Hot-melt pressure-sensitive adhesive for polyethylene materials and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and adhesives, applied in adhesives, mineral oil hydrocarbon copolymer adhesives, adhesive types, etc., can solve the problems of poor bonding effect of polyethylene materials and achieve the best results Good, good initial viscosity, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

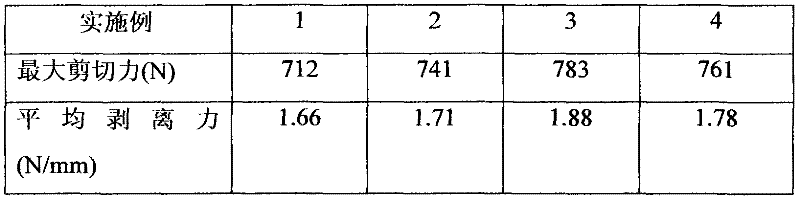

Embodiment 1

[0034] Add petroleum resin 30Kg, polyisobutylene 30Kg, antioxidant di-tert-butyl p-cresol 0.75Kg and [β-(3,5-di-tert-butyl 4-hydroxyl Phenyl) propionic acid] pentaerythritol ester 0.25Kg, light stabilizer TINVUN622 0.75Kg and CHIMASSORB944 0.25Kg. Heat up the oil bath to 180°C, keep warm for 30 minutes, and then add 15kg of amorphous polyolefin (APAO), 15kg of thermoplastic elastomer (SIS), and 15kg of ethylene-octene copolymer (POE), and wait until amorphous polyolefin (APAO), Turn on the kneader after the thermoplastic elastomer (SIS) and ethylene-octene copolymer (POE) are completely dissolved. The temperature is controlled at 180°C and stirred for 60 minutes, all the resins are melted and mixed into a uniform viscous liquid, and the stirring is stopped, and the hot-melt pressure-sensitive adhesive is prepared. Coated on a high-density polyethylene (HDPE) sheet, the thickness of the hot-melt pressure-sensitive adhesive is about 0.3mm. Determination of the adhesive propert...

Embodiment 2

[0036] Add petroleum resin 40Kg, polyisobutylene 30Kg, antioxidant di-tert-butyl p-cresol 0.25Kg and [β-(3,5-di-tert-butyl 4-hydroxyl Phenyl) propionic acid] pentaerythritol ester 0.75Kg, light stabilizer TINVUN622 0.25Kg and CHIMASSORB944 0.75Kg. Heat up the oil bath to 180°C, keep warm for 30 minutes, add 15kg of amorphous polyolefin (APAO), 15kg of thermoplastic elastomer (SIS), 15kg of ethylene-octene copolymer (POE), and wait until the amorphous polyolefin (APAO), thermoplastic The kneader was started after the elastomer (SIS) and ethylene-octene copolymer (POE) were completely dissolved. The temperature is controlled at 180° C. and stirred for 60 minutes, all the resins are melted and mixed well, and the stirring is stopped, and the preparation of the hot-melt pressure-sensitive adhesive is completed. Coated on a high-density polyethylene (HDPE) sheet, the thickness of the hot-melt pressure-sensitive adhesive is about 0.3mm. Determination of the adhesive properties of ...

Embodiment 3

[0038] Add petroleum resin 30Kg, polyisobutylene 40Kg, antioxidant di-tert-butyl p-cresol and [β-(3,5-di-tert-butyl 4-hydroxyphenyl ) propionic acid] pentaerythritol ester 0.5Kg each, light stabilizer TINVUN622 and CHIMASSORB944 each 0.5Kg. Heat up the oil bath to 180°C, keep warm for 30 minutes, add 10kg of amorphous polyolefin (APAO), 10kg of thermoplastic elastomer (SIS), 10kg of ethylene-octene copolymer (POE), and wait until amorphous polyolefin (APAO), thermoplastic The kneader was started after the elastomer (SIS) and ethylene-octene copolymer (POE) were completely dissolved. The temperature is controlled at 180° C. and stirred for 60 minutes, all the resins are melted and mixed well, and the stirring is stopped, and the preparation of the hot-melt pressure-sensitive adhesive is completed. Coated on a high-density polyethylene (HDPE) sheet, the thickness of the hot-melt pressure-sensitive adhesive is about 0.3mm. Determination of the adhesive properties of hot melt pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com