Light substrate for seedling in wood non-woven fabric container

A non-woven container, light-weight substrate technology, applied in soilless cultivation, application, organic fertilizer and other directions, can solve the problem that the substrate for seedlings is not suitable for the use of non-woven container substrate, the restrictions on promotion and application, the intensification of factory-based breeding of tree and flower varieties, The problems of scale, automation and standardization are difficult to achieve, so as to achieve the effect of improving nutrient utilization rate, low transportation cost and excellent seedling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

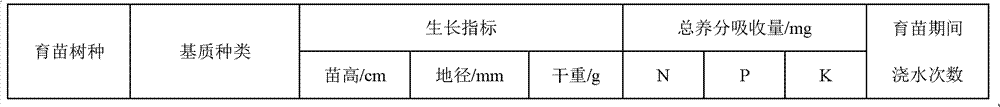

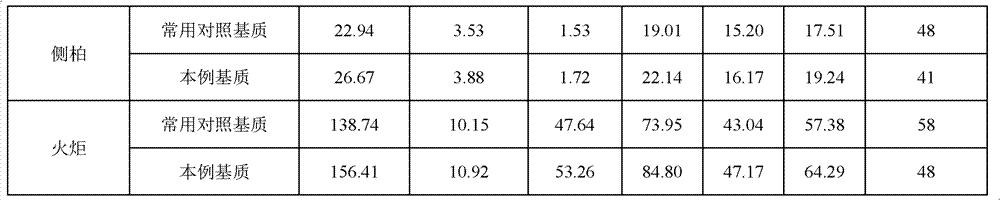

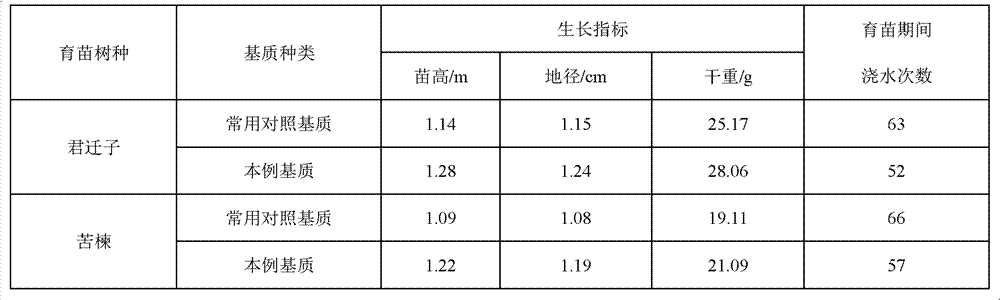

Examples

Embodiment 1

[0024] Embodiment 1 prepares forest tree non-woven fabric container seedling raising light matrix

[0025] The formula of the main matrix material is: 20 kg of peat, 35 kg of straw pulp and papermaking waste fermentation material, 15 kg of wood pulp and papermaking waste fermentation material, 20 kg of perlite, and 10 kg of vermiculite;

[0026] The formula of the fertilizer is: based on the weight of the matrix main material as S, the dosage is as follows: 0.05% S urea, 0.3% S superphosphate, 0.03% S potassium chloride, 0.5% S controlled release fertilizer, controlled The controlled release time of fertilizer release is 6 months, and the nutrient content is 15-10-10;

[0027] The disinfection material is carbendazim, and the amount of carbendazim added is 0.12% of S;

[0028] The pH adjustment material is ferrous sulfate, and the addition of ferrous sulfate is 0.3% of S;

[0029] The water retaining agent is cross-linked polyacrylamide, and the addition amount of cross-link...

Embodiment 2

[0036] Embodiment 2 prepares forest tree non-woven fabric container seedling-raising light matrix

[0037] The formula of the matrix main material is: 25 kg of peat, 30 kg of straw pulp and papermaking waste fermentation material, 15 kg of wood pulp and papermaking waste fermentation material, 20 kg of perlite, and 10 kg of vermiculite;

[0038]The formula of the fertilizer is: based on the weight of the matrix main material as S, the dosage is as follows: 0.1% S urea, 0.5% S superphosphate, 0.05% S weight potassium chloride, 0.2% S weight controlled release fertilizer , the controlled release time of the controlled release fertilizer is 4 months, and the nutrient content is 12-10-12;

[0039] The disinfection material is carbendazim, and the addition amount of carbendazim is 0.10% of S;

[0040] The pH adjustment material is ferrous sulfate, and the amount of ferrous sulfate added is 0.4% of S

[0041] The water retaining agent is cross-linked polyacrylamide, and the additi...

Embodiment 3

[0048] Embodiment 3 prepares forest tree non-woven fabric container seedling raising lightweight matrix

[0049] The formula of the main matrix material is: 30 kg of peat, 40 kg of straw pulp and papermaking waste fermentation material, 10 kg of wood pulp and papermaking waste fermentation material, 15 kg of perlite, and 5 kg of vermiculite;

[0050] The formula of the fertilizer is: based on the weight of the matrix main material as S, the dosage is as follows: 0.08% S urea, 0.4% S superphosphate, 0.04% S potassium chloride, 0.4% S controlled release fertilizer, controlled The controlled release time of fertilizer release is 4 months, and the nutrient content is 15-8-15;

[0051] The disinfection material is carbendazim, and the amount of carbendazim added is 0.08% of S;

[0052] The pH adjustment material is ferrous sulfate, and the addition of ferrous sulfate is 0.5% of S

[0053] The water retaining agent is cross-linked polyacrylamide, and the addition amount of cross-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com