Technique for purifying heavy oil-contaminated soil by acoustochemical method

A sonochemical and polluted soil technology, applied in the restoration of polluted soil, etc., can solve the problems of being vulnerable to harsh environmental impact, limited repair effect, short treatment cycle, etc., and achieves the effects of environmental friendliness, easy recycling, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

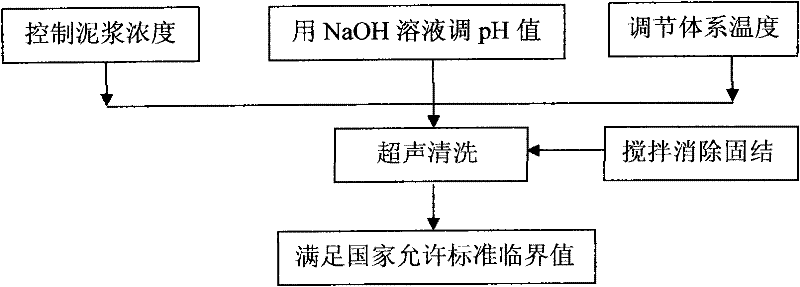

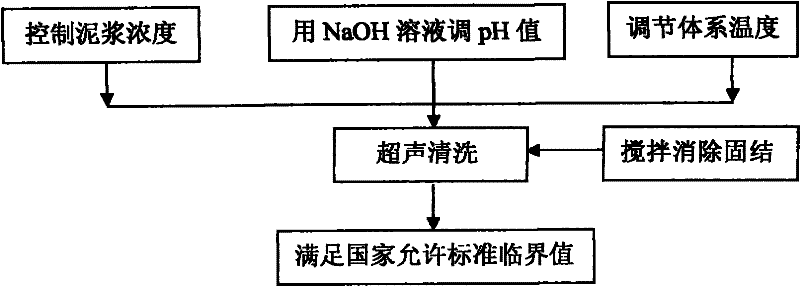

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode 1: A sonochemical method for purifying heavy oil-contaminated soil technology. After mixing the soil sample with deionized water, it is prepared into a slurry with a liquid-solid mass ratio of 4:1, and Na is added to the slurry. 2 CO 3 And control its mass content to 0.10%, add NaOH solution to adjust the pH value to 8, and use ultrasonic wave to clean the mud for 5 minutes at the treatment temperature of 25°C, and the ultrasonic frequency is set to 48KHz.

specific Embodiment approach 2

[0015] Specific implementation mode two: a sonochemical method for purifying heavy oil-contaminated soil technology, mixing soil samples with deionized water to prepare mud with a liquid-solid mass ratio of 6:1, and adding Na to the mud 2 CO 3 And control its mass content to 0.13%, add NaOH solution to adjust the pH value to 8.5, and use ultrasonic wave to clean the mud for 10 minutes at the treatment temperature of 18°C, and the ultrasonic frequency is set to 55KHz.

specific Embodiment approach 3

[0016] Specific implementation mode three: a sonochemical method for purifying heavy oil-contaminated soil technology, mixing soil samples with deionized water to prepare mud with a liquid-solid mass ratio of 8:1, and adding Na to the mud 2 CO 3 And control its mass content to 0.15%, add NaOH solution to adjust the pH value to 9, and use ultrasonic wave to clean the mud for 14min at the treatment temperature of 20°C, and the ultrasonic frequency is set to 63KHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com