Mutual inductance type real-time on-line diagnosis and repair system for reliability of long-distance multi-node train line and use method thereof

A repair system and multi-node technology, which is applied in the field of real-time online diagnosis and repair system for train line reliability and mutual induction real-time online diagnosis and repair system for long-distance multi-node train line reliability. Completely sealed switchgear is scrapped and replaced, and technical requirements are high, so as to improve repair efficiency and reliability, facilitate operation, and reduce wear rate and cost expenditure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

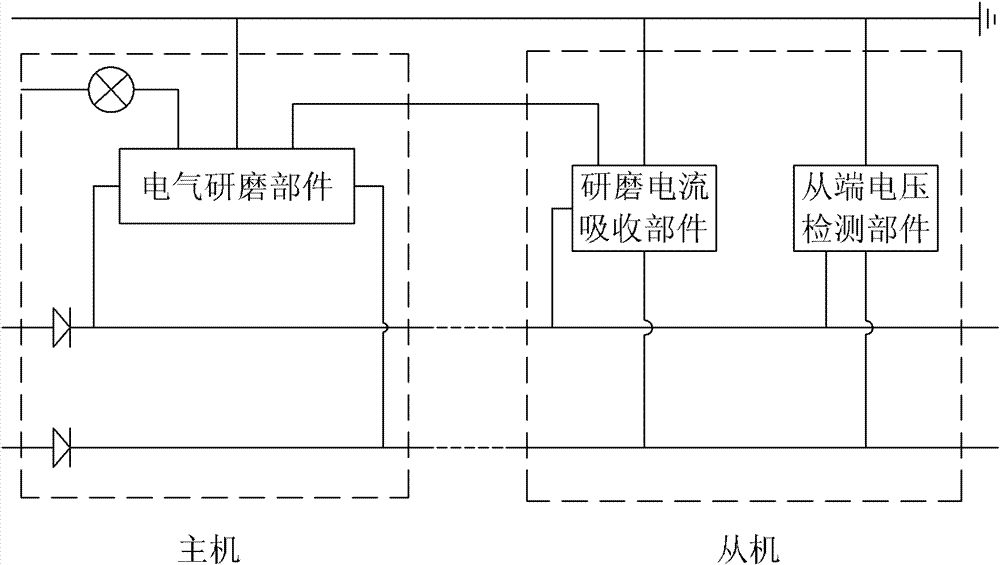

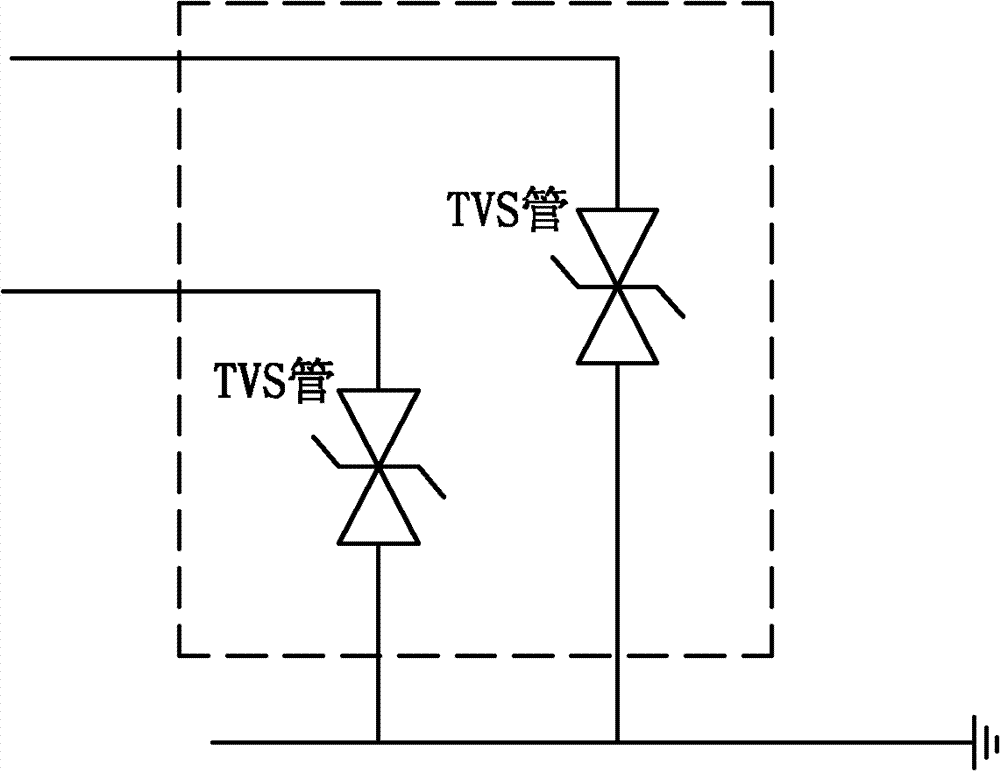

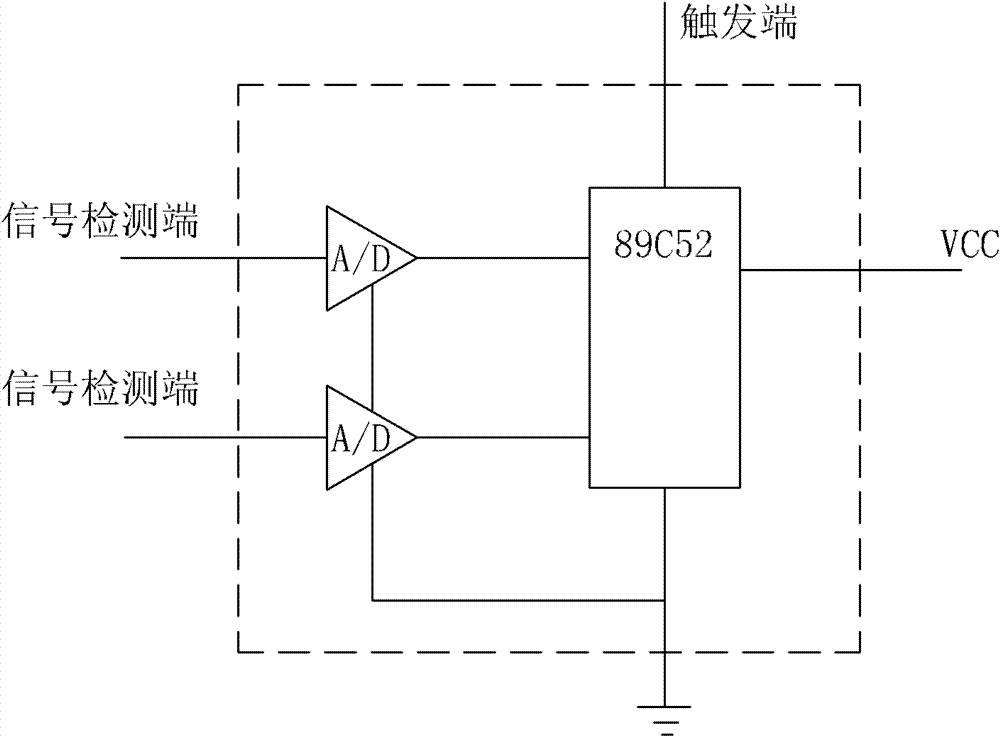

[0025] Such as Figures 1 to 3 As shown, the long-distance multi-node train line reliability mutual inductance real-time online diagnosis and repair system of the present invention adopts the transmission line pressure difference mutual inductance detection technology, which includes a master and a slave, the master is provided with electrical grinding parts, electrical grinding parts And connected to the tested line pair, the slave machine is provided with a grinding current absorbing part and a slave terminal voltage detecting part, the grinding current absorbing part and the slave terminal voltage detecting part are respectively parallel connected to the tested line pair and the grinding current absorbing part It is connected with the electric grinding part through a trigger control line. Further, one port of the electric grinding component, the grinding current absorbing component and the slave terminal voltage detecting component is respectively connected to the ground wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com