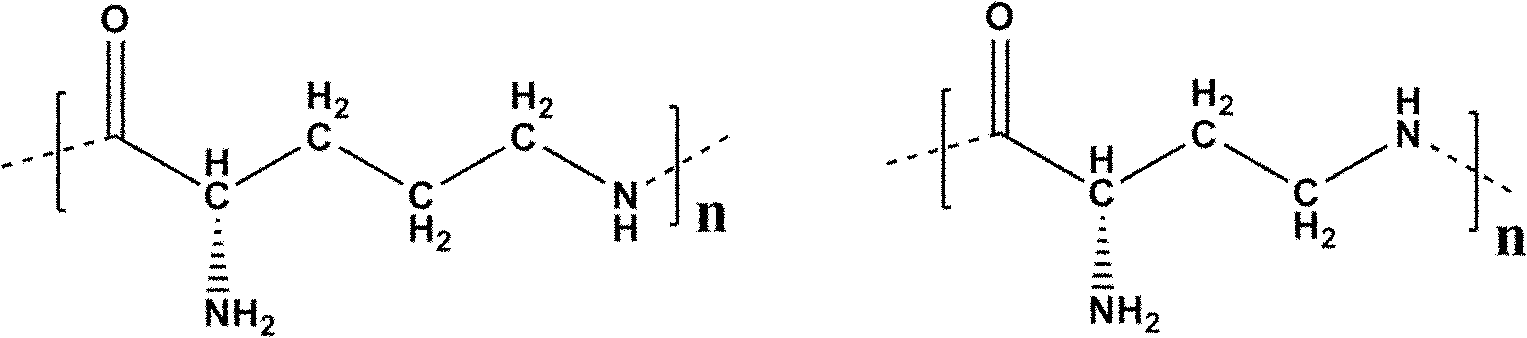

Streptomyces albulus and application thereof in preparing polylysine and poly-diamino-butyric acid

A technology of polydiaminobutyric acid and Streptomyces parvus, which is applied in the field of fermentation engineering, can solve the problems of no diaminobutyric acid, etc., and achieve the effects of extensive cultivation conditions, improved product production rate, and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Free fermentation of S.albulus PD-1 in a 5L tank to produce polylysine and polydiaminobutyric acid

[0039] Incline medium: glucose 10g / L, beef extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, agar 20g / L, pH 7.0.

[0040] Seed medium: glucose 10g / L, beef extract 5g / L, yeast extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, use 6mol / L NaOH solution to adjust pH 7.0

[0041] Fermentation medium: glucose 50g / L, yeast extract 5g / L, (NH 4 ) 2 SO 45g / L, Na 2 HPO 4 12H 2 O 1.58g / L, K 2 HPO 4 ·7H 2 O 0.82g / L, MgSO 4 ·7H 2 O 0.1g / L, use 6mol / L NaOH solution to adjust the pH to 7.0.

[0042] Cultivate Streptomyces albus S. albulus PD-1 (CCTCC NO: M2011043) in the seed medium, 28°C, 200r / min shaker conditions for 24h, and 300mL of seed liquid was mixed with 10% (v / v) seed The amount of inoculation was carried out in a fermenter pre-installed with 2.7L sterilized fermentation medium for free culture. The culture conditions were: 28°C, 400r / mi...

Embodiment 2

[0043] Example 2: Production of polylysine and polydiaminobutyric acid by immobilized fermentation of S.albulus PD-1

[0044] Incline medium: glucose 10g / L, beef extract 2g / L, peptone 2g / L, agar 20g / L, pH 7.0.

[0045] Seed medium: glucose 10g / L, beef extract 5g / L, yeast extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, use 6mol / L solution to adjust the pH to 7.0.

[0046] Fermentation medium: glucose 50g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, Na 2 HPO 4 12H 2 O 1.58g / L, K 2 HPO 4 ·7H 2 O 0.82g / L, MgSO 4 ·7H 2 O 0.1g / L, use 6mol / L NaOH solution to adjust the pH to 7.0.

[0047] Cultivate Streptomyces albus S.albulus PD-1 at 28°C and 200r / min on a shaker for 24 hours, inoculate 300mL of seed solution at 10% (v / v) in a pre-packed 2.7L sterilized In the final immobilization reactor, the immobilization reactor is constructed with reference to patent 200910030330.4. Culture conditions: 28°C, 400r / min, ventilation rate 3L / min, the pH value of the fermentat...

Embodiment 3

[0048] Embodiment 3: repeated batches of fermentation polylysine and polydiaminobutyric acid

[0049] Incline medium: Glucose 1g / L, beef extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L agar 20g / L, pH 7.0.

[0050] Seed medium: glucose 10g / L, beef extract 5g / L, yeast extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, use 6mol / L NaOH solution to adjust pH 7.0

[0051] Fermentation medium: glucose 50g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, Na 2 HPO 4 12H 2 O 1.58g / L, K 2 HPO 4 ·7H 2 O 0.82g / L, MgSO 4 ·7H 2 O 0.1g / L, use 6mol / L NaOH solution to adjust the pH to 7.0.

[0052] The fermentation process proceeds as follows:

[0053] Step 1. Cultivate Streptomyces parvus S.albulus PD-1 (CCTCC NO: M2011043) in the seed medium, 28°C, 200r / min shaker conditions for 24h, and 300mL seed solution was mixed with 10% (v / v ) seeds were inoculated in a fermenter pre-installed with 2.7L sterilized fermentation medium for free culture, culture conditions: 28°C, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com