Preparation method of anatase-type nanomaterial and self-cleaning solar glass made from nanomaterial

A technology of solar glass and nanomaterials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of not being able to form a self-cleaning layer on the glass surface, achieve the effects of slowing down the anti-ultraviolet function, low cost, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

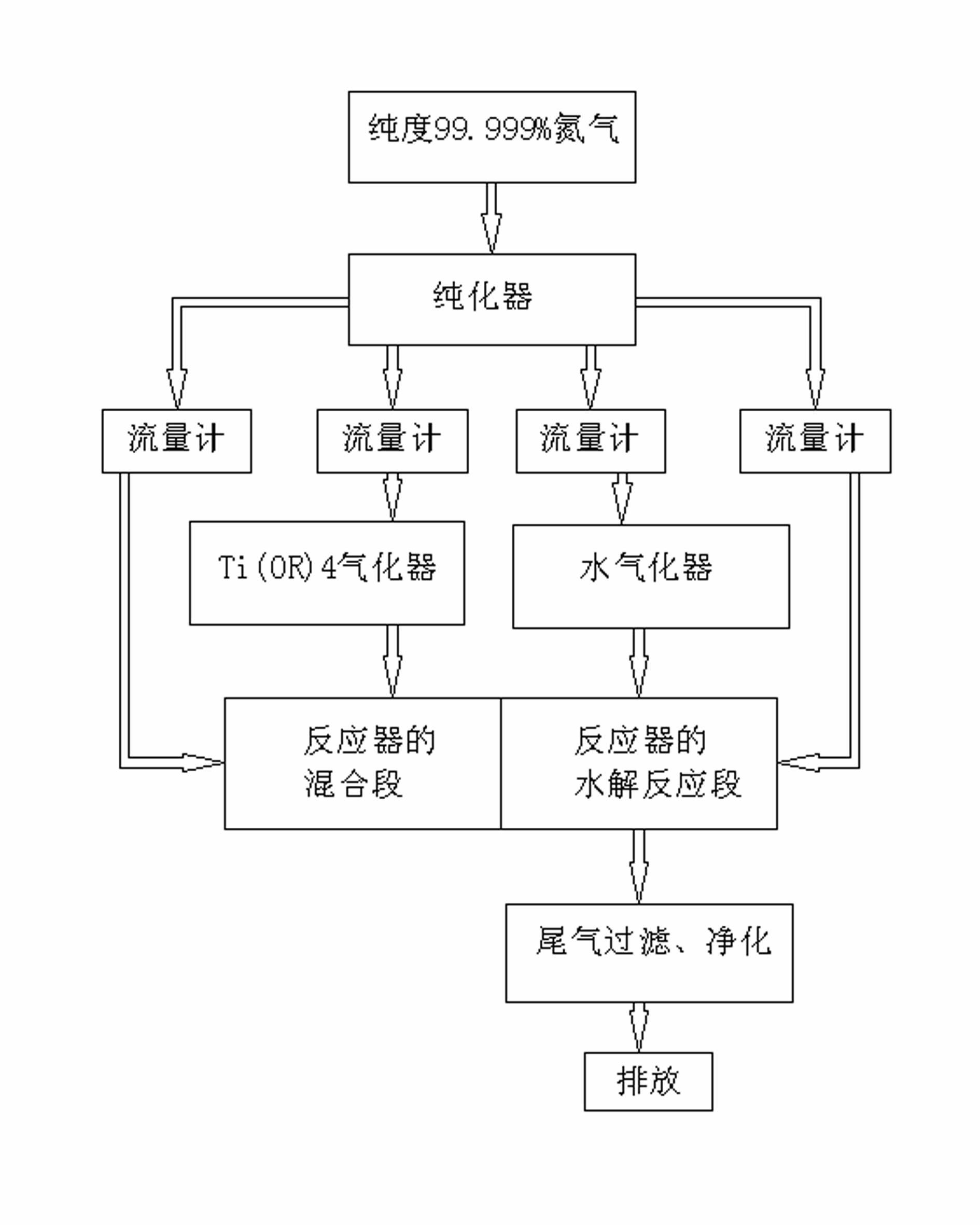

[0018] Referring to accompanying drawing, this method is realized by the gas-phase hydrolysis method of titanium alkoxide: this method is realized by the following steps:

[0019] (1) High-purity nitrogen with a content of 99.999% is divided into four routes, the first nitrogen enters Ti(OR) 4 Vaporizer, carrying Ti(OR) 4 The steam enters the mixing section of the reactor, the second nitrogen enters the water vaporizer, and the water vapor is brought into the hydrolysis reaction section of the reactor, the third nitrogen enters the mixing section of the reactor, and the third nitrogen enters the hydrolysis reaction section of the reactor reaction section.

[0020] ⑵ Carrying Ti(OR) in the mixing section of the reactor 4 Steam nitrogen is mixed with cold nitrogen to form Ti(OR) 4 Aerosol particles, Ti(OR) formed 4 The aerosol particles enter the hydrolysis reaction section of the reactor, and the Ti(OR) in the hydrolysis reaction section of the reactor 4 Production of TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com