Method for preparing high-strength polymer composite material

A composite material and polymer technology, which is used in the field of preparing high-strength polymer composite materials, can solve problems affecting the performance of composite materials, and achieve the effects of improving bearing capacity, reducing chain end defects, and promoting orderly dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

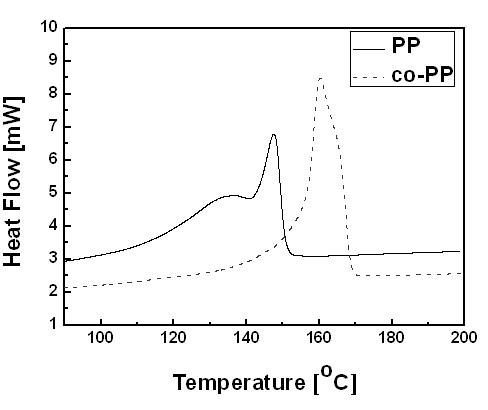

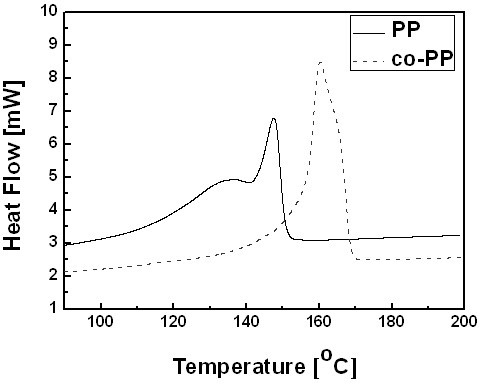

[0026] Table 1 shows the dosage ratio of each component of the reinforced phase embodiment of the present invention. The specific steps are as follows: the nano-inorganic particles are firstly modified by chemical grafting, and the graft monomer is butyl acrylate. The dosage ratio is shown in Table 1. The grafted modified nanoparticles and high melting point polypropylene were melt-blended in the mixer of Hakke torque rheometer to prepare masterbatch, and then the masterbatch and polypropylene were diluted in proportion. The oriented reinforcing phase (labeled A) was obtained by a solid-state drawing process. Table 2 is the formulation of comparative examples for injection molding.

[0027] A film with a thickness of 0.05mm~0.15mm is made into a film with a thickness of 0.05mm~0.15mm from the low melting point co-PP (marked as B) as the matrix phase.

[0028] Finally, we make composite material by reinforcing phase A and matrix phase B through thin layer laying-hot pressing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com