Beta-Ca2P2O7/CaSO4 multiphase biological ceramic and preparation method thereof

A -ca2p2o7, bioceramic technology, applied in medical science, prosthesis, etc., can solve problems such as fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

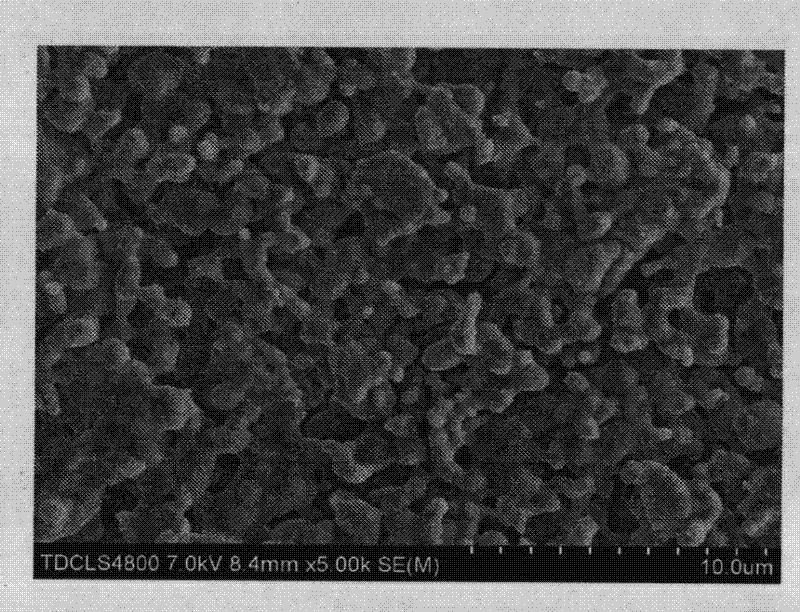

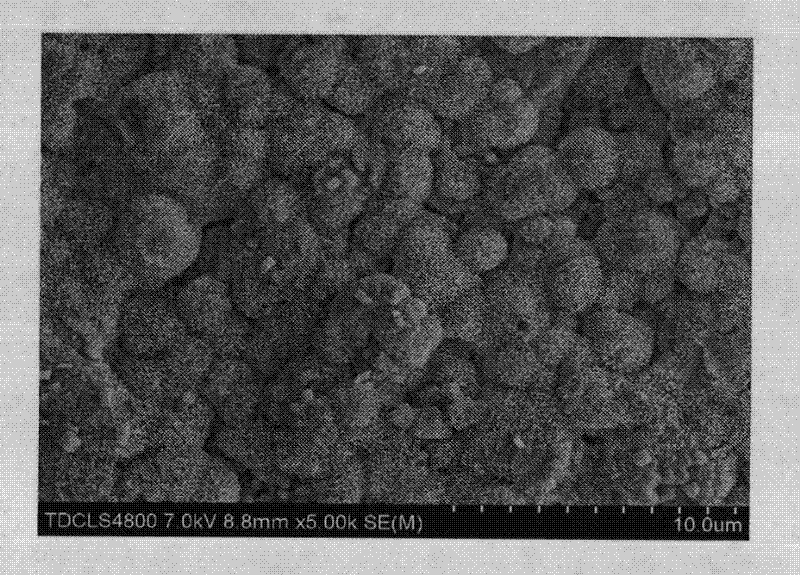

[0024] Example 1: The β-Ca 2 P 2 O 7 Powder and CaSO 4 The molar ratio of the powder is 1:0.2, the Ca / P molar ratio in the mixture is 1.1, and ethanol is used as the medium, and the ball mill is used for mixing for 1 hour. Dry in an oven at 80°C. Then use 5% polyvinyl alcohol solution as a binder to granulate the mixed powder, pass through a 30-mesh sieve, and press 50 MPa to form a Φ10x2mm disc. The dried sample was sintered at 920°C. The composite material obtained by sintering is made of β-Ca 2 P 2 O 7 And orthogonal CaSO 4 Crystal phase composition. The porosity of the sintered sample was 33%. After 14 days of degradation, the degradation weight loss was 0.72%. On the 9th day of degradation, dense bone-like hydroxyapatite formed on the surface of the sample. see figure 1 with figure 2 .

Embodiment 2

[0025] Example 2: The β-Ca 2 P 2 O 7 Powder and CaSO 4 If the molar ratio of the powder is 1:0.4, the Ca / P molar ratio in the mixture is 1.2 respectively. Ethanol is used as the medium and ball milled for 0.5h. Dry in an oven at 70°C. Then, using 5% ethyl cellulose solution as a binder, the mixed powder is granulated, passed through a 40-mesh sieve, and compressed with 80 MPa to form a Φ15x3mm disc. The dried sample was sintered at 950°C. The composite material obtained by sintering is made of β-Ca 2 P 2 O 7 And orthogonal CaSO 4 Crystal phase composition. The porosity of the sintered sample is 34%. After 14 days of degradation, the degradation weight loss was 0.82%. On the 9th day of degradation, dense bone-like hydroxyapatite formed on the surface of the sample.

Embodiment 3

[0026] Example 3: The β-Ca 2 P 2 O 7 Powder and CaSO 4 If the molar ratio of the powder is 1:0.8, the Ca / P molar ratio in the mixture is 1.4 respectively. Ethanol is used as the medium and the ball mill is used for mixing for 1.5 hours. Dry in an oven at 60°C. Then, using 7% polyvinyl alcohol solution as a binder, the mixed powder was granulated, passed through a 60-mesh sieve, and pressed with 50 MPa to form a test piece of 10×10×2 mm. The dried sample was sintered at 980°C. The composite material obtained by sintering is made of β-Ca 2 P 2 O 7 And orthogonal CaSO 4 Crystal phase composition. The porosity of the sintered sample is 38%. After 14 days of degradation, the degradation loss was 0.9%. On the 7th day of degradation, dense bone-like hydroxyapatite formed on the surface of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com