Centrifugal-type tree protectant spray brushing machine

A protective agent and centrifugal technology, which is applied in the field of centrifugal tree protective agent spraying machine, can solve the problems of health hazards for garden nurses, large differences in painting quality and environment, waste of protective agents such as limestone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

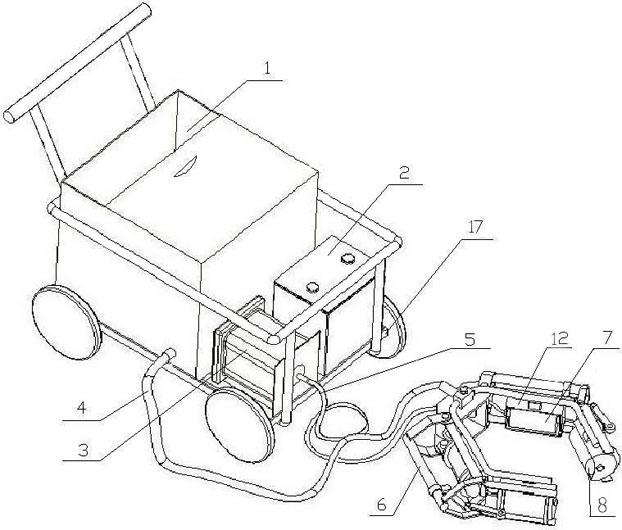

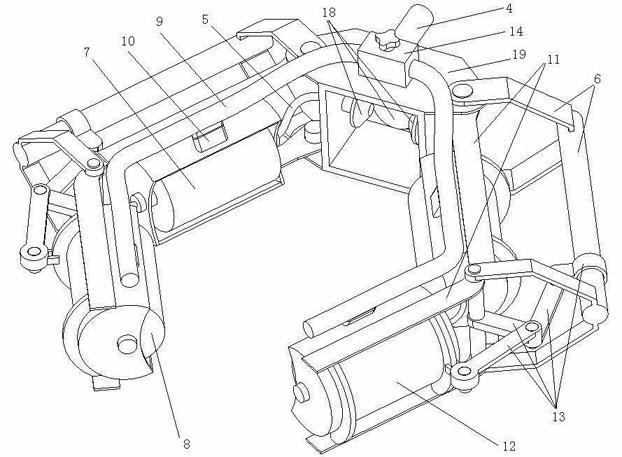

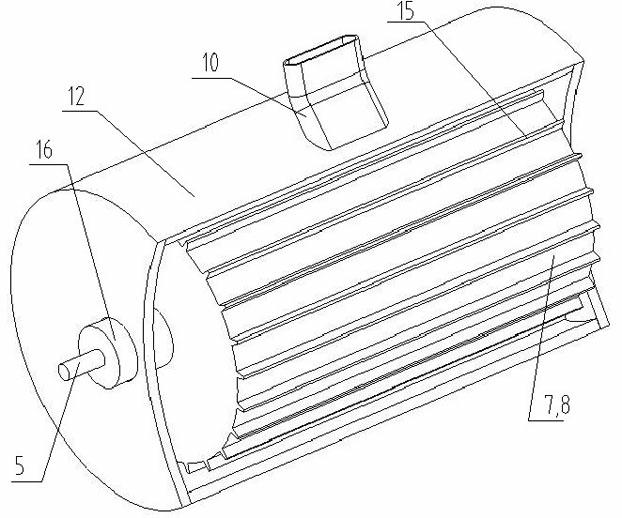

[0016] refer to figure 1 figure 2 image 3 , Centrifugal tree protective agent spraying machine, consists of three systems: centrifugal spraying, driving, and protective agent supply. Wherein four bracing frames 11, two joysticks 6, two joysticks 13, two rear end centrifugal rollers 7, two front end centrifugal rollers 8, four roller guide guards 12, four sub-transmission soft Shaft 5, two sub-transport hoses 9, and transmission shunt chamber 19 form a tree protection agent spraying system; wherein motor 3, battery 2, main drive flexible shaft 5, and bevel gear 18 constitute a drive system; wherein protection agent storage box 1 , Feed pump, trolley 17, stirring system, filter system, delivery hose 4, flow control valve 14, sub-delivery hose 9 to form a protective agent supply system.

[0017] This first embodiment is applied to smaller tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com