Silver nanometer material and application thereof

A technology of silver nanometer and silver nanoparticle, applied in nanotechnology, nanotechnology, nano-optics and other directions, can solve problems such as increased insertion loss and high pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] 1. Preparation of silver nanomaterials

[0013] The preparation of the silver nano material of the present invention can adopt the nanosphere etching method, "natural etching technique", and nanosphere etching technology, and the nanosphere etching technique is recommended here. The following is a detailed description of the nanosphere etching technology:

[0014] (1) Preparation of nanosphere mask plate;

[0015] Required materials: polystyrene nanospheres (Duke Scientific Corp) with a diameter of 450±5nm, quartz substrate (10×10×0.2mm3), methanol, ethanol, sodium dodecylsulfate (dodecylsodiumsulfate, SDS), de ionized water. In addition, a vertical puller, a petri dish (7-9cm in diameter) and a micro-sampler (50uL) are required;

[0016] Substrate cleaning: soak the quartz substrate in piranha solution (3:1H2SO4:30%H2O2) at 80oC for 1.5 hours, wash it repeatedly with distilled water after cooling, and then ultrasonically clean it in 5:1:1H2O:NH4OH:30%H2O2 Bath for ...

example 1

[0024] Example 1 Double beam interference switch

[0025] Such as figure 2 As shown, the optical path is a typical two-beam interference structure, and the optical switching effect is realized through this simple structure. The two beams of light indicated in red are obtained by splitting the same laser beam, and the sample of the silver nanoparticle array described above is added to one of the beams. The adjustment makes the two paths of light have the same optical path, that is, they have the same phase, so that the effect of interference enhancement can be achieved. Since the power density of the signal light is weak, it is not enough to excite the nonlinear effect in the sample. At this time, a beam of laser light with a strong power density is incident on the sample (shown as the blue beam), and incident on the same area of the sample as the signal light. Due to the nonlinear effect of silver nanoparticles, the signal of this channel will Light produces a nonlinear ...

example 2

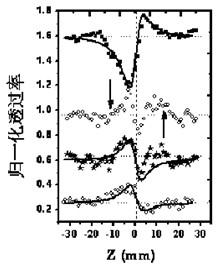

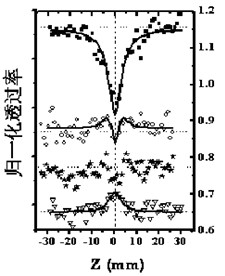

[0026] Example 2 Light-controlled ultrafast switch

[0027] if will figure 2 The excitation light and signal light in the system are also consistent in time, that is, the phase difference between the pump light and the signal light can be fine-tuned through the optical delay line, so that the pump light reaches the sample ahead of the signal light. Such as image 3 As shown, in a short time (~1 ps) after the excitation light is applied, the signal light transmittance changes suddenly, and then after about 40 ps, the signal light transmittance basically returns to the original state, indicating that the recovery time of the optical switch prepared by this sample is within On the order of picoseconds, it meets the needs of ultrafast optical switches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com