Method for preparing high-content double-transition metal composite molecular sieve

A composite molecular sieve and transition metal technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor thermal stability and hydrothermal stability, etc., to increase the content, improve thermal stability and Hydrothermal stability, effect of increasing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

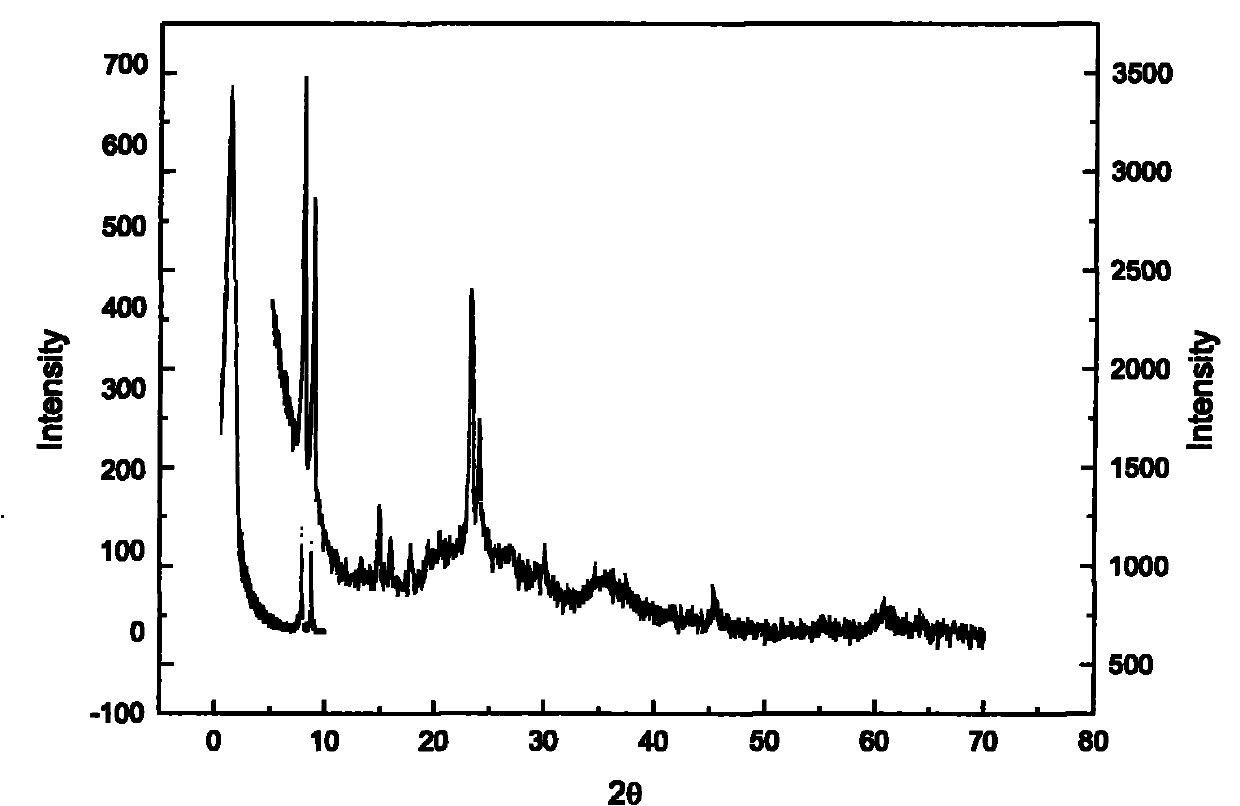

[0031] Weigh 2.97g of nickel nitrate and dissolve it in 10g of deionized water to react with sodium ethylenediaminetetraacetate solution to generate the metal complex Ni(EDTA) 2- . Then 12.089g of tetrabutylammonium bromide was weighed, the metal complex was mixed with water-soluble cationic surfactant tetrabutylammonium bromide, and the resulting template association was used as the template for the experiment.

[0032] Weigh 0.5g of sodium hydroxide and dissolve it in 20g of deionized water and stir. After dissolving, dissolve 3g of silicon dioxide weighed in the solution of sodium hydroxide. After stirring for 1 hour, add template agent [TBA] + 2 [Ni(EDTA) 2- ], and then continued to stir for 1.5 hours, using sodium hydroxide solution to adjust the pH to 9. Finally, the total amount of water was adjusted to 121ml, and the above synthesis process was carried out at room temperature. After 3 hours of continuous stirring, the obtained gel was transferred into a polytetrafl...

