Retort furnace for heat treating metal workpieces

A metal workpiece and retort furnace technology, which is applied in the field of electric heating retort furnaces, can solve the problems of lack of convection part, which is decisive for gas heating and heating uniformity, and achieves the improvement of heat treatment efficiency, uniform heating and reduction of thermal induction load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0159] The variants of the invention are explained in detail on the basis of the following examples.

[0160] Variant I:

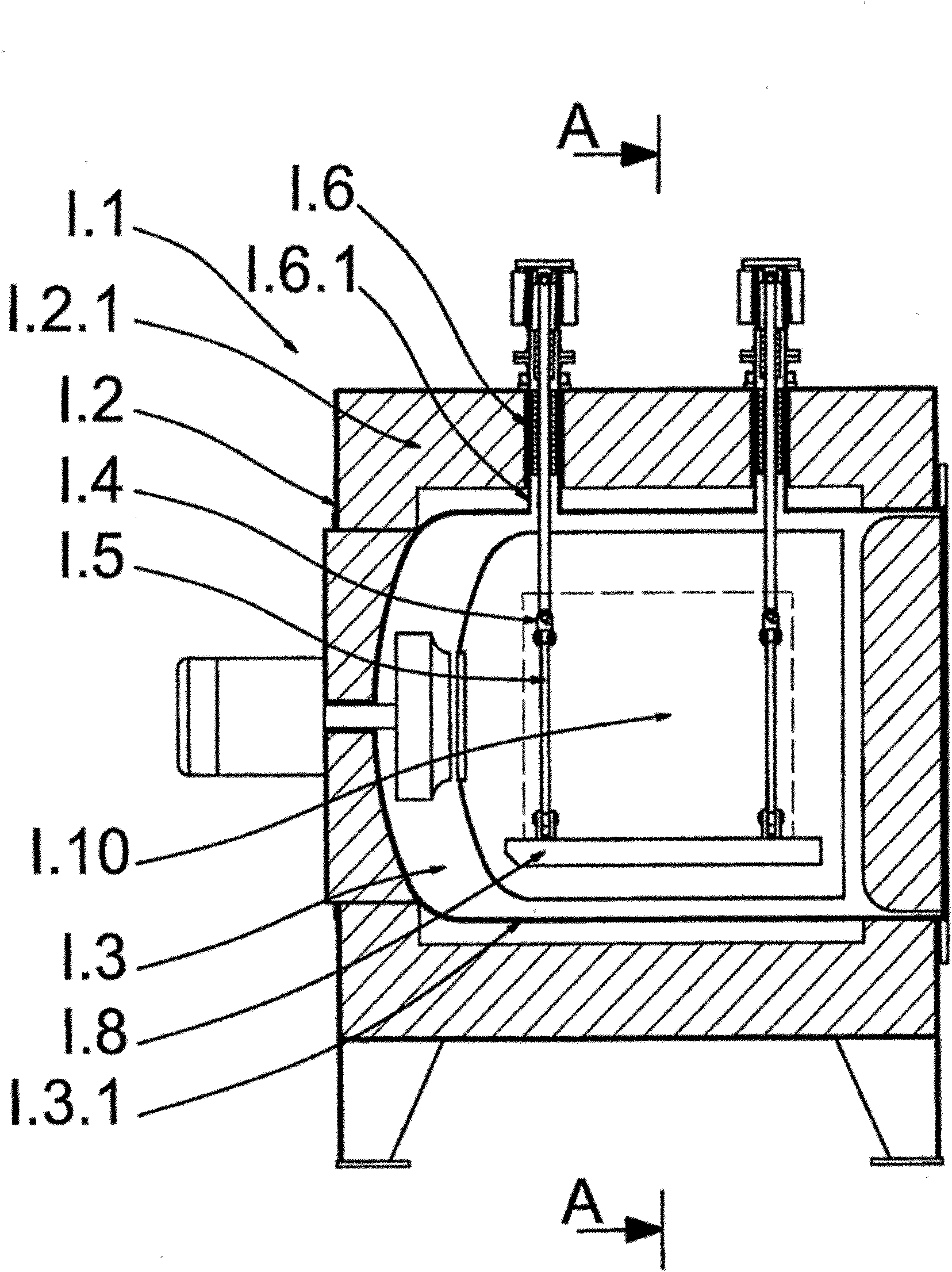

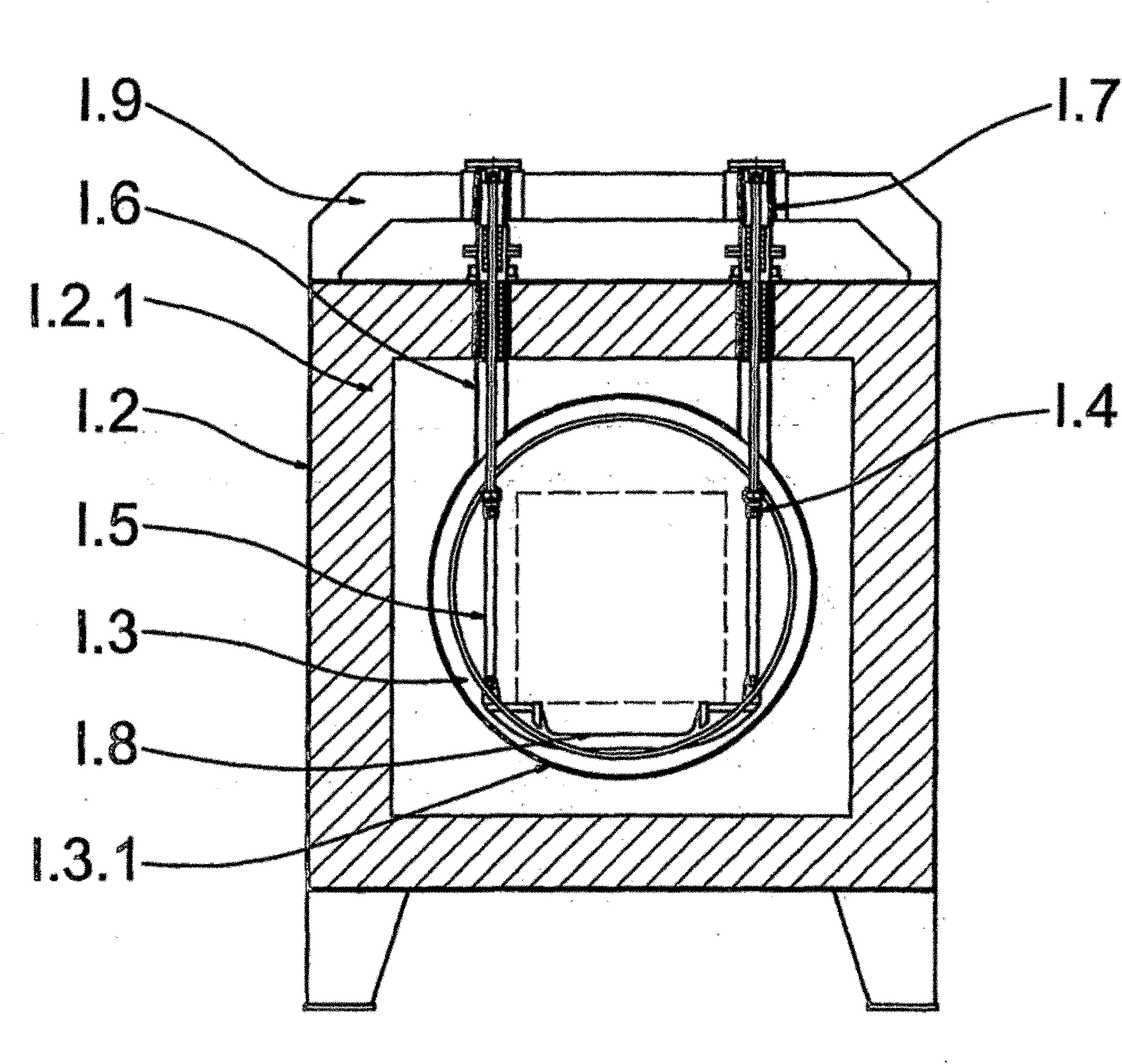

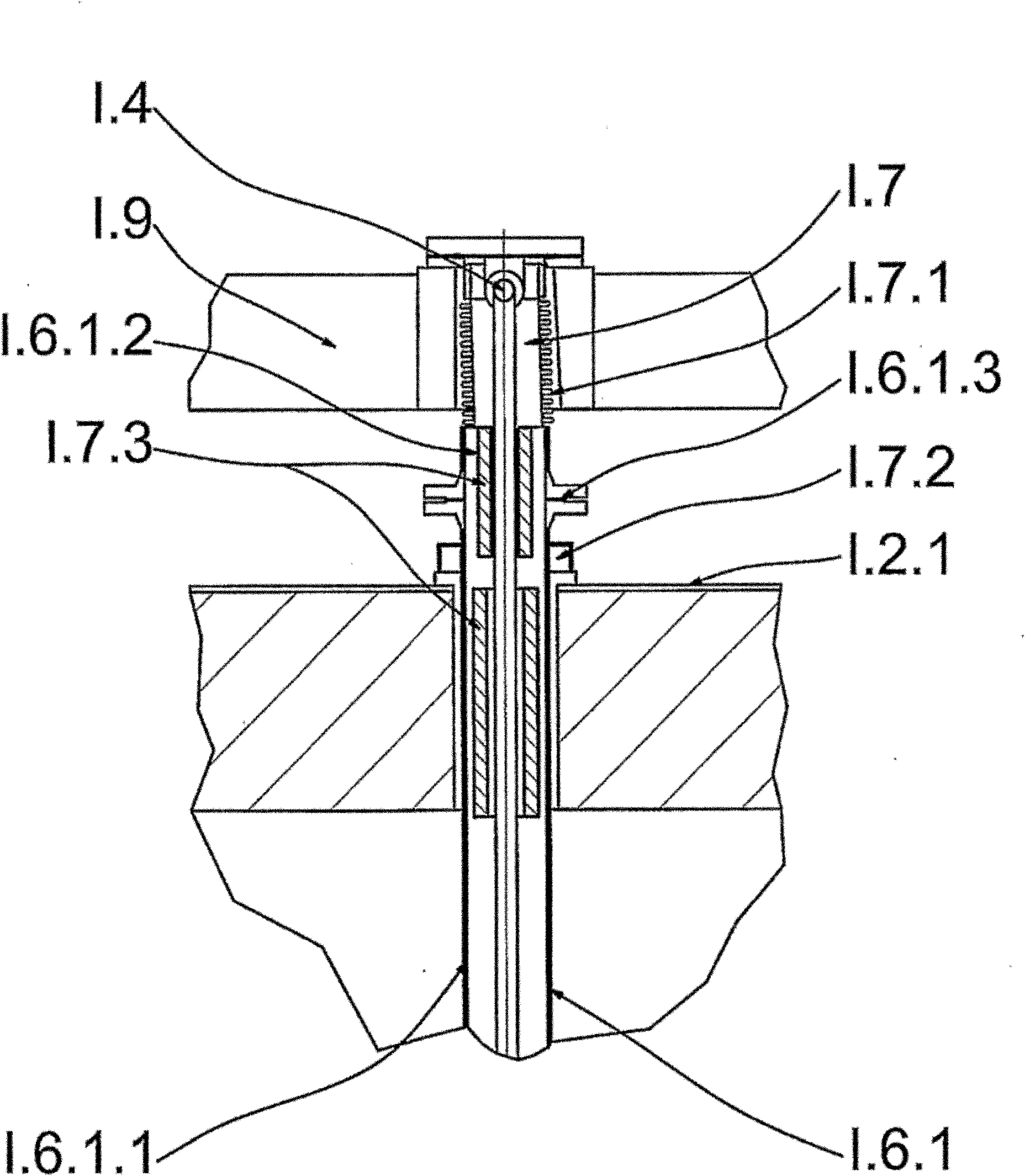

[0161] according to figure 1 with 2 , the retort furnace I.1 for the heat treatment of metal workpieces not described here comprises a metal horizontal tubular retort I.3 and a furnace hood I.2 surrounding the retort I.3. The retort I.3 has a gas-tight process chamber and material chamber I.10 for accommodating protective and reactive gases and a holding frame I.8 for positioning the material container, the process chamber or the material chamber for the workpiece (for example: materials) for heat treatment.

[0162] The furnace hood I.2 contains heating elements, not described here, which heat the retort I.3 and the treatment chamber or material chamber I.10 for the heat treatment of workpieces in protective gas. Furthermore, a fan unit not described here and a protective gas guide not described here in the retort furnace I.3 are contained in the reto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com