Manufacturing method of micro lead delay detonating detonator

A production method and detonating tube technology, applied in the direction of detonating cord, etc., can solve the problems of increased safety risk, reduced delay accuracy, and poor detonation reliability, so as to save metal materials, prolong the delay time, and improve the delay accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

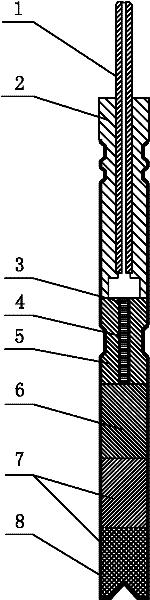

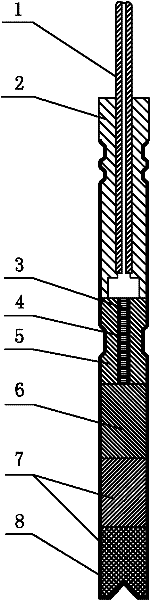

[0028] Such as figure 1 shown, including the following steps:

[0029] 1) Put delay medicine 3 in the aluminum metal tube 4;

[0030] 2) drawing the metal tube 4 loaded with the delay drug 3 into a thin metal tube with a diameter of 1.4mm-2.6mm;

[0031] 3) Carry out plastic coating to fine metal pipe, the plastic layer 5 of plastic coating thickness 1.5mm-2.5mm, forms extension body;

[0032] 4) Cut the extension body into extension elements with a length of 8mm-200mm;

[0033] 5) assemble and make detonator.

[0034] The aluminum metal tube 4 is an aluminum tube or an aluminum alloy tube.

[0035] The delay medicine is uniformly prepared by mixing the following raw materials in parts by weight: 30 parts of red lead, 5 parts of silicon and 0-6 parts of antimony trisulfide. Tungsten-based delay drugs or boron-based delay drugs can also be used.

[0036] The method of assembling the detonator is as follows: press the delay element into the tube shell 8, carry out card-in-...

Embodiment 2

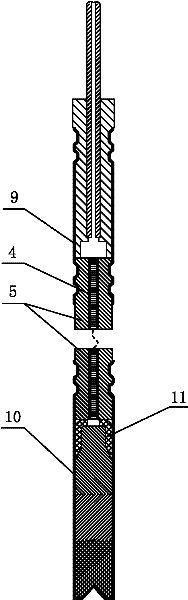

[0038] Such as figure 2 As shown, the detonator assembly method is as follows: the delay element is pressed into the split shell, and the two ends of the delay element are respectively fixed to the upper shell 9 and the lower shell 10 (that is, the shell of the fire detonator), and the upper end of the delay element is used The sealing plug connects and fixes the detonator and the upper shell 9, and the lower end of the extension element is sealed with the fire detonator to make a finished product.

[0039] When fixing, adopt card printing to fix, and a reinforcing cap 11 is set between the primer 6 of the fire detonator and the delay element.

[0040] In the present invention, the original detonator 1, the sealing plug 2, the fire detonator composed of the priming charge 6 and the high explosive 7, as well as the operation of card printing and card printing are common prior art, and its setting and use are required by those skilled in the art master.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com