Steam catapult for carrier-borne aircraft and catapulting method thereof

A carrier-based aircraft and catapult technology, applied in the direction of launching/dragging transmissions, etc., can solve the problems of high maintenance costs, fixed ejection speed, and increased difficulty in cylinder processing, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

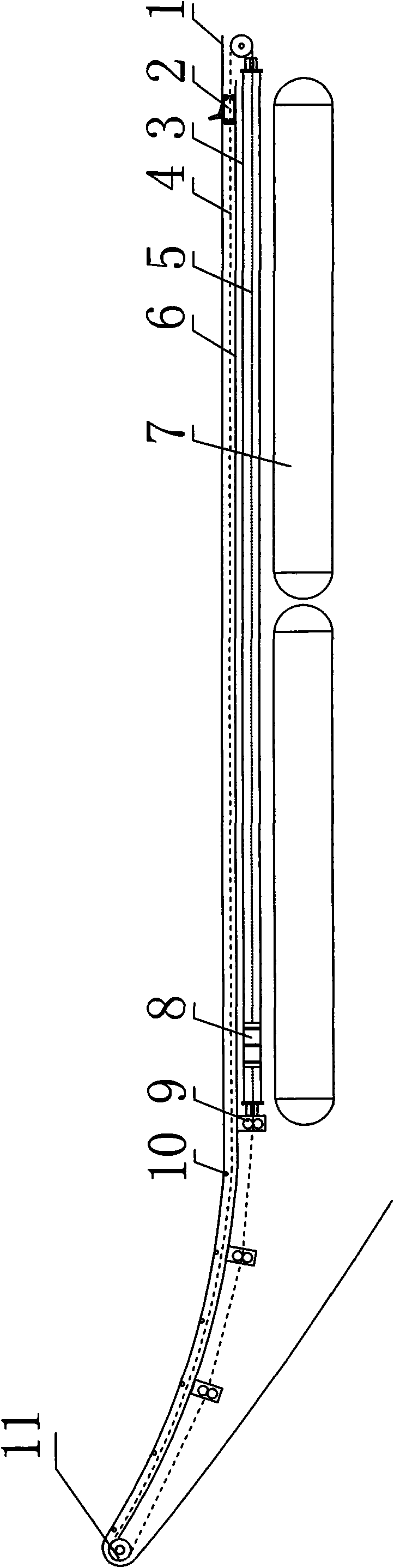

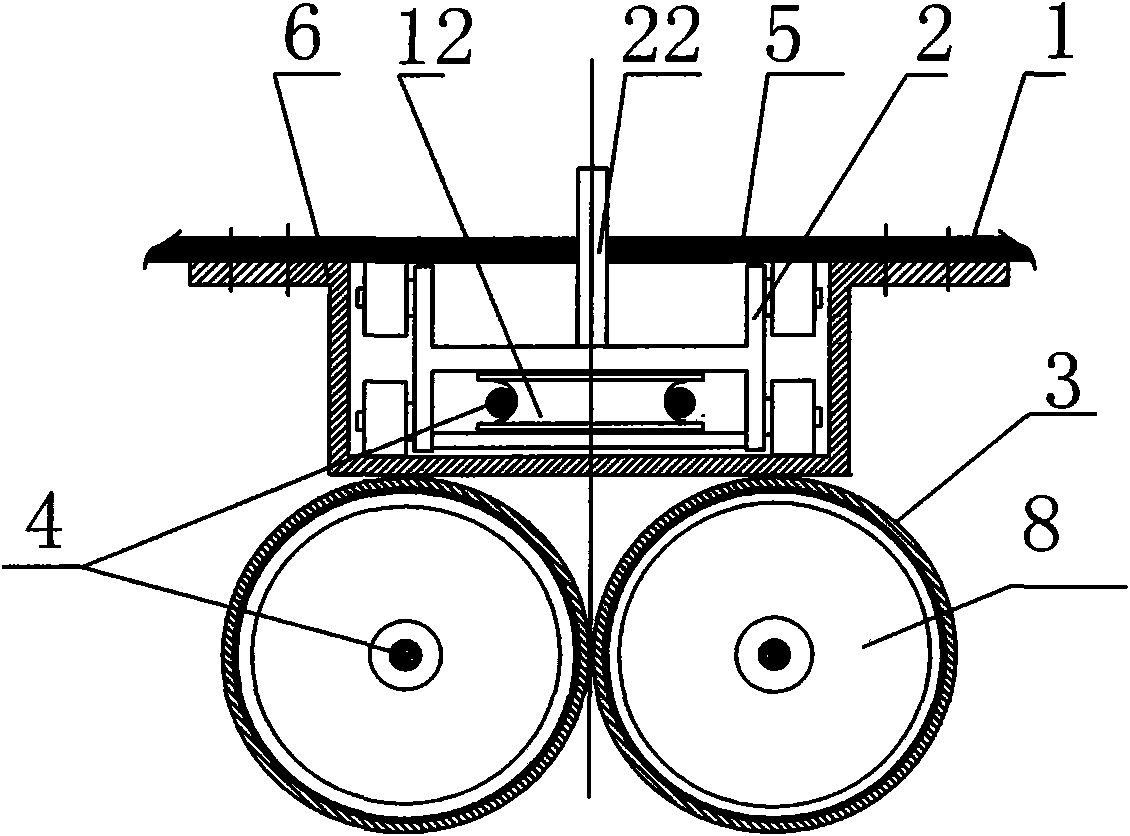

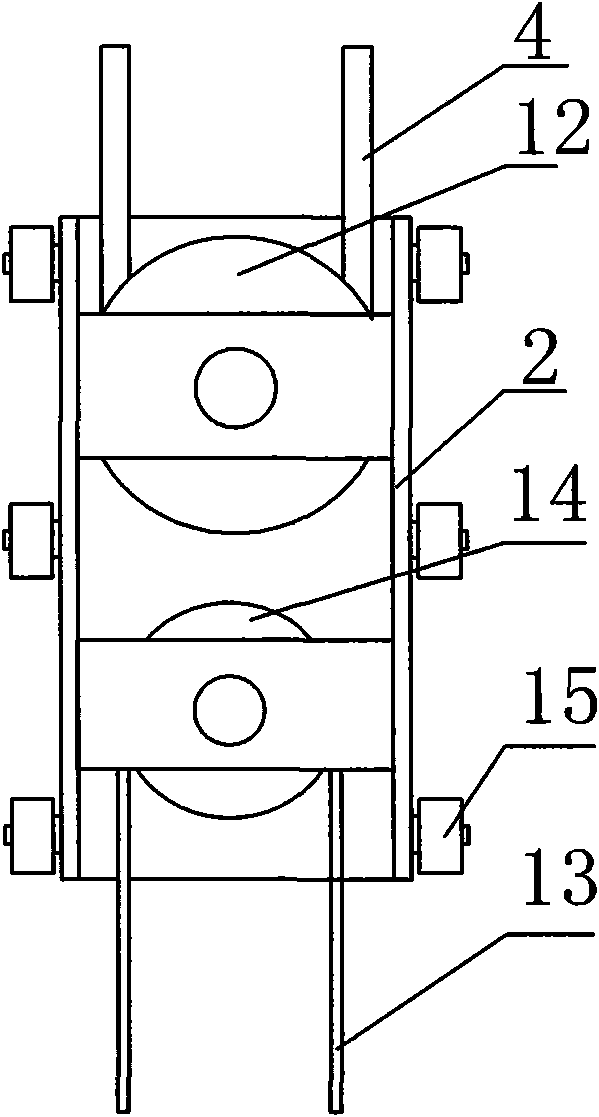

[0029] With reference to accompanying drawing, the steam catapult of aircraft carrier and its ejection method are described in detail below.

[0030] As shown in the accompanying drawings, the steam catapult for carrier-based aircraft of the present invention has a structure consisting of a take-off runway 1, a tackle 2, a tackle passage, a cylinder 3 and an ejection program controller, wherein the cylinder 3 is composed of Ejection cylinder 3 and damping cylinder 19 are composed, and damping cylinder 19 is connected to the end of piston ejection stroke, and the tackle channel is set in the middle of take-off runway 1, and tackle 2 is arranged in the tackle channel, and cylinder is arranged under the tackle channel, and the tackle 2 The bottom is provided with a traction cable balance pulley 12 and a return cable balance pulley 14, the middle of the traction cable 4 is wound on the traction cable balance pulley 12, and the two ends of the traction cable 4 pass through the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com