Carbon fiber packaged optical fiber Bragg grating sensor and manufacturing method thereof

A fiber Bragg and grating sensor technology, which is applied in the use of optical devices to transmit sensing components, installation, optics, etc., can solve the problems of unsatisfactory sensor data linearity, complicated installation, protection and debugging, and unsatisfactory sensitivity. Excellent sensing characteristics, low cost of materials, improved sensitivity and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

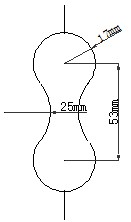

[0044] The fiber grating is packaged in a small sheet of carbon fiber. The specific method of packaging is to remove a carbon fiber material of sufficient size, cover the non-functional surface with tape for easy cutting, and cut out two peanut-shaped carbon fiber sheets through the template. Since the carbon fiber sheet is required to cover the entire FBG, the distance between the upper and lower centers of the carbon fiber sheet is required to be greater than 50mm, but its width can be arbitrarily widened according to actual needs. Apply resin glue evenly on the carbon fiber functional surface, apply a certain prestress to the fiber grating, straighten and fix it on one of the carbon fiber symmetry lines, then cover it with another piece of carbon fiber, and then press and fix the two pieces of carbon fiber for 72 hours That's it. In application,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com