Unitized storage granary and storage method thereof

A granary and storage unit technology, which is applied to the unitized storage granary and its storage field, can solve the problems of unfavorable scientific management, high energy consumption, inconvenient monitoring measures, etc., to reduce environmental pollution, avoid mutual influence, and facilitate scientific management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

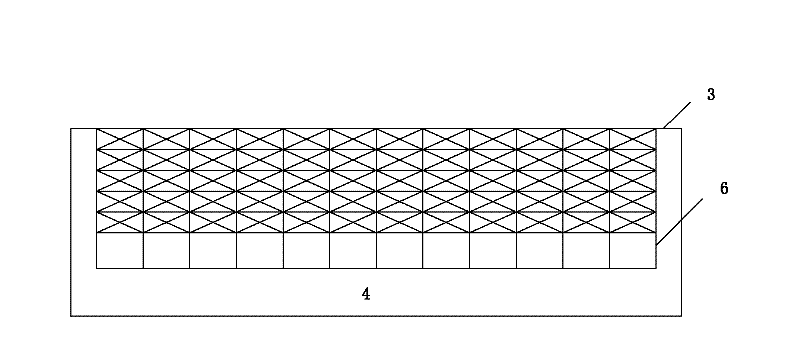

[0056] Such as figure 2 Shown is a schematic plan view of a warehouse in Embodiment 1 of the present invention. The storage unit 6 is located on one side of the warehouse 3, and the operation area 4 is located on the other side of the warehouse 3. The warehouse 3 is divided into 12 storage units 6, and the storage capacity of each storage unit 6 is equal. Each storage unit 6 connected settings are fixed storage units. The storage units 6 are arranged in a line along one side of the compartment 3 .

[0057] Each adjacent storage unit 6 uses one side of the compartment 3 as its own compartment wall, and there is a common compartment wall between each adjacent storage unit 6 . The operation area 4 runs through the entire warehouse 3, and the door of each storage unit 6 faces the operation area 4, so as to carry out the operation of grain entering and leaving the warehouse.

Embodiment 2

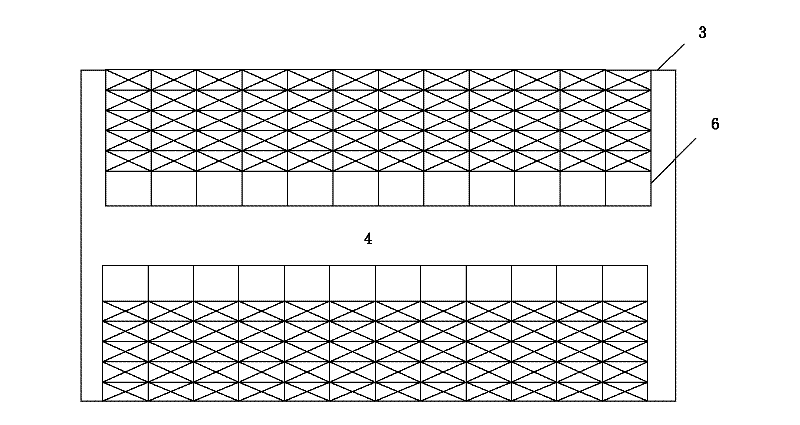

[0059] image 3 It is a schematic plan view of a warehouse in Embodiment 2 of the present invention. The working area 4 is located in the middle of the warehouse 3 and divides the warehouse 3 into two parts. The storage units 6 are respectively located on both sides of the warehouse 3 . In this embodiment, there are 24 storage units 6, and each storage unit 6 has the same capacity. The storage units 6 are arranged in a line along both sides of the warehouse 3, and there are 12 storage units 6 on each side of the warehouse. The warehouse walls are individual warehouse walls, and there is a common warehouse wall between each adjacent storage unit 6 . The working area 4 runs through the entire warehouse 3. Preferably, the working area 4 is also provided on both sides of the warehouse 3 without storage units 6, so as to facilitate logistics and storage operations. The doors of each storage unit 6 on both sides of the warehouse are all facing the operation area 4, and the doors ...

Embodiment 3

[0061] Figure 4 It is a schematic plan view of a warehouse in Embodiment 3 of the present invention. The storage unit 6 is located in the middle of the warehouse 3 , and the working areas 4 are respectively located on both sides of the warehouse 3 . In this embodiment, there are 24 storage units 6, and each storage unit 6 has the same capacity. The storage units 6 are arranged in two rows in the middle of the warehouse 3, each row has 12 storage units 6, and each adjacent storage unit 6 has a common warehouse wall. The operation area 4 is on both sides of the warehouse 3, running through the entire warehouse 3, and the doors of the two rows of storage units 6 are respectively facing the operation area 4, so as to facilitate the operation of grain entering and leaving the warehouse.

[0062] The invention also discloses a method for unitized grain low-temperature storage using the aforementioned unitized grain low-temperature storage storehouse. The method includes the steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com