A kind of extraction method of gold and silver in clay graphite crucible slag

A technology of graphite crucible and extraction method, which is applied in the field of silver extraction and gold in clay graphite crucible slag, which can solve technical difficulties, inability to effectively extract gold and silver from clay graphite crucible slag, zero recovery rate, etc., and achieve high The effect of recycling efficiency, sufficient source of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]1) Stir and react the clay graphite crucible slag powder with a particle size of 150 mesh and sulfuric acid / fluorosilicic acid mixture at 50°C for 12 hours. After the reaction is completed, the mixed solution is cooled to room temperature, washed with water until neutral, and filtered to obtain filter residue and filtrate ; wherein the concentration of sulfuric acid in the sulfuric acid / fluorosilicic acid mixed solution is 80g / L, and the concentration of fluorosilicic acid is 100g / L; the mass volume ratio of clay graphite crucible slag powder and sulfuric acid / fluorosilicic acid mixed solution is 1:3g / ml ;

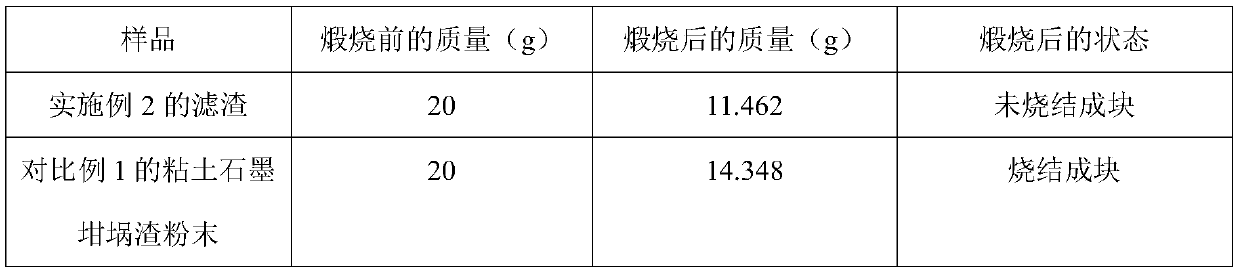

[0045] 2) After the filter residue was dried at 105°C for 12 hours, it was calcined at 950°C for 3 hours, and the calcined filter residue was cooled and ground to obtain powdery enrichment residue;

[0046] 3) Put the enriched slag in a nitric acid solution with a concentration of 100g / L, stir at room temperature for leaching reaction for 5 hours, dilute the mixed so...

Embodiment 2

[0049] 1) Stir and react the clay graphite crucible slag powder with a particle size of 200 mesh and sulfuric acid / fluorosilicic acid mixture at 60°C for 8 hours. After the reaction is completed, the mixed solution is cooled to room temperature, washed with water until neutral, and filtered to obtain the filter residue and filtrate ; wherein the concentration of sulfuric acid in the sulfuric acid / fluorosilicic acid mixed solution is 100g / L, and the concentration of fluorosilicic acid is 220g / L; the mass volume ratio of clay graphite crucible slag powder and sulfuric acid / fluorosilicic acid mixed solution is 1:2g / ml ;

[0050] 2) After the filter residue was dried at 105°C for 12 hours, it was calcined at 900°C for 2 hours, and the calcined filter residue was cooled and ground to obtain powdery enrichment residue;

[0051] 3) Put the enriched slag in a nitric acid solution with a concentration of 63g / L, stir at room temperature for leaching reaction for 4 hours, dilute the mixe...

Embodiment 3

[0054] 1) Stir and react the clay graphite crucible slag powder with a particle size of 325 mesh and sulfuric acid / fluorosilicic acid mixture at 70°C for 6 hours. After the reaction is completed, the mixed solution is cooled to room temperature, washed with water until neutral, and filtered to obtain the filter residue and filtrate Wherein the concentration of sulfuric acid in the sulfuric acid / fluorosilicic acid mixed solution is 150g / L, and the concentration of fluorosilicic acid is 340g / L; the mass volume ratio of clay graphite crucible slag powder and sulfuric acid / fluorosilicic acid mixed solution is 1:1g / ml ;

[0055] 2) After the filter residue was dried at 105°C for 12 hours, it was calcined at 1000°C for 1.5 hours, and the calcined filter residue was cooled and ground to obtain powdery enrichment residue;

[0056] 3) Put the enriched slag in a nitric acid solution with a concentration of 130g / L, stir at room temperature for leaching reaction for 6 hours, dilute the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com