Embodiment 2

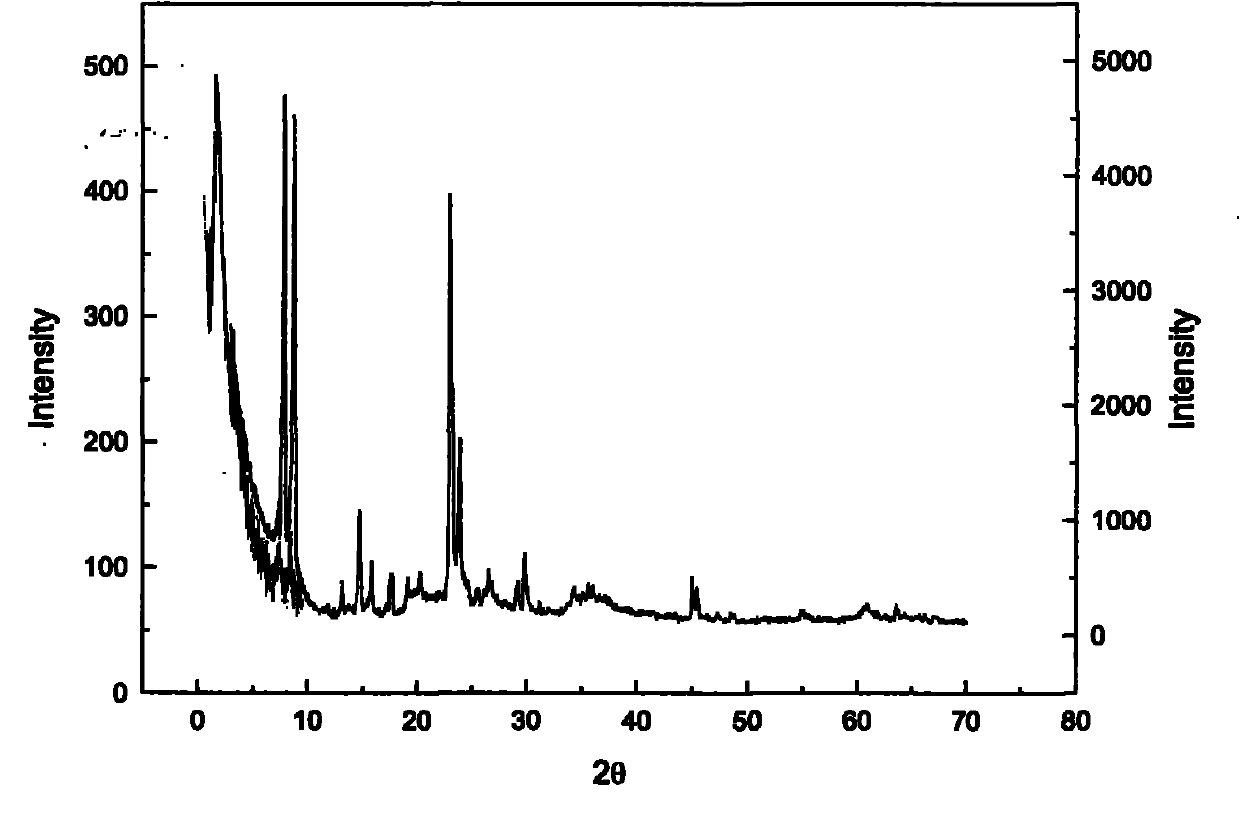

[0035] Dissolve 2.97g of nickel nitrate in 10ml of disodium ethylenediaminetetraacetic acid aqueous solution to generate metal complex Ni(EDTA) 2- . Then 12.089g of tetrabutylammonium bromide was weighed, the metal complex was mixed with water-soluble cationic surfactant tetrabutylammonium bromide, and the resulting product was used as a template for the experiment.

[0036] Weigh 0.5g of sodium hydroxide and dissolve it in 20g of deionized water and stir. After dissolving, dissolve 3g of silicon dioxide weighed in the solution of sodium hydroxide. After stirring for 1 hour, add template agent [TBA] + 2 [Ni(EDTA) 2- ], and then continued to stir for 1.5 hours, using sodium hydroxide solution to adjust the pH to 9. Finally, adjust the total amount of water to 121ml. The above synthesis process was carried out at room temperature, and after continuous stirring for 3 hours, the obtained gel was transferred into a polytetrafluoroethylene-lined reaction tank, statically crystal...

