Powder sintering forming method for cutting tool and cutting body thereof

A cutting tool, sintering molding technology, applied in the direction of manufacturing tools, drilling tool accessories, metal processing equipment, etc., can solve the problems of increasing manufacturing costs, consuming tungsten carbide steel, increasing manpower, material resources and costs, and reducing production costs, The effect of saving manpower and improving processing accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

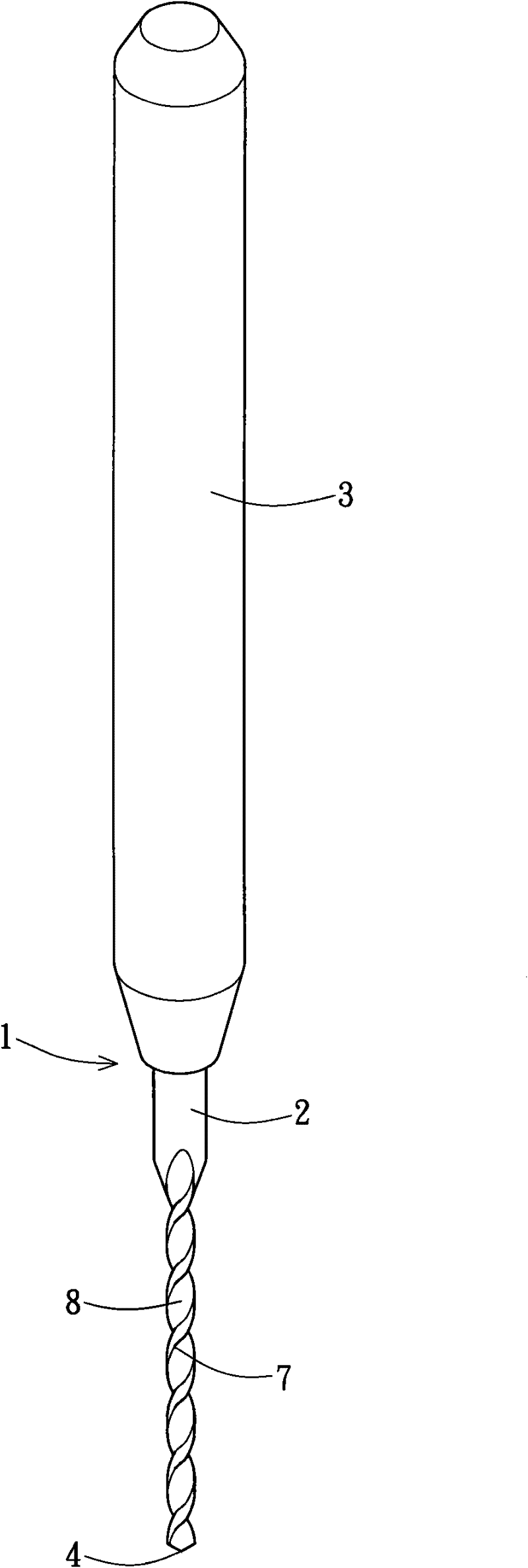

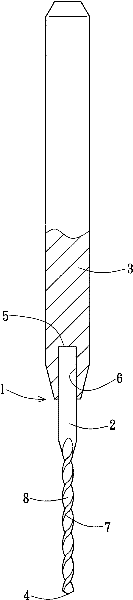

[0042] Relevant present invention is to achieve above-mentioned purpose, adopts technical means and effect thereof, enumerates feasible embodiment hereby, and cooperates accompanying drawing to illustrate as follows:

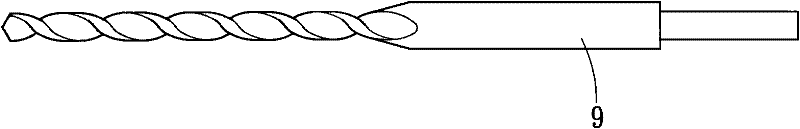

[0043] First, see figure 1 and figure 2 , the present invention is mainly aimed at cutting tools 1 such as a drill bit and a helical end mill, especially a micro drill bit for drilling a circuit board as shown in the figure. The powder sintering molding method of the cutting tool 1 and its cutting body 2 of the present invention is used to make a cutting body 2 (drill body) that contains one end 4 and the opposite end rod end 5. The helical cutting edge 7 and chip flute 8 , and the cutting body 2 is directly inserted into the hole 6 of the shank body 3 with the rod end 5 , forming a cutting tool 1 . In addition, the present invention can also be as Figure 9 As shown, the cutting body 17 is produced by powder sintering and the shank body 18 is integrally sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com