Nondestructive detection system and method for pulsed magnetic flux leakage defects and stresses

A non-destructive testing and defect technology, applied in pipeline systems, material magnetic variables, gas/liquid distribution and storage, etc., can solve problems such as failure to assess pipeline life and failure to detect pipeline stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

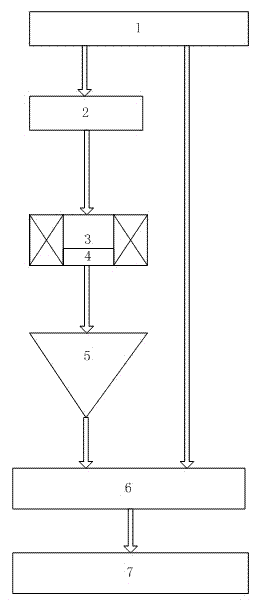

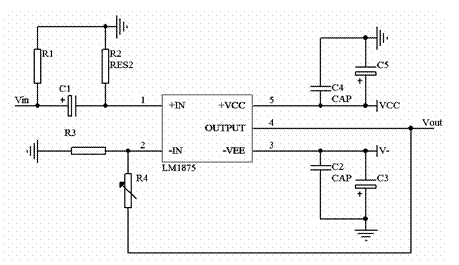

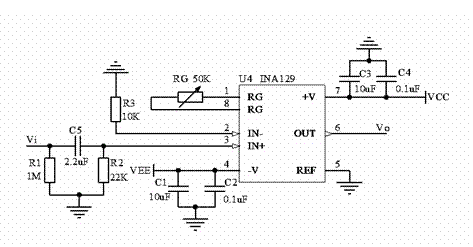

[0022] Such as figure 1 As shown, the nondestructive testing system of the present invention includes a signal generator 1, a power amplifier circuit 2, an excitation coil 3, a Hall sensor 4, a signal amplifier circuit 5, a data acquisition card 6 and a computer 7, wherein the output of the signal generator 1 is divided into Two paths are connected, one is connected to the input of the power amplifier circuit 2. The output of the power amplifier circuit 2 is connected to the excitation coil 3 wound on the iron core, and the output of the Hall sensor 4 is connected to the data acquisition card via the signal amplifier circuit 5. Input; the other is directly connected to the data acquisition card 6. The two signals enter the computer 7 through the data acquisition card 6, and use the powerful data processing capability of the computer 7 to realize the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com