Winder special for nickel zinc battery

A nickel-zinc battery and winding machine technology, applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems such as the inability to guarantee the quality of the battery cell, aggravating the short circuit in the middle of the battery, and the easy slippage and deformation of the diaphragm. , to achieve the effect of simple structure, reducing short circuit and small shaft runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

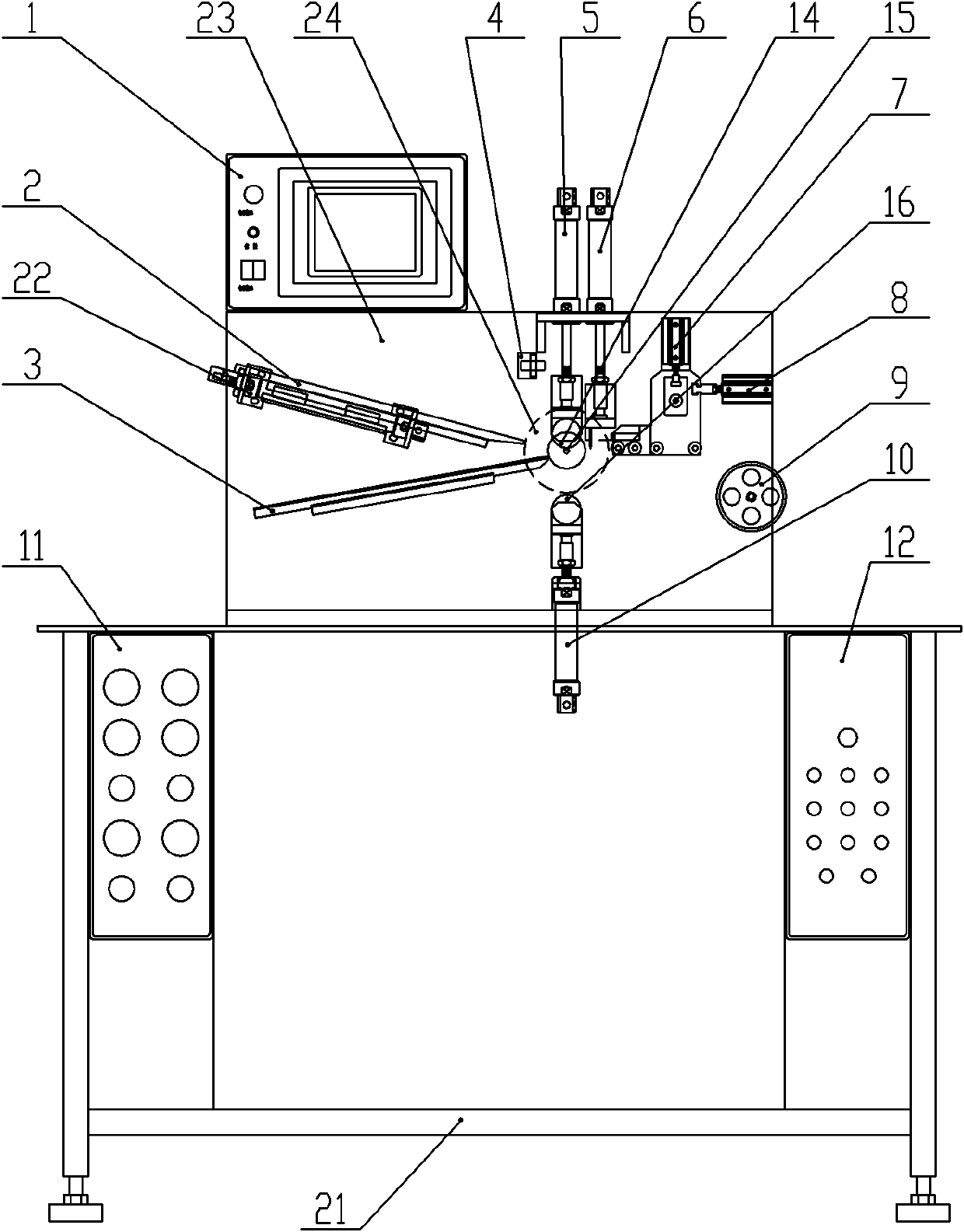

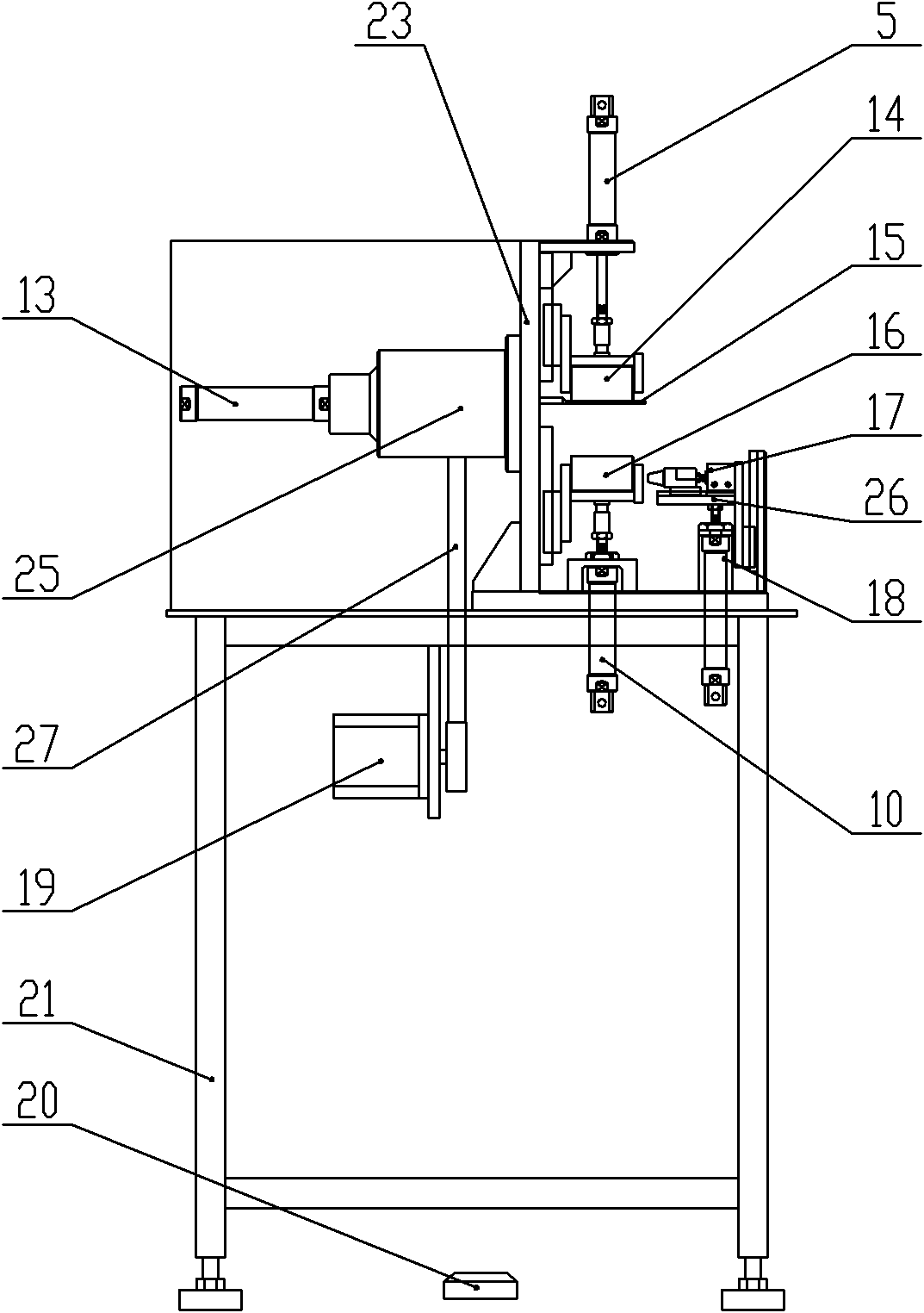

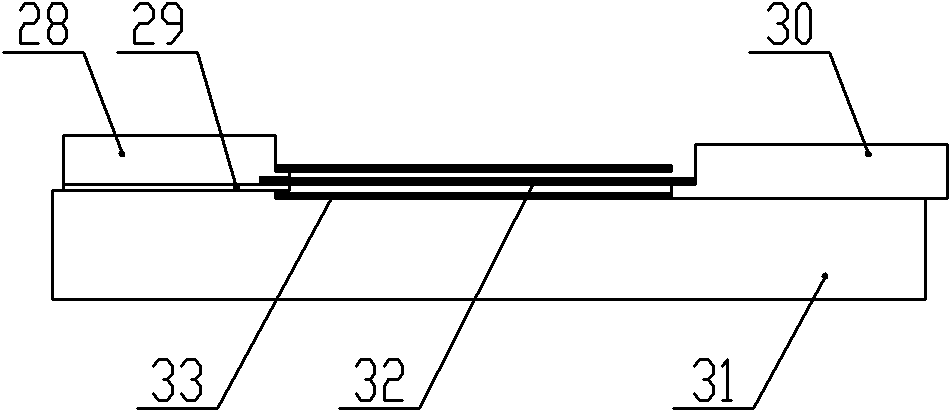

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Figure 1~Figure 4 Among them, including the control touch screen 1, the positive electrode discharge plate 2, the negative electrode diaphragm discharge plate 3, the secondary air pressure sensor 4, the upper pressure roller cylinder 5, the tape cutting cylinder 6, the tape pulling cylinder 7, and the tape feeding cylinder 8 , Adhesive tape loader 9, lower pressure roller cylinder 10, air circuit control panel 11, work reminder light panel 12, needle extraction cylinder 13, upper pressure roller 14, winding needle 15, lower pressure roller 16, positioning cylinder 17, positioning Platform lifting cylinder 18, stepping motor 19, pedal 20, base 21, slideway 22, vertical plate 23, battery core 24, winding needle seat 25, positioning platform 26, belt 27, reference plate 28, partition Plate 29, limiting plate 30, supporting plate 31, ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com