Diaphragm resin coating device and processing method

A processing method and diaphragm technology, applied in coatings, polycarbonate coatings, and devices for coating liquid on the surface, can solve problems such as capacity improvement, product quality control, and internal resistance reduction, so as to reduce energy consumption and Cost, product quality stability, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

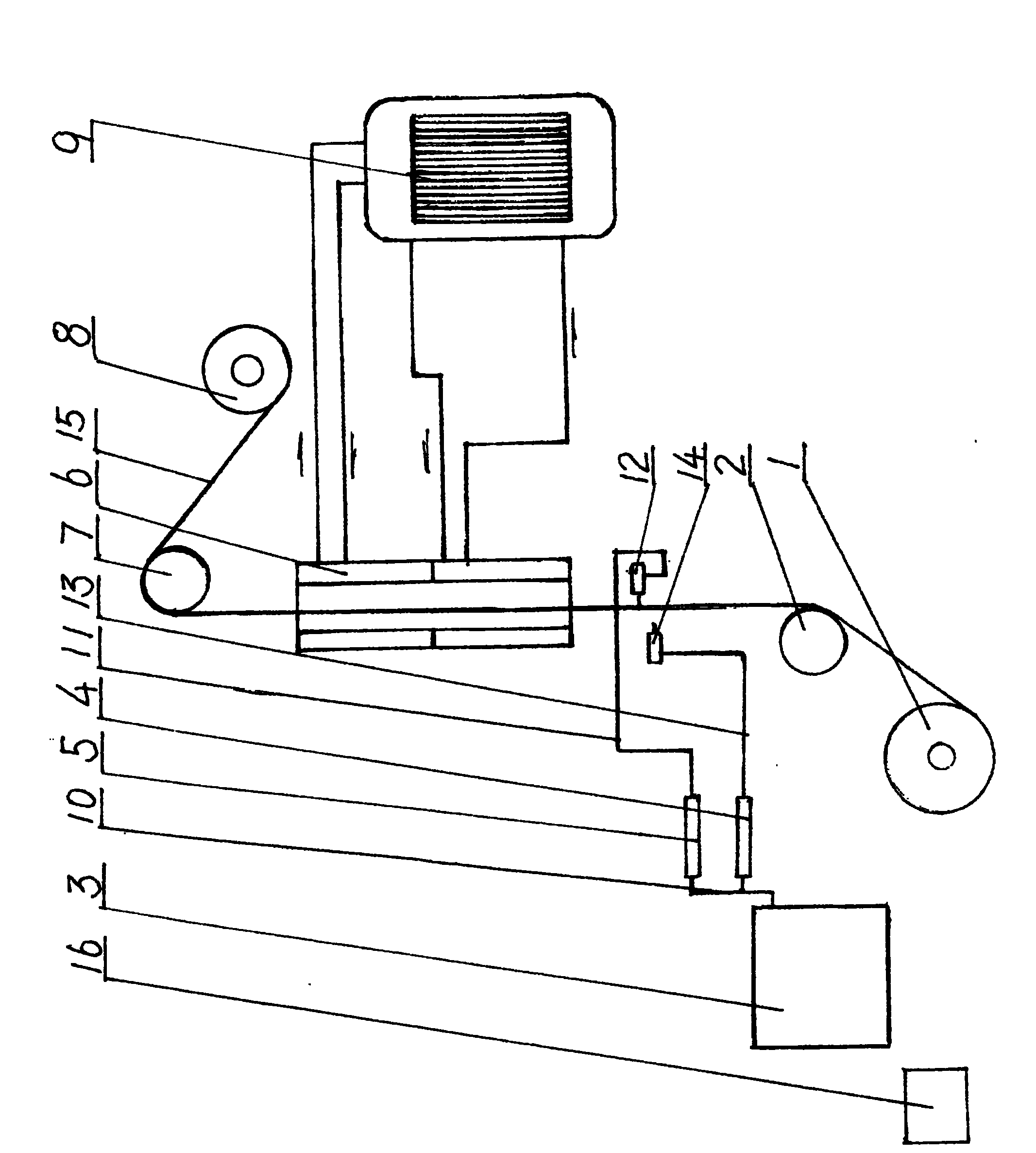

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

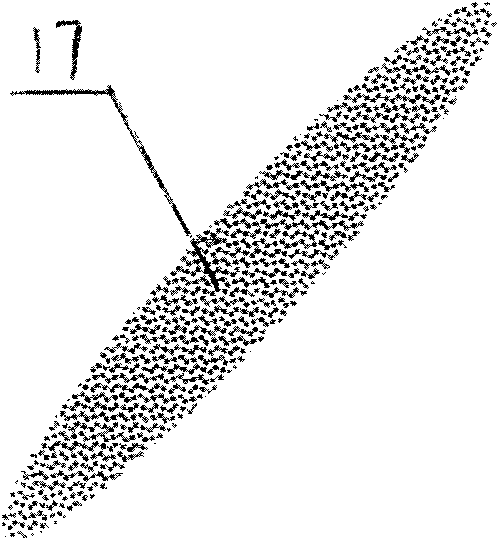

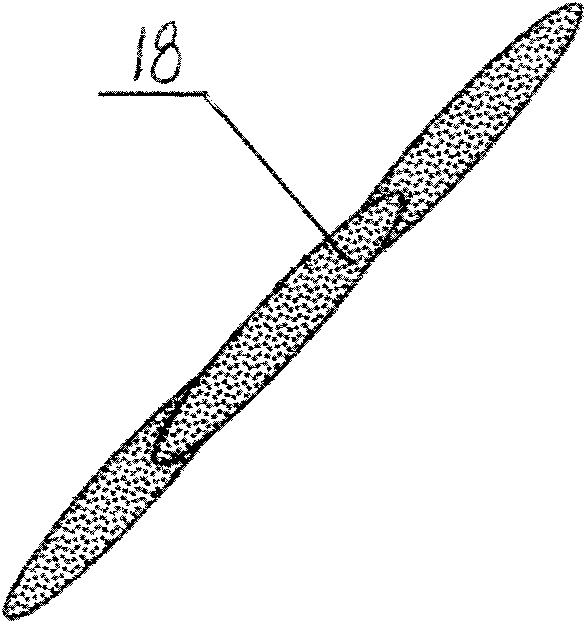

[0034] Such as figure 1 — image 3 Shown: a diaphragm resin coating equipment, characterized in that it includes an unwinder 1, A flattening roller 2, spraying material tank 3, A feeder 4, B feeder 5, two-stage drying Case 6, B flattening roller 7, winder 8 and air, steam generator 9, one end of described A feeder 4 and B feeder 5 is connected with spray material tank 3 by A pipeline 10, B The other end of feeder 5 is connected with A micropore nozzle 12 by B pipeline 11, and quantitative feeding, and the other end of A feeder 4 is connected with B micropore nozzle 14 by C pipeline 13, and quantitative feeding; The above-mentioned A flattening roller 2 and B flattening roller 7 are rubber rollers (or linear rollers) with a diameter of 100mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com