Method for operating an internal combustion engine

一种内燃机、燃料消耗的技术,应用在内燃活塞发动机、燃烧发动机、机械设备等方向,能够解决小喷射时间、气态排出体积流量不可控制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

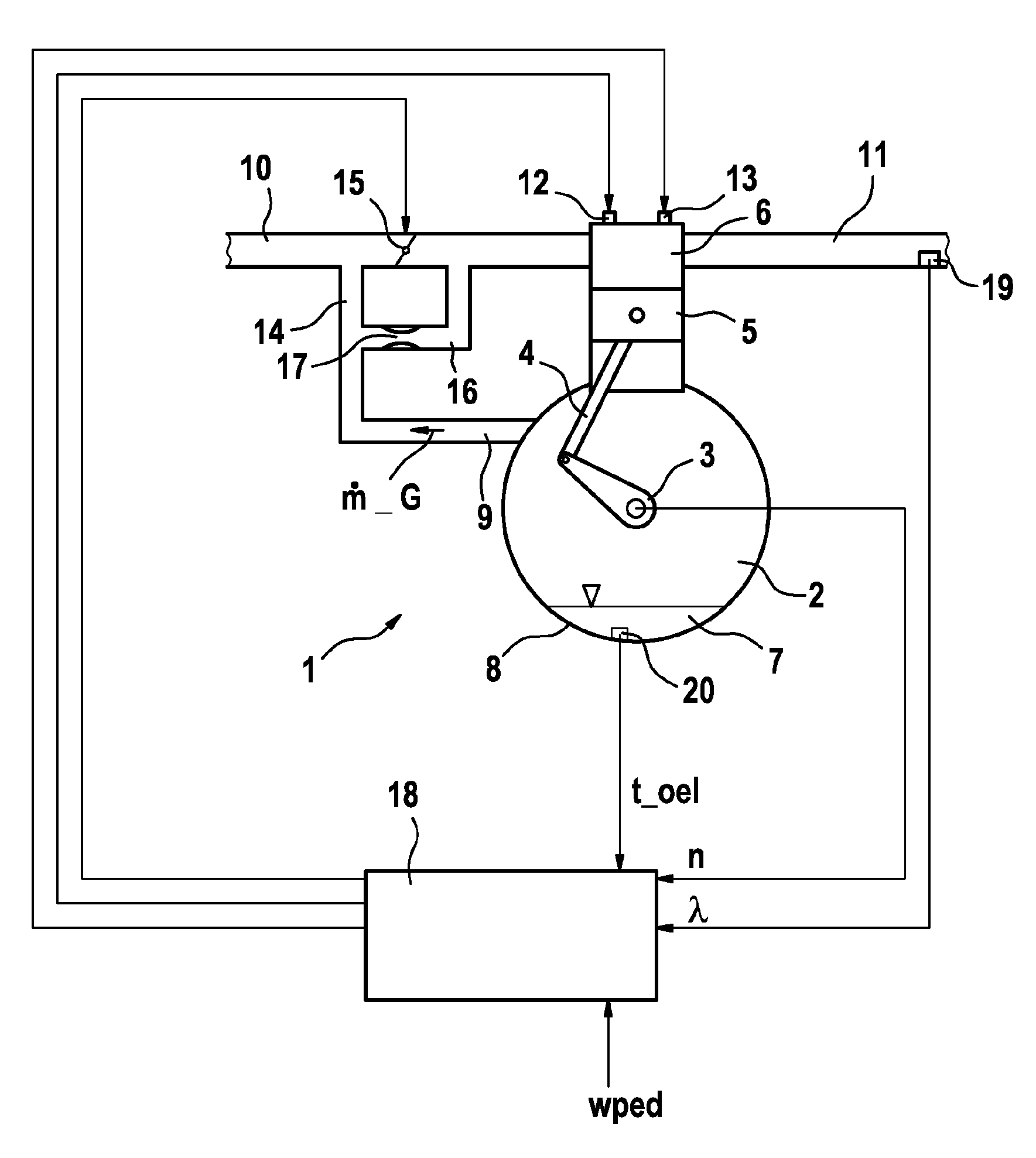

[0021] figure 1 A schematic diagram of an internal combustion engine 1 with a crankcase 2 in which a crankshaft 3 is arranged is shown. The crankshaft 3 is connected with the piston 5 through the connecting rod 4, and the piston 5 is arranged on the cylinder 6 in a manner capable of moving back and forth. For the sake of simplicity, only one cylinder of an internal combustion engine is shown here, usually an internal combustion engine has multiple cylinders, eg 4 or 6 cylinders. Engine oil 7 is located in the crankcase 2 , which is delivered to the corresponding lubrication points, in particular also to the running surfaces of the piston 5 in the cylinder 6 , via lines and pumps not shown here. Engine oil accumulates in the oil pan 8 . In order to reduce the excess pressure in the piston box 2 , the piston box 2 is connected by an exhaust line 9 to an intake system 10 of the internal combustion engine. Ambient air is sucked into the cylinder 6 via an intake system 10 in a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com