Energy-saving clean activated carbon production system

An activated carbon production and clean technology, applied in the direction of climate sustainability, inorganic chemistry, sustainable manufacturing/processing, etc., can solve the problems of air pollution, waste of active ingredients and heat, etc., to reduce pollution, reduce water consumption and Energy consumption and operation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

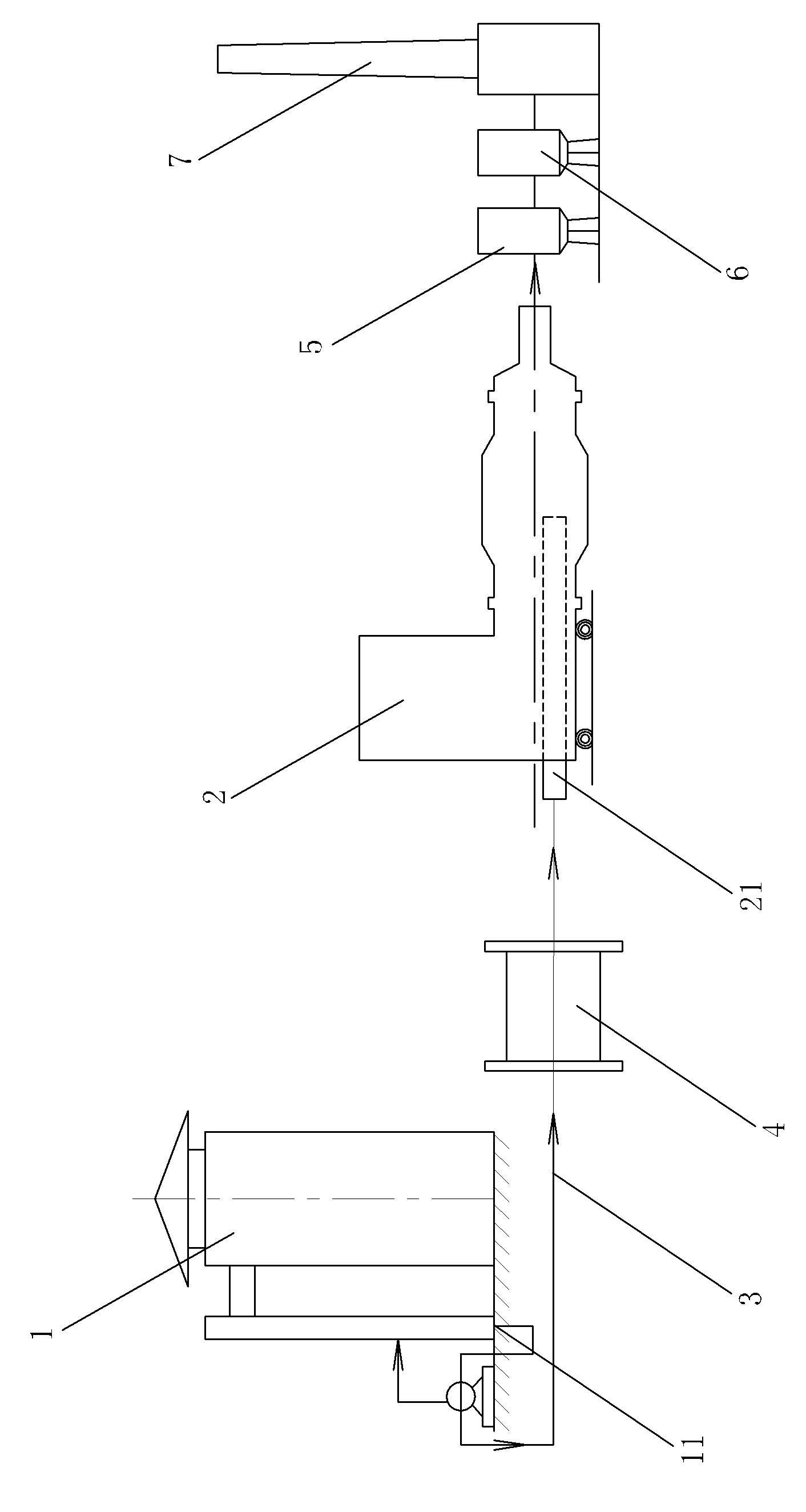

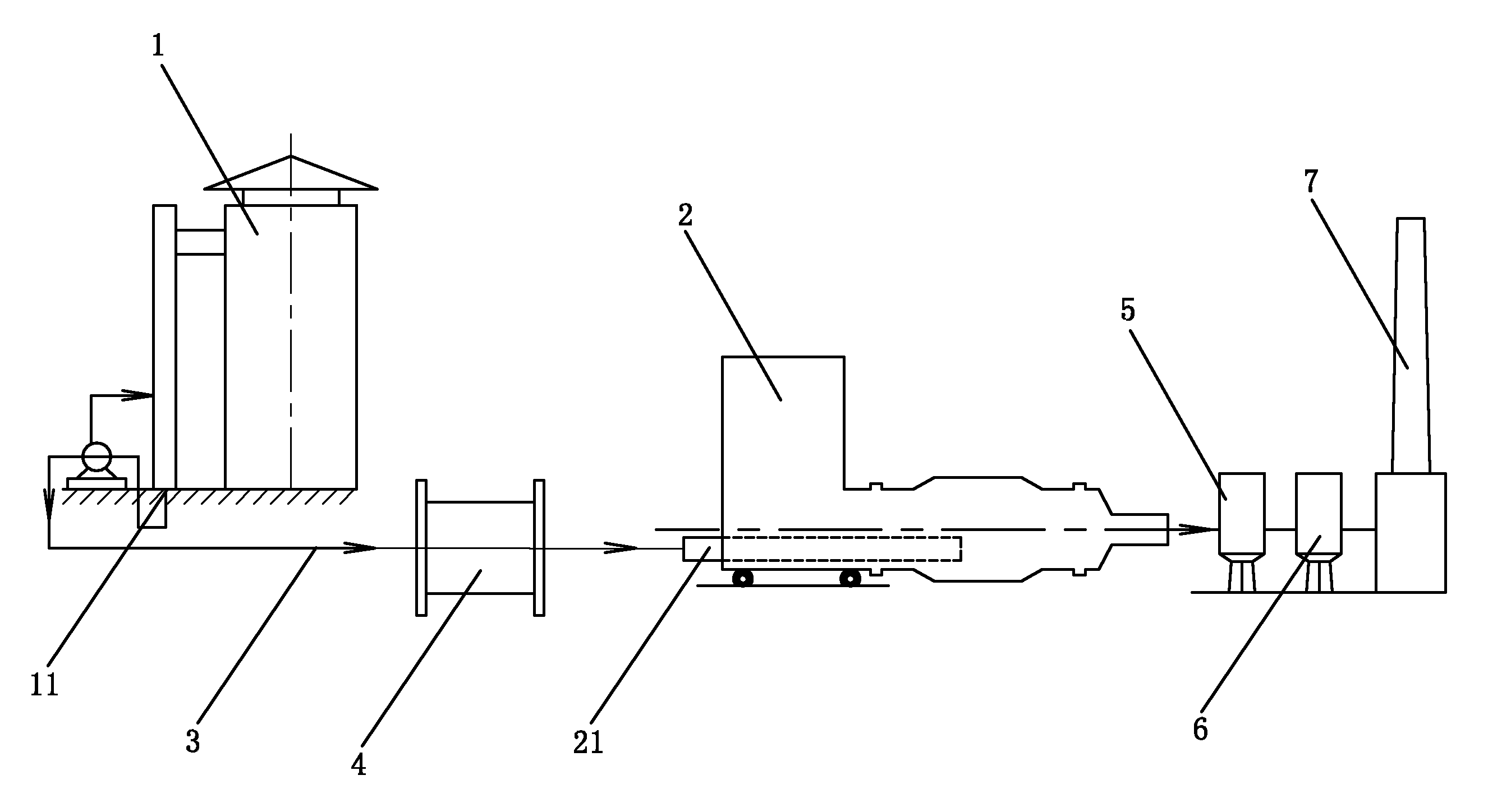

[0014] like figure 1 As shown, the energy-saving and clean activated carbon production system of the present invention comprises a Sleep furnace 1 and a rotary activation furnace 2, the bottom of the regenerator of the Sleep furnace 1 is provided with an activated tail gas discharge port 11, and the furnace head of the rotary activation furnace 2 is provided with a steam Pipe 21 , the activation exhaust outlet 11 of the Sleep furnace 1 communicates with the steam pipe 21 of the rotary activation furnace 2 through the flue gas pipe 3 . The flue gas pipe 3 is provided with an induced draft fan 4, and the tail gas outlet of the rotary activation furnace 2 is connected with the air inlet of the waste heat boiler 5 through the pipe. The exhaust port of the waste heat boiler 5 is connected to the air inlet of the desulfurization and dust removal device 6 through a pipeline. The desulfurization and dust removal device 6 adopts a gas integrated purification tower disclosed in Chinese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com