Method for preparing photoinduced ultra hydrophilic automatically cleaning paint

A super-hydrophilic, self-cleaning technology, applied in coatings and other directions, can solve the problems of inapplicable preparation methods and products, inconvenient use, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

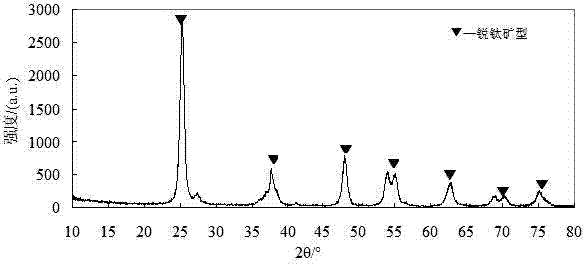

Image

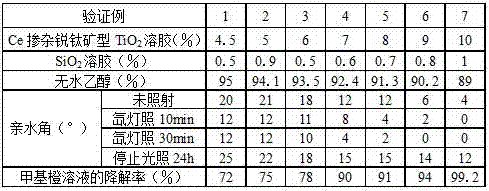

Examples

Embodiment Construction

[0018] A preparation method of a photoinduced superhydrophilic self-cleaning coating, the method comprising the steps of:

[0019] ① Disperse titanium hydroxide in distilled water, gradually add hydrogen peroxide solution with a mass fraction of 30% and stir thoroughly to obtain a titanium dioxide suspension;

[0020] Among them, titanium hydroxide: distilled water = 1.5g: 100mL (during industrial production, it is converted according to this ratio, the same below);

[0021] ② Gradually drop the cerium nitrate solution with a mass fraction of 1% into the titanium dioxide suspension obtained in step ①, and stir under microwave heating conditions to obtain cerium-doped anatase titanium dioxide sol, and set aside;

[0022] Among them, titanium dioxide suspension: cerium nitrate solution with a mass fraction of 1% = 106g: 0.5mL; the microwave frequency is 2450MHz, the microwave power is 800W, the heating temperature is 90°C, and the heating time is 90min;

[0023] ③ Put anhydrous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com