Surfactant for displacing oil and preparation method

A surfactant and oil displacement technology, applied in the field of tertiary oil recovery, can solve the problems of ultra-low interfacial tension concentration range and narrow salinity range, complex production process, unacceptable oil field, etc. Good stability and strong salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

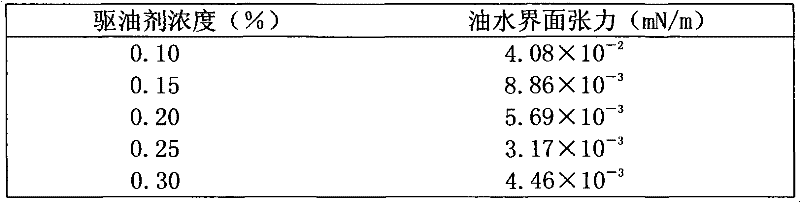

Embodiment 1

[0027] (1), preparation of residual oil sulfonate

[0028] First, add the remaining amount of vacuum residue into the reaction kettle, start stirring, heat up to 45°C, and then introduce 6% SO 3 Carry out sulfonation reaction, when the reaction is complete and the temperature no longer rises, age for 1 hour and keep the temperature at about 45°C, then add 8% isopropanol and stir evenly, and finally slowly add 15% hydrogen with a concentration of 30% dropwise The sodium oxide solution was neutralized. During the reaction, the temperature was controlled not to exceed 55°C. After the reaction was completed, the mixture was stirred for 1.0 hour to obtain the residual oil sulfonate.

[0029] (2), the preparation of intermediate sodium octylphenol sulfonate

[0030] First, add 0.3 mol of octylphenol into the reaction kettle, and pass 0.5 mol of SO at 40°C 3 The sulfonation reaction is carried out, and after the reaction is completed, a 30% solution containing 0.5 mol of NaOH is ad...

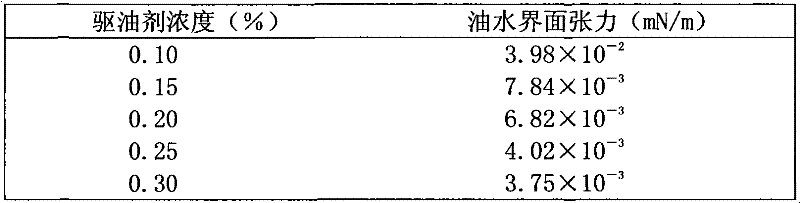

Embodiment 2

[0047] (1), preparation of residual oil sulfonate

[0048] First, add the remaining amount of vacuum residue into the reaction kettle, start stirring, heat up to 45°C, and then feed 10% SO 3 Carry out sulfonation reaction, when the reaction is complete and the temperature no longer rises, age for 1 hour and keep the temperature at about 45°C, then add 9% isopropanol and stir evenly, and finally slowly add 20% hydrogen with a concentration of 30% dropwise The sodium oxide solution was neutralized. During the reaction, the temperature was controlled not to exceed 55°C. After the reaction was completed, the mixture was stirred for 1.0 hour to obtain the residual oil sulfonate.

[0049] (2), the preparation of intermediate sodium octylphenol sulfonate

[0050] First, add 0.5 mol of octylphenol into the reaction kettle, and pass 0.8 mol of SO at 40°C 3 The sulfonation reaction is carried out, and after the reaction is completed, a 30% solution containing 0.8 mol of NaOH is added dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com