Treatment method of roasting arsenium-containing gold ore concentrate

A treatment method and technology of gold concentrate, which is applied in the field of roasting pre-oxidation treatment of arsenic-containing gold concentrate, can solve the problems of high gold grade in cyanide tailings, incomplete smoke and dust roasting, high smoke and dust rate, etc., and achieve improved leaching recovery The effect of improving the efficiency, ensuring the roasting quality and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

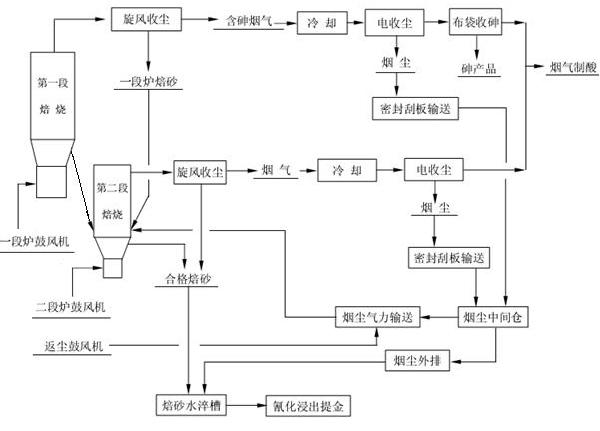

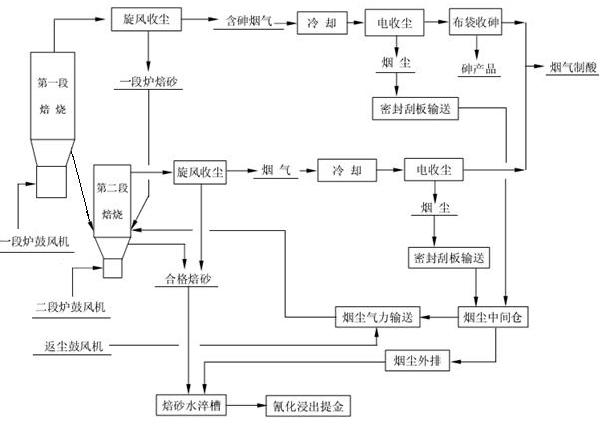

Image

Examples

Embodiment 1

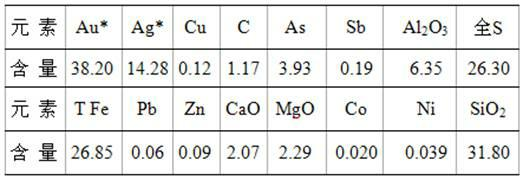

[0016] The main chemical components of the arsenic-containing gold concentrate are listed in Table 1.

[0017] Table 1 Embodiment 1—Chemical element composition (%) of arsenic-containing gold concentrate

[0018]

[0019] *Note: The units of Au and Ag are g / t.

[0020] Spray arsenic-containing gold concentrate with a slurry concentration of 68% into the first-stage roaster, blow 85% of theoretical air into the first-stage roaster, and control the roasting temperature to 550°C. The dust-collected calcined sand and the calcined sand from the overflow port of the first-stage furnace are discharged into the second-stage furnace. The flue gas after dust collection in the first stage furnace cyclone is cooled to 380°C and then enters the electric precipitator for dust collection. After dust collection, the flue gas is collected for arsenic collection, and the flue gas is sent to the acid purification system after collection.

[0021] The first-stage furnace cyclone dust-collect...

Embodiment 2

[0027] The main chemical components of the arsenic-containing gold concentrate are listed in Table 2.

[0028] Table 2 Embodiment 2—Chemical element composition (%) of arsenic-containing gold concentrate

[0029]

[0030] *Note: The units of Au and Ag are g / t.

[0031] Spray the arsenic-containing gold concentrate with 70% slurry concentration into the first-stage roaster, blow 90% of the theoretical amount of air into the first-stage roaster, control the roasting temperature at 580°C, and collect the generated flue gas through the cyclone. The dust-collected calcined sand and the calcined sand from the overflow port of the first-stage furnace are discharged into the second-stage furnace. The flue gas after dust collection by the cyclone of the first stage furnace is cooled to 345°C and then enters the electric dust collector for dust collection. After dust collection, the flue gas is collected for arsenic, and the flue gas is sent to the acid purification system after col...

Embodiment 3

[0038] The main chemical components of the arsenic-containing gold concentrate are listed in Table 3.

[0039] Table 3 Embodiment 3—chemical element composition (%) of arsenic-containing gold concentrate

[0040]

[0041] *Note: The units of Au and Ag are g / t.

[0042] Spray arsenic-containing gold concentrate with a slurry concentration of 69% into the first-stage roasting furnace, blow 88% of theoretical air into the first-stage roaster, control the roasting temperature at 550°C, and collect the generated flue gas by cyclone. The dust-collected calcined sand and the calcined sand from the overflow port of the first-stage furnace are discharged into the second-stage furnace. The flue gas after dust collection by the cyclone of the first stage furnace is cooled to 320°C and then enters the electric dust collector for dust collection. After dust collection, the flue gas is collected for arsenic collection, and the flue gas is sent to the acid purification system after colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com