Light-emitting device package component

A technology for light-emitting devices and packaging components, which is applied to electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of decreased heat dispersion efficiency, the chip area occupied by electrodes 10, and the reduction of the total chip area, and achieves the effect of high heat dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

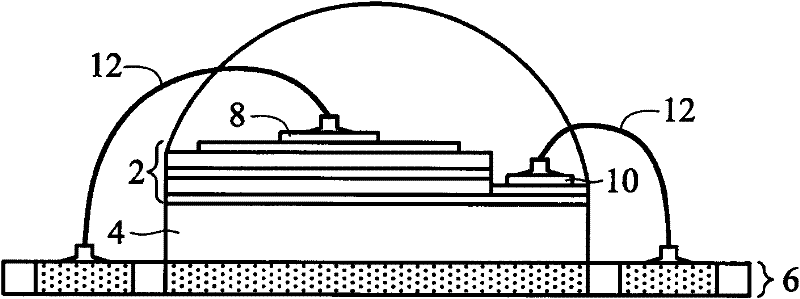

[0047] The present invention provides a novel light-emitting device (light-emitting device, LED) package component (package component) and a forming method thereof. Here, an example of an intermediate stage of the process is disclosed, followed by a discussion of different examples. In different views and illustrated embodiments, similar numerals are used to designate similar elements.

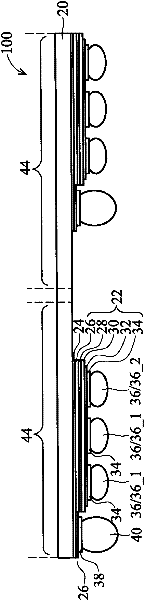

[0048] figure 2 A wafer 100 is disclosed that includes light emitting devices (LEDs) 22 formed on a substrate 20 . In one embodiment, the substrate 20 is made of sapphire (transparent aluminum oxide (Al 2 o 3 )), it can also be formed of other materials close to the characteristics of each layer in the light emitting device (LED) 22 (may include the third and fifth group elements or known compound semiconductor materials of the III-V group). The substrate 20 can also be a silicon carbide substrate, a silicon substrate with a silicon carbide layer thereon, a silicon germanium substrate or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com