Embodiment 3

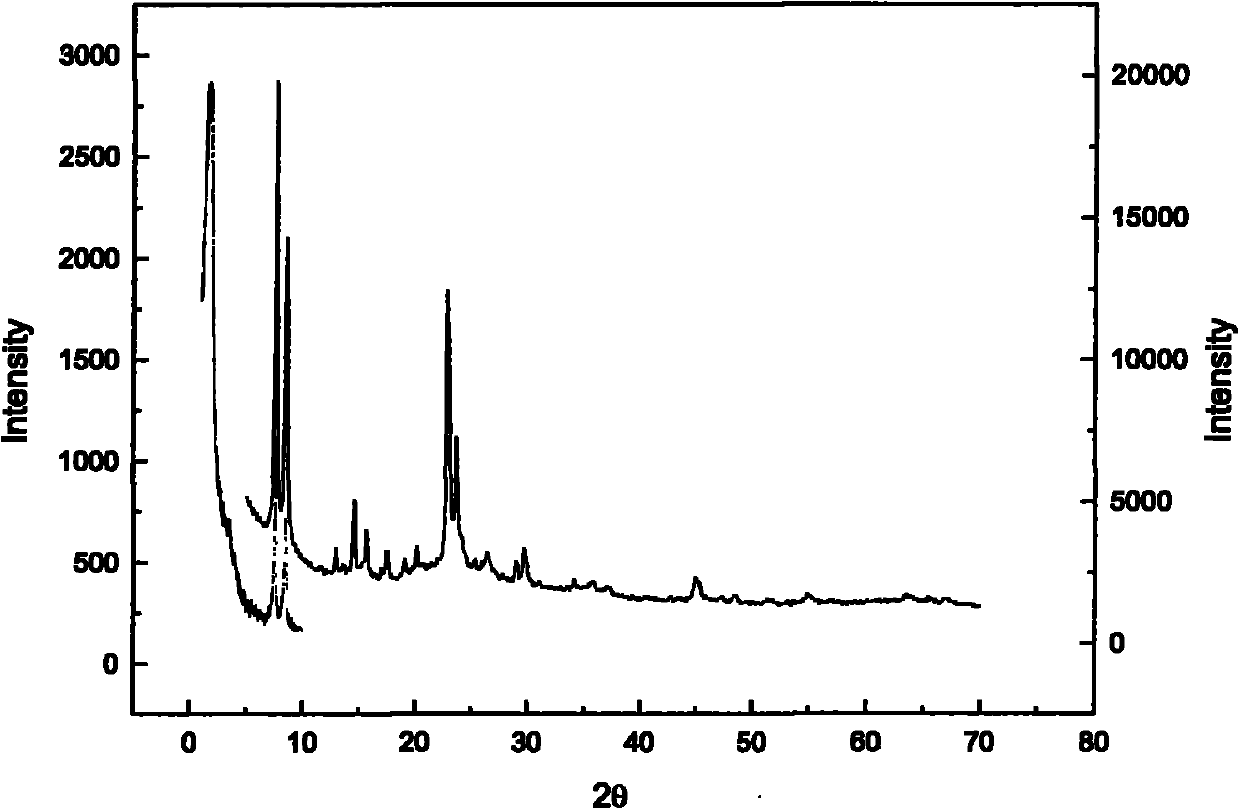

[0039] Weigh 2.99g of cobalt nitrate and dissolve it in 10g of deionized water to react with sodium edetate solution to generate the metal complex Ni(EDTA) 2- . Then 12.089g of tetrabutylammonium bromide was weighed, the metal complex was mixed with water-soluble cationic surfactant tetrabutylammonium bromide, and the resulting template association was used as the template for the experiment.

[0040] Weigh 0.5g of sodium hydroxide and dissolve it in 20g of deionized water and stir. After dissolving, dissolve 3g of silicon dioxide weighed in the solution of sodium hydroxide. After stirring for 1 hour, add template agent [TBA] + 2 [Co(EDTA) 2-], and then continued to stir for 1.5 hours, using sodium hydroxide solution to adjust the pH to 9. Finally, the total amount of water was adjusted to 121ml, and the above synthesis process was carried out at room temperature. After 3 hours of continuous stirring, the obtained gel was transferred into a polytetrafluoroethylene-lined re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com