Methyl tri(2-chloroethoxy) silane compound and preparation method thereof

A technology of chloroethoxyl and methyl trisilane, which is applied in the field of methyltrisilane compound and its preparation, can solve the problems of expensive silicon-based flame-retardant plasticizers, development and application limitations, etc., and achieve easy scale production and low cost. Low, good flame retardancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

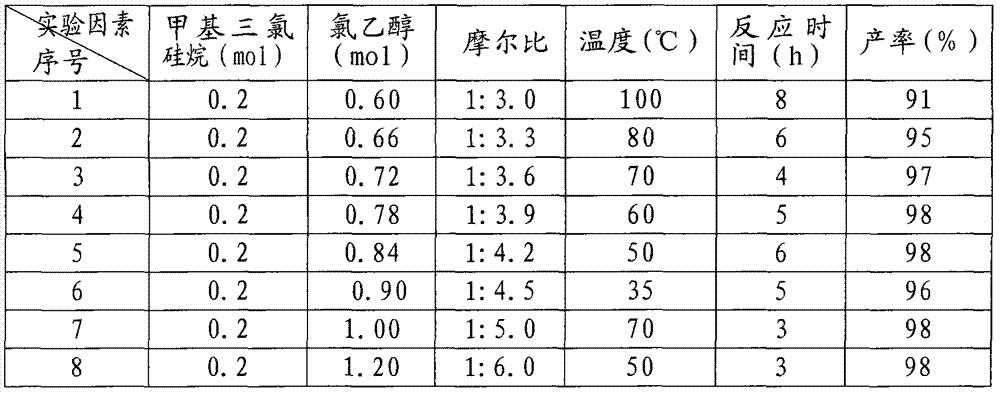

Embodiment 1

[0017] Example 1 In a 200ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device on the mouth of the condenser, add 0.2mol (29.9g) methyltrichlorosilane, Then add 0.6mol (48.3g) of chloroethanol dropwise under the condition of cooling in a water bath, and control the temperature at a rate of addition not to exceed 35°C. After the drop is completed, the temperature is raised to 100°C and the reaction is refluxed for 8 hours. After the melamine is stirred evenly, a small amount of low boiling point matter is removed by distillation under reduced pressure, cooled and filtered to obtain a colorless liquid methyl tris(2-chloroethoxy)silane, and the product yield is 91%. Its decomposition temperature is 235±5°C, and its flash point (open cup) is 195±5°C. Density is 1.333 (20°C), refractive index n D 25 = 1.4558.

Embodiment 2

[0018] Example 2 In a 200ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device at the mouth of the condenser, add 0.2mol (29.9g) methyltrichlorosilane, Then add 0.66mol (53.1g) of chloroethanol dropwise under the condition of water bath cooling, and control the temperature not to exceed 35°C with the rate of addition. Melamine, after stirring, remove excessive chlorohydrin (recycling) and a small amount of low boiling point by distillation under reduced pressure, cool and filter to obtain colorless liquid methyl tris (2-chloroethoxy) silane, product yield 95% . Its decomposition temperature is 235±5°C, and its flash point (open cup) is 195±5°C. Density is 1.333 (20°C), refractive index n D 25 = 1.4558.

Embodiment 3

[0019] Example 3 In a 200ml four-neck flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device connected to the mouth of the condenser, add 0.2mol (29.9g) methyltrichlorosilane, Then add 0.72mol (58g) of chloroethanol dropwise under the condition of cooling in a water bath, and control the temperature by the rate of addition to not exceed 35°C. After dropping, the temperature is raised to 70°C for reflux for 4 hours. After the hydrogen chloride is released, the reaction is completed, and 1.0g of melamine is added After stirring evenly, excessive chloroethanol (recycled) and a small amount of low boiling point were removed by distillation under reduced pressure, cooled and filtered to obtain a colorless liquid methyl tris (2-chloroethoxy) silane, and the product yield was 97%. Its decomposition temperature is 235±5°C, and its flash point (open cup) is 195±5°C. Density is 1.333 (20°C), refractive index n D 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com