Method for recycling saltpeter-production dead steam

A technology of depleted steam and nitrate water, applied in chemical instruments and methods, alkali metal sulfites/sulfites, alkali metal compounds, etc., can solve the problems of heat energy loss, ecological environment pollution, waste, etc., and save energy costs , the effect of solving noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

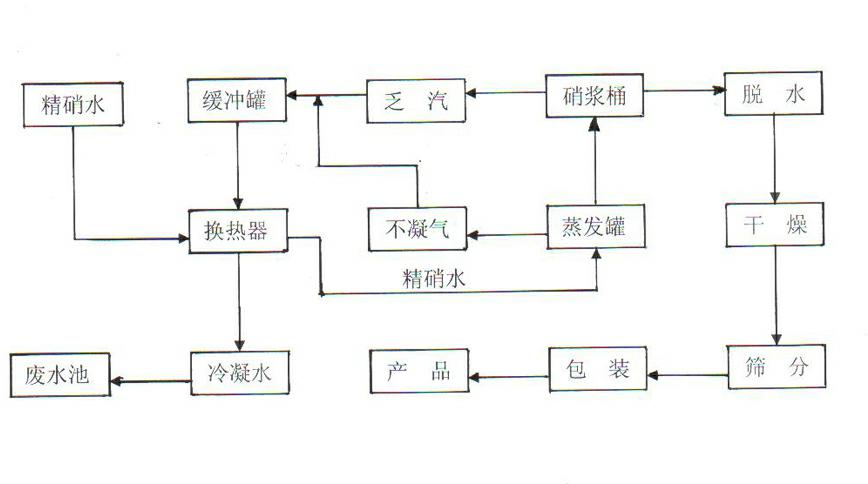

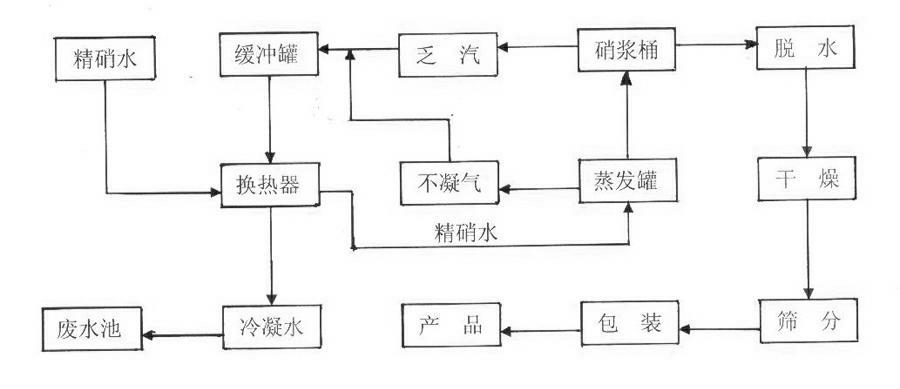

[0010] With reference to accompanying drawing: introduce the production method of a kind of exhaust gas recovery of the applicant to implement below, it comprises the steps: The condensed gas is collected in a closed buffer tank for temporary storage; 2. The refined nitric water with a temperature of 50°C is introduced into the heat exchanger, and the hot exhaust gas temporarily stored in the buffer tank is also introduced into the heat exchanger. Heat exchange in the heater to raise the temperature to 56°C; 3. Discharge the condensed water after the heat exchange of exhaust steam into the waste water pool; 4. Transport the preheated refined nitric acid water into the evaporation tank through the centrifugal pump It is heated and evaporated, concentrated and crystallized in the nitrous slurry tank, then dehydrated, dried, sieved and packaged, and finally becomes the finished product of industrial anhydrous sodium sulfate. Wherein, heating and evaporating in the evaporating tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com