High-temperature phase-transitional temperature-sensitive fire-extinguishing gel and preparation method thereof

A phase transition and gel technology, applied in fire protection equipment and other directions, can solve problems such as impact and environmental pollution, and achieve the effects of improving fire extinguishing performance, high phase transition temperature, and improving utilization efficiency and fire extinguishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

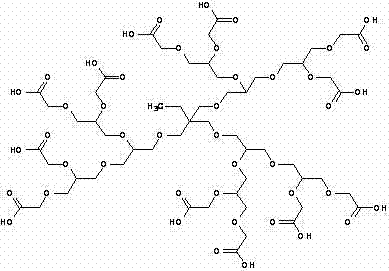

Image

Examples

Embodiment 1

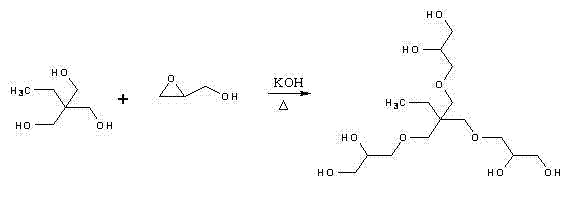

[0026] Example 1: Preparation of hydroxyl-terminated hyperbranched polyether G1, the chemical reaction formula is:

[0027]

[0028] Mix 1mol trimethylolpropane (134g) with 0.1mol KOH (5.6g), heat up to 100°C for dehydration and protonation, add dioxane and stir to dissolve, slowly add 3mol glycidol (222g) dropwise, and reflux for 10h. After cooling, it was neutralized with sulfuric acid, the white crystals were filtered off, and the solvent was distilled off under reduced pressure to obtain the product (356g).

Embodiment 2

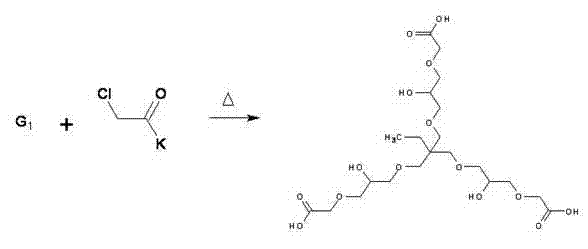

[0029] Embodiment two: the preparation of carboxyl-terminated hyperbranched polyether C11, chemical reaction formula is:

[0030]

[0031] Take 1mol of hydroxyl-terminated hyperbranched polyether G1 (356g), add appropriate amount of dioxane, stir and dissolve, mix with 3mol potassium monochloroacetate (397.5g) and heat up to reflux for 5 hours, filter out the crystals, and evaporate the solvent under reduced pressure to obtain the product (530g).

Embodiment 3

[0032] Embodiment three: the preparation of carboxyl-terminated hyperbranched polyether C12, chemical reaction formula is:

[0033]

[0034] Take 1 mol of hydroxyl-terminated hyperbranched polyether G1 (356g), add appropriate amount of dioxane and stir to dissolve, mix with 6 mol of potassium monochloroacetate (795g) and heat up to reflux for 5h, filter out the crystals, distill off the solvent under reduced pressure to obtain the product ( 704g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com