Method and detection sensor for detecting optical fiber grating vibration of large-scale mechanized equipment

A fiber grating and large-scale machinery technology, applied in the field of sensors, can solve problems such as poor frequency dynamic response characteristics, obstacles to the application of rotating machinery, and inability to apply high-frequency measurement, etc., to achieve fast dynamic response, eliminate influence, and anti-electromagnetic interference. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

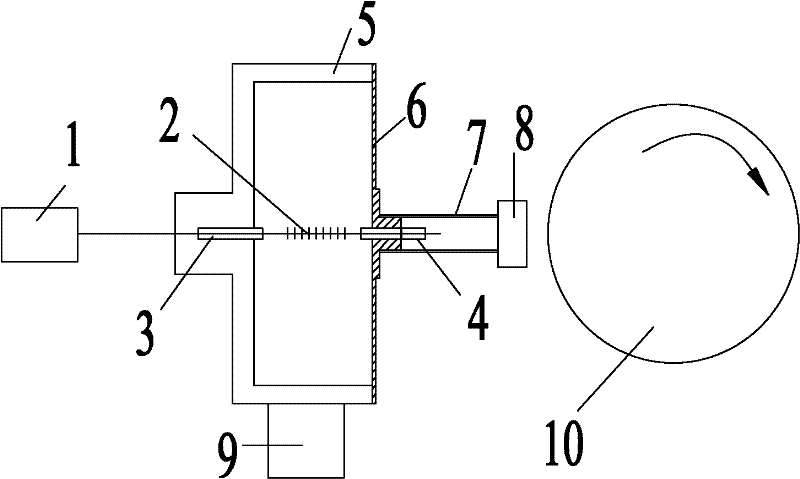

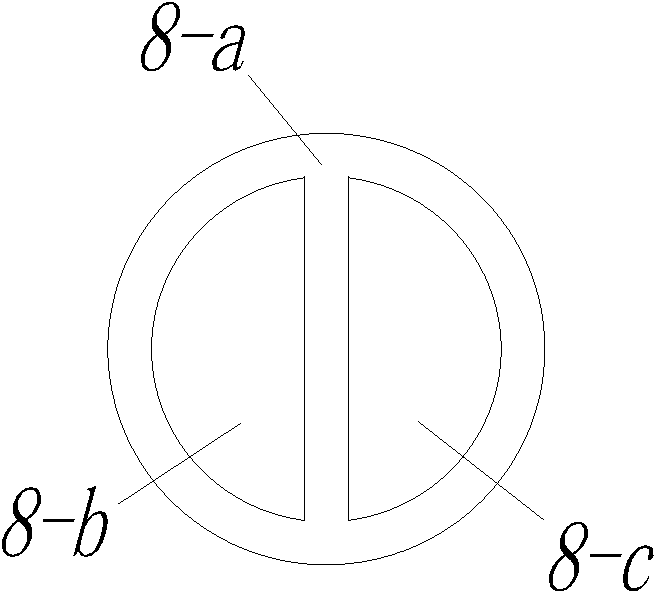

[0023] The overall installation structure of the non-contact fiber grating dynamic detection sensor: the two ends of the fiber grating 2 are respectively glued into the first capillary steel pipe 3 and the second capillary steel pipe 4, wherein the first capillary steel pipe 3 is connected to one end of the metal sleeve 5, The second capillary steel pipe 4 is connected to the central hard core of the metal diaphragm 6, and the metal diaphragm 6 is welded to the other end of the metal sleeve 5. During the installation process, the fiber grating 2 is pre-tightened, and the first magnet 8-b and The second magnet 8-c is a U-shaped sensing probe formed by connecting the soft iron 8-a—the magnetic coupling sensing probe 8, and the magnetic coupling sensing probe 8 is connected to the central hard core of the metal diaphragm 6 through the connecting rod 7 , which co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com