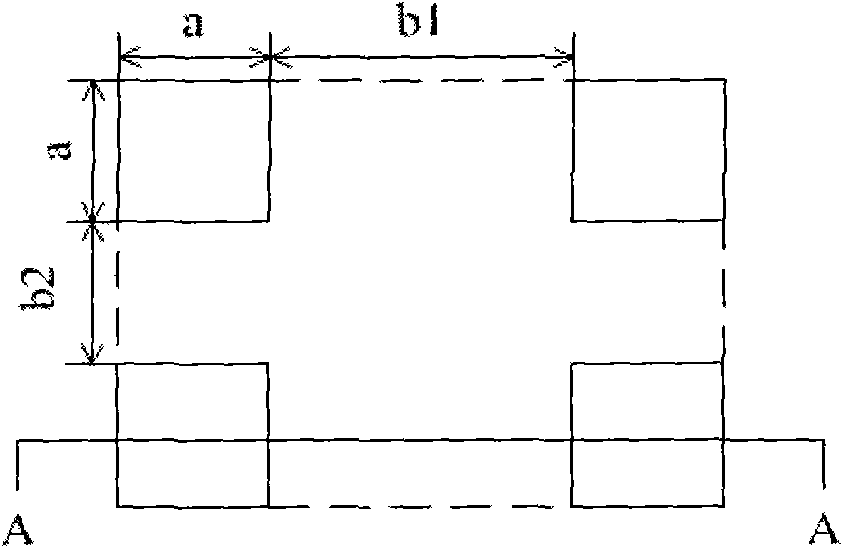

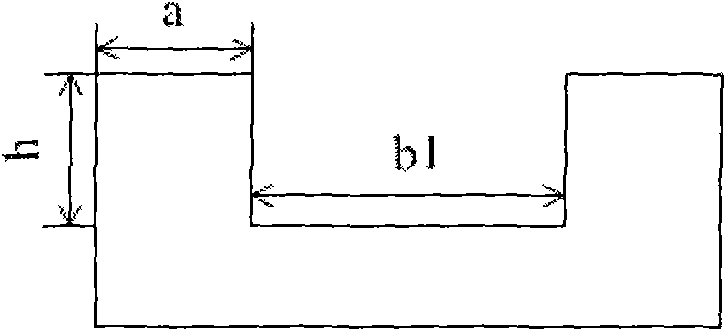

[0032] The super-hydrophobic silicon micro-nano composite structure in this embodiment is: a super-hydrophobic silicon micro-nano composite structure with 100×100 square column array micron structures on the silicon surface, each micron structure having a side length a=20 μm and a height h= 20 μm, the horizontal distance between two adjacent microstructures is b1=40 μm, the vertical distance is b2=80 μm, and there are columnar nanostructures on the surface of each microstructure.

[0033] The method for preparing a silicon superhydrophobic micro-nano composite structure in this embodiment includes the following steps:

[0034] Step 1: Making a reticle: through the reticle design, the size parameters of the array micron structure are a=20μm, b1=40μm, b2=80μm;

[0035] Step 2: Photolithography: Perform photolithography through processes such as glue coating, pre-baking, exposure, development, and post-baking, and copy the mask pattern onto the photoresist on the surface of the silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com