Triarylamine hole transport material and preparation method thereof

A hole-transporting material, triarylamine technology, applied in luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems affecting device life and performance, easy crystallization, and low film morphological stability. The effect of improving stability, good stability and reducing energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

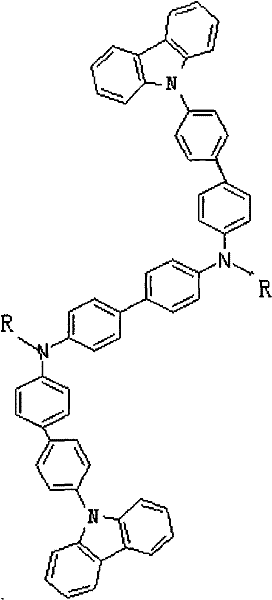

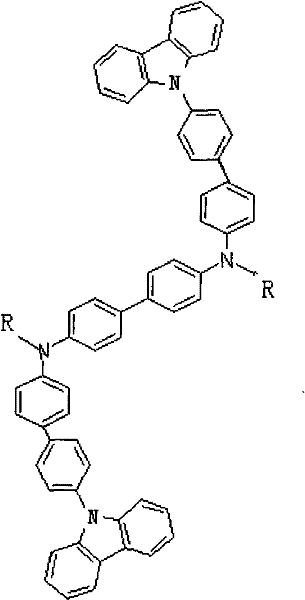

[0017] The triarylamine hole transport material compound of the present invention:

[0018]

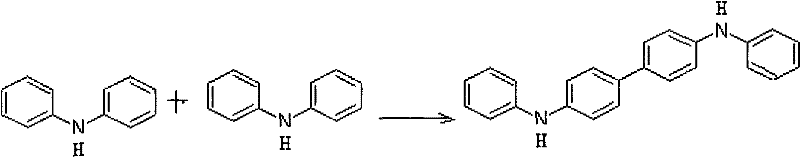

[0019] The method for preparing the R group at the N position as a phenyl group is as follows:

[0020] (1) Take N,N-diphenylamine as raw material and carry out Ullmann reaction with p-bromoiodobenzene under certain conditions to synthesize N,N'-diphenyl-N,N'-bis(4-bromobenzene) Group)-1,1'-biphenyl-4,4'-diamine.

[0021] The specific preparation method is:

[0022] a) In a 1L four-necked flask, add 200 grams of acetic acid, 400 ml of water, 150 grams of sulfuric acid, and 0.4 mol of diphenylamine. Stir and cool down to 5 degrees, slowly add 0.2mol of potassium dichromate saturated aqueous solution dropwise, after the dropwise addition is complete, stir at this temperature for half an hour, then filter and wash, the crude product is recrystallized with dimethylformamide and toluene. 20 g (HPLC: 98.5%) of N,N-diphenylamine, a white-like fine product.

[0023] The specific synthesis route is a...

Embodiment 2

[0042] The triarylamine hole transport material compound of the present invention:

[0043]

[0044] The R group at the N position is the preparation method of alkylbenzene, which is basically the same as the preparation method of Example 1, except that the raw material N,N-diphenylamine in step (1) is used as alkylbenzene biphenyl. Diamine substitution.

[0045] The advantages of the triarylamine hole transport material and the preparation method thereof of the present invention are as follows:

[0046] 1. The triarylamine hole transport material of the present invention has changed the disadvantages of low crystallinity of conventional hole transport materials, and the material is not conducive to crystallization. It can form a better amorphous state during the evaporation process, which is conducive to film shape. The appearance is flat, which improves the coating yield and reduces the cost.

[0047] 2. The catalyst used in the preparation method of the triarylamine hole transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com