Method for using sludge to produce coal gas

A sludge and gas technology, which is applied in the direction of pyrolysis treatment of sludge, granular/powdered fuel gasification, etc., can solve the problems of large waste of water resources, low calorific value of sludge and coal slurry, and high cost of sludge disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in combination with specific embodiments.

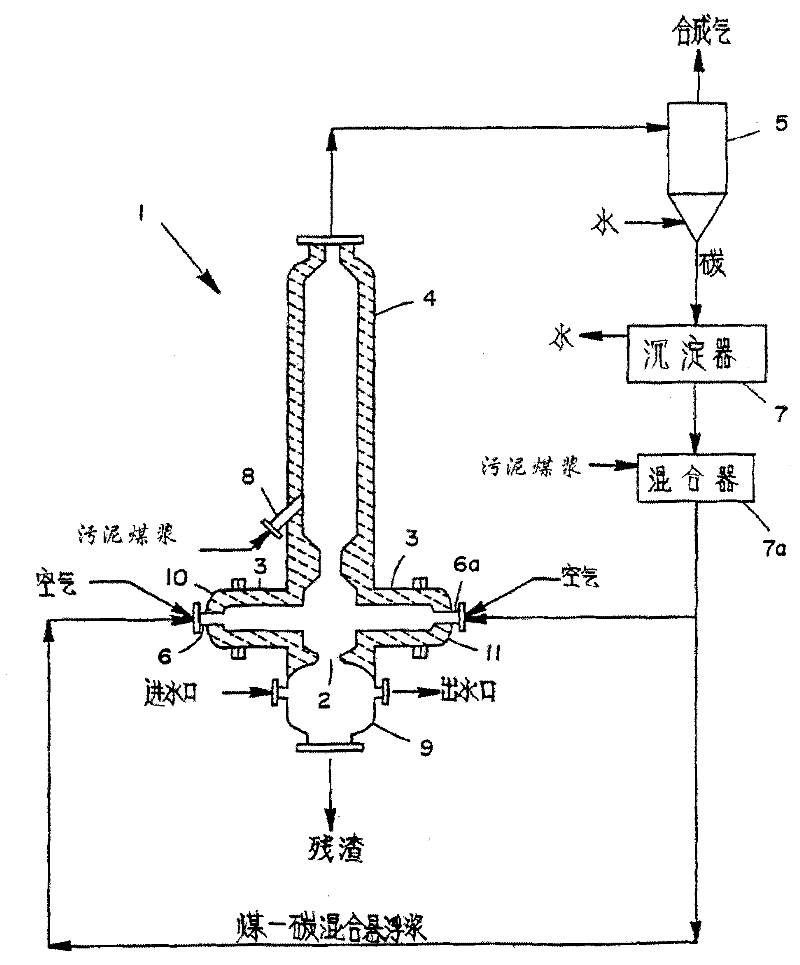

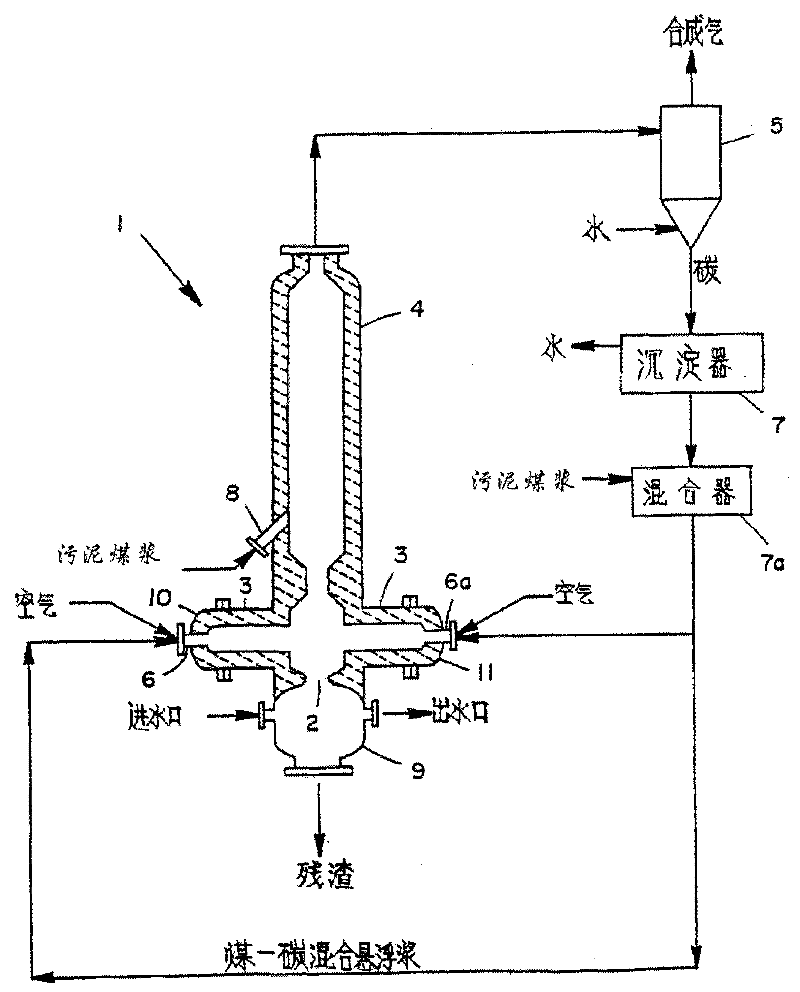

[0028] The primary innovation of the present invention is to use sludge as the main raw material or one of the main raw materials to prepare gas. And usually the following three specific ways can be used to prepare gas from sludge: 1) prepare gas from sludge coal slurry; 2) directly send sludge into the gasifier to burn with other fuels and react to generate gas; and 3) Separately dry the sludge and send it directly into the gasifier for combustion and reaction to generate coal gas.

[0029] The method for producing coal gas according to the first embodiment of the present invention includes the following steps: 1) making sludge coal slurry with sludge and coal; and 2) sending the sludge coal slurry into the gasifier to make the sludge Coal slurry and gasification agent undergo combustion reaction and gasification reaction to generate coal gas.

[0030]Apparently, the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com