Retardant plasticizer methyl silicate ester compound and preparation method thereof

A technology of flame retardant plasticizer and methyl silicate tri-ester, which is applied in the field of methyl silicate triester compound and its preparation, can solve the problems of limited development and application, high price of silicon-based flame retardant plasticizer, etc., and achieve cost Low cost, easy large-scale production, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

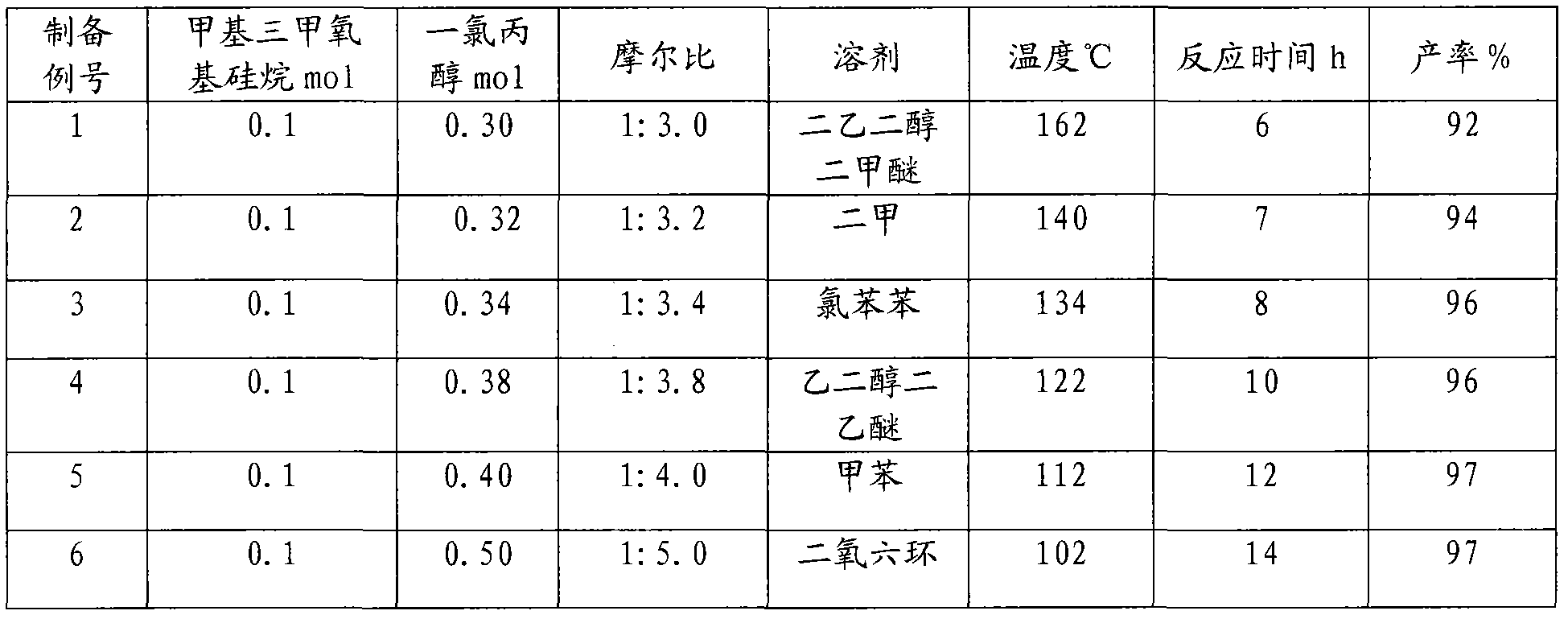

Embodiment 1

[0028] Example 1 In a 200ml four-neck flask equipped with a stirrer, a thermometer and a fractional distillation device, add 0.1mol (13.6g) of methyltrimethoxysilane and 0.3mol (28.4g) of monochloropropanol and 45ml of diethylene glycol Dimethyl ether, make it warm up to 104 ℃ and reflux, and continuously distill the methanol generated by the reaction through the fractionation device (control the column top temperature not higher than 64 ℃). As the reaction progresses, the reflux temperature gradually increases to 162 ℃, and the The time is about 6h, until the methanol evaporated is close to the theoretical amount. Then distill off the solvent, excess dichloropropanol (recovered for use) and low boilers, and cool to obtain tris(monochloropropyl)methylsilicate with a yield of 92%. Its flash point (open cup): 200±5°C, decomposition temperature: 250±5°C, density 1.273g / ml, refractive index n D 25 = 1.4486.

Embodiment 2

[0029] Example 2 In a 200ml four-necked flask equipped with a stirrer, a thermometer and a fractionation device, add 0.1mol (13.6g) methyltrimethoxysilane and 0.32mol (30.3g) monochloropropanol and 45ml xylene to make It was heated to reflux at 104°C, and the methanol produced by the reaction was continuously distilled through the fractionation device (controlling the column top temperature not higher than 64°C). The distilled methanol is close to the theoretical amount. Then distill off the solvent, excess dichloropropanol (recovered for use) and low boilers, and cool to obtain tris(monochloropropyl)methylsilicate with a yield of 94%. Its flash point (open cup): 200±5°C, decomposition temperature: 250±5°C, density 1.273g / ml, refractive index n D 25 = 1.4486.

Embodiment 3

[0030] Example 3 In a 200ml four-necked flask equipped with a stirrer, a thermometer and a fractional distillation device, add 0.1mol (13.6g) methyltrimethoxysilane and 0.34mol (32.2g) monochloropropanol and 45ml chlorobenzene to make It was heated to reflux at 104°C, and the methanol produced by the reaction was continuously distilled out through the fractionation device (controlling the column top temperature not higher than 64°C). The distilled methanol is close to the theoretical amount. Then distill off the solvent, excess dichloropropanol (recovered for use) and low boilers, and cool to obtain tris(monochloropropyl)methylsilicate with a yield of 96%. Its flash point (open cup): 200±5°C, decomposition temperature: 250±5°C, density 1.273g / ml, refractive index n D 25 = 1.4486.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com