Preparation method for 3-methyl-3-butene-1-alcohol

A technology of butene and methyl, which is applied in the field of preparation of 3-methyl-3-buten-1-ol, can solve the problems of high production cost and large investment, and achieve low production cost, low investment and reduced energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

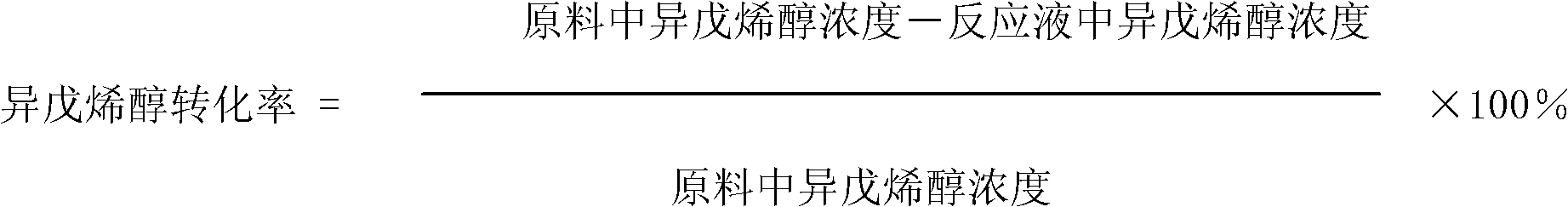

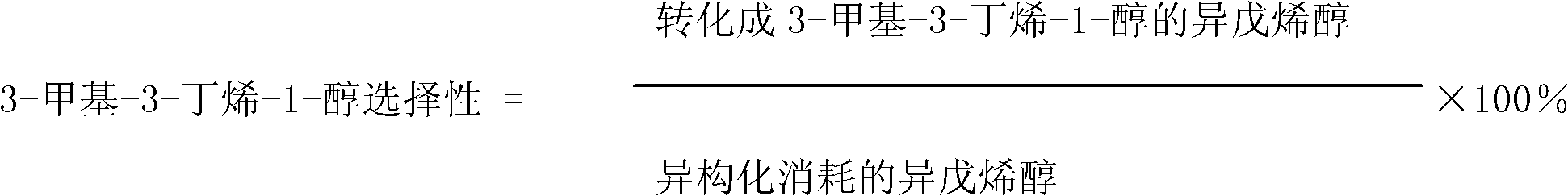

[0029] The isomerization reaction is carried out in a φ25mm×510mm glass ebullating bed reactor. A baffle full of small holes and a hydrogen gas distributor are placed at the bottom of the reactor. The aperture of the baffle and distributor is about 0.01mm. The raw material inlet and The gas distributor is located under the baffle. The reaction product and hydrogen outlets are located at the upper part of the reactor, and a condensing reflux device with a vent is placed on the top of the reactor.

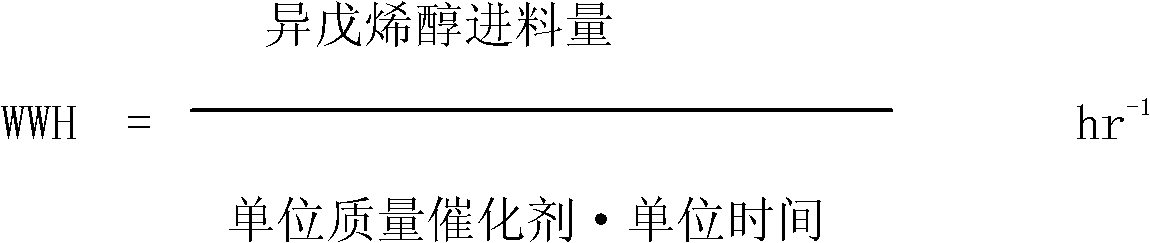

[0030] 20 grams of an amorphous modified Raney nickel catalyst with a particle size of 0.03-0.05 mm is added to the reactor, and the catalyst is placed on a baffle. Hydrogen enters the reactor from the gas distributor, and the hydrogen space velocity is 20-100hr -1 , the reactor is heated up to 50-120°C, and then the temperature is maintained to pump prenol into the reactor continuously for reaction, and the prenol load WWH of the catalyst is controlled to be 3.0-6.0hr -1 , the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com