Slow-setting cement for highway roadbeds

A high-speed, slow-setting technology, applied in the cement field, can solve the problems that the product is difficult to meet the technical requirements, and achieve the effects of broad market prospects, social benefits, good uniformity, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific examples are given to illustrate the present invention. It should be pointed out that the examples are only used to further illustrate the present invention, and do not represent the protection scope of the present invention. Non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

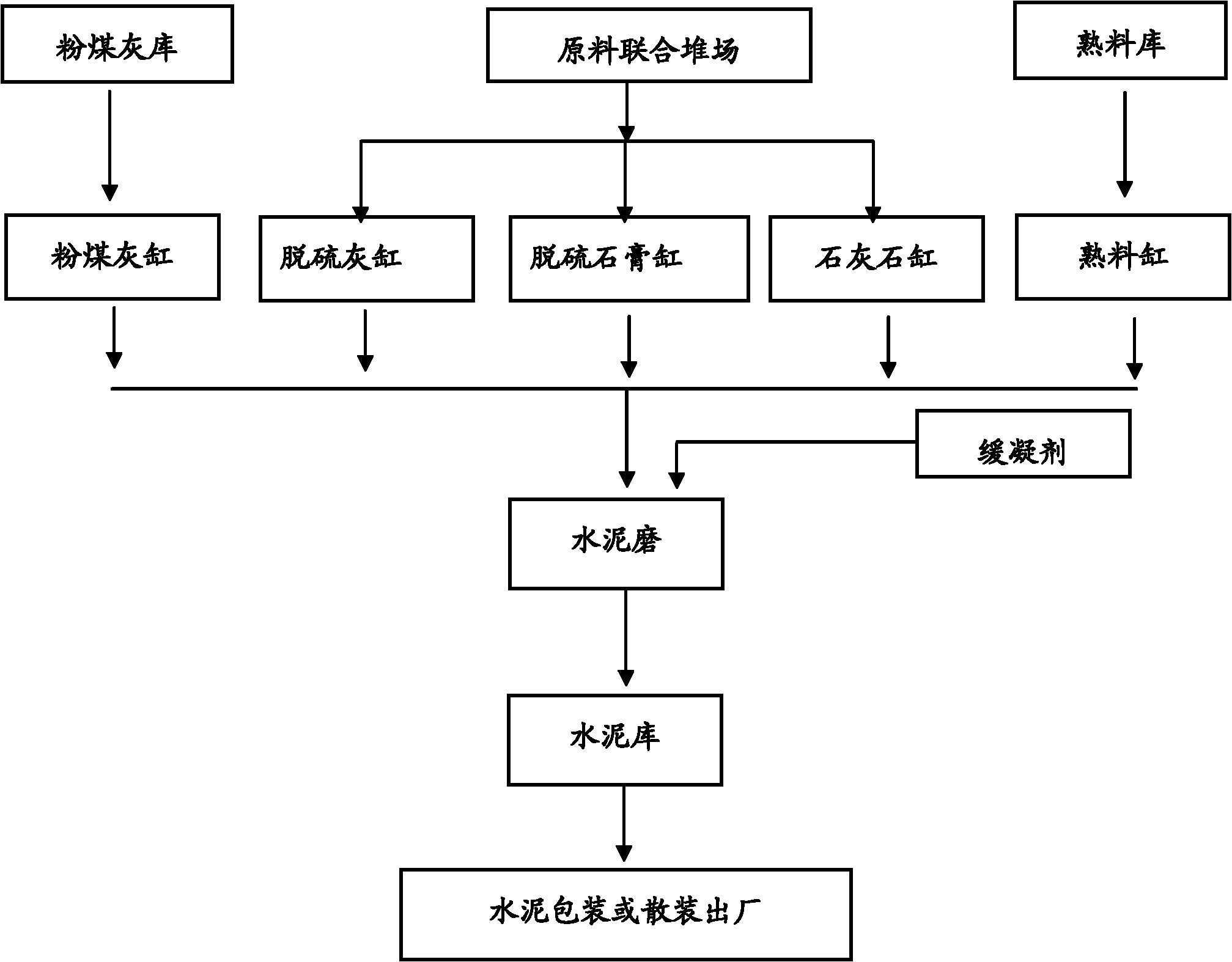

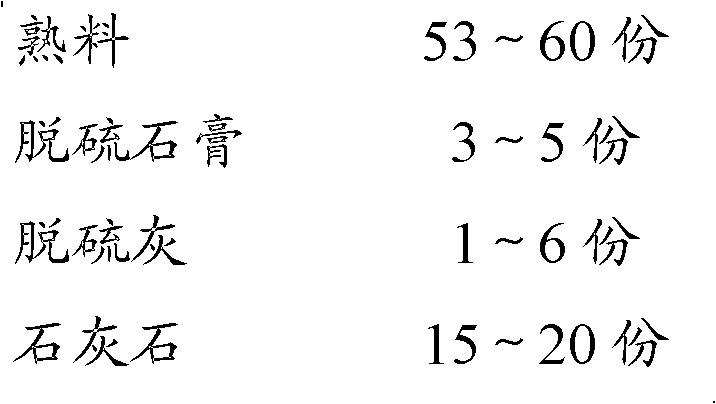

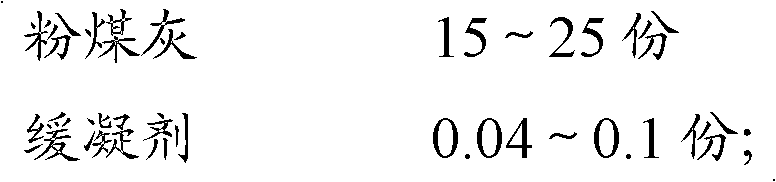

[0036] According to each raw material scope that the present invention sets, the retarded cement of embodiment 1-6 of the present invention all passes through figure 1 Prepared by the same process as shown. Table 1 is the raw material composition of each retarded cement in Examples 1-6, and Table 2 is the main minerals and chemical composition of the clinker in Examples 1-6. In an embodiment, the free calcium oxide in the desulfurization ash used is 5-10%, SO 3 10-25% and 15-25% moisture. The retarder used is Grace RDA series retarder (produced by Grace China Co., Lt